- Joined

- Oct 27, 2005

- Messages

- 3,682

- Reaction score

- 1,378

- Points

- 337

- Location

- South Yorks, UK

- Printer Model

- Epson, Canon, HP... A "few"

... and then you remember who is running for president.. *steps away from the very large minefield*rodbam said:Excellent information here that I'm carefully reading because there was a special on the Pro9500 bundled with $300 of Canon A3 paper so my missus made me buy one for $699, yes for once I wish I was a Yank

"Safest" would be the dribble method in the sense of slow and sure but if you're starting from scratch on most cartridges you're going to be talking quite a long haul... and to get the best of both worlds a combined force-fill + dribble top-up seems to be a good option.Now what is my safest refill method to begin with, dribble or the Freedom method?

If you dribble ink in then the air is slowly forced out and you would only see this if you somehow managed to flood the cartridge sponge enough for a bubble to appear on the sponge surface. Given the surface area size that's unlikely so it's not visually obvious what's going on.The thing that confuses me after watching the Hats & (Joe) Jtoolman excellent videos is the sucking out of air, in Joe's video he didn't suck air out before filling on a half full cart but the Hat sucked air out from an empty cart. What would happen if you just injected ink in without sucking out first?

With the force fill (what I believe you are calling the "freedom method") if the air wasn't removed first you would be forcing ink in but not allowing air to escape so you wouldn't be able to just push ink in and expect the cartridge to be full of ink when you hit resistance. Instead you would have to withdraw pressure (with the cartridge up-ended) to allow air to be pulled out and then repeat ingress of ink until you were sure that the cartridge contained only ink and not air.

As a result, removing the air first when force filling, is preferable as you don't have to do lots of push, pull, push, pull to get to full.

From memory almost all of the posts to just recently, mentioned filling only cartridges currently in use and flushing has just reared its head. As a result I don't think anyone really considered the ins and outs of flushing properly until now, in fact almost all flushing discussion has focused on how to get the sponge clear of any dried ink or clogging.The other thing that puzzles me is the cleaning/purging of these carts, I can understand how you put water in but how do you get the water out & get the cart almost dry? Edit. I've just read Martins bit about sucking the water out with a reverse of the Freedom method.

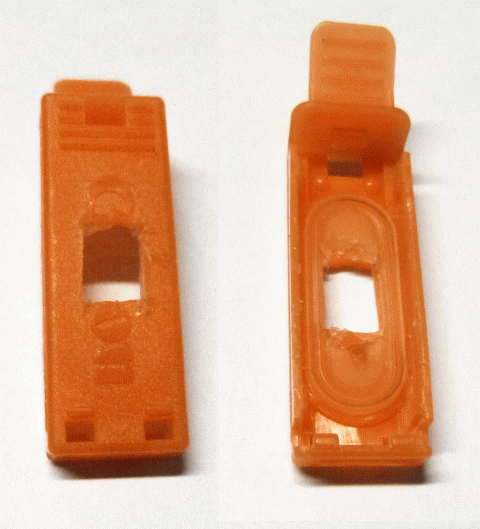

Pulling the ink out using a mod'd clip is IMHO the best approach (as noted) but the other way might be the one used with other Canon carts (ref ) but that would require the cartridge to right side up and be VERY slow/wasteful. The only other approach would require a more professional equipment setup (ie: vaccum pump and container) to purge the cartridges but to the same effect as the mod'd clip.

Note: Anticipating the come back on use of a mod'd clip... The sponge does need to be clear of junk/dried ink so the mod'd clip is only part of the equation. In terms of purging the cartridge it's the most sensible and cost (time & money) effective approach.

You feel the restriction.. I did try to over pressure the vacuum with a 60ml capacity syringe at one point and the bag held fine but obviously I wouldn't recommend that approach as it's going to cause stress over time. Common sense would seem to apply in how you deal with it... ie: don't go crazy!Does this sucking pull the bag in too tight on itself if you over suck, or is the restriction you feel in the syringe all that's needed for not overdoing it?

Well the hiccuping and slurred typing was a tad off puttingI will be sober in the morning when I read your replies so can you reply whilst still sober, thank you.