- Thread starter

- #11

- Joined

- Feb 24, 2005

- Messages

- 1,669

- Reaction score

- 183

- Points

- 223

- Location

- North of Boston, USA

- Printer Model

- Canon i9900 (plus 5 spares)

Before proceeding, unless you are a serious nerd you may want to skip this post. It's going to get more than a little technical.

JV,

Another interesting link.

I have not digested everything completely, but I am confused:

1. It is generally accepted that papers with swellable surfaces last longer than papers with nanoporous surfaces because they are more effective at blocking airborne contaminants (e.g. ozone).

2. Kodak says that they ozone in typical concentrations isn't a problem with their new paper because it is swellable, but they don't give any data on nanoporous papers, implying that it is a problem on nanoporous papers.

3. Livick states that blowing air across the prints has almost no effect, but they didn't test the samples behind glass. They also show very short lifetimes for some dye based inks on nanoporous papers, but longer lifetimes on swellable papers. Their test results aren't consistent with each other.

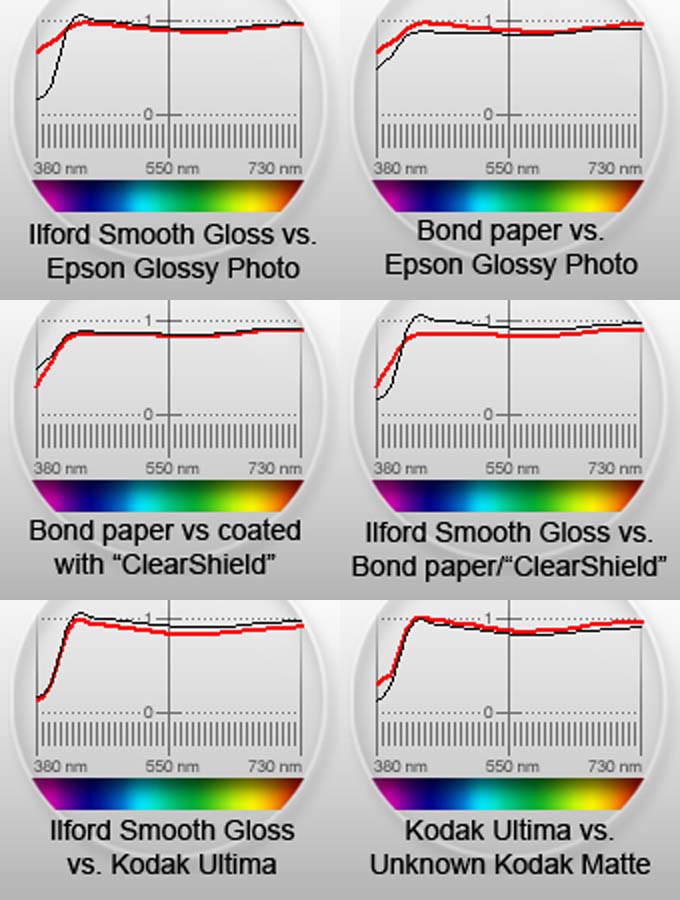

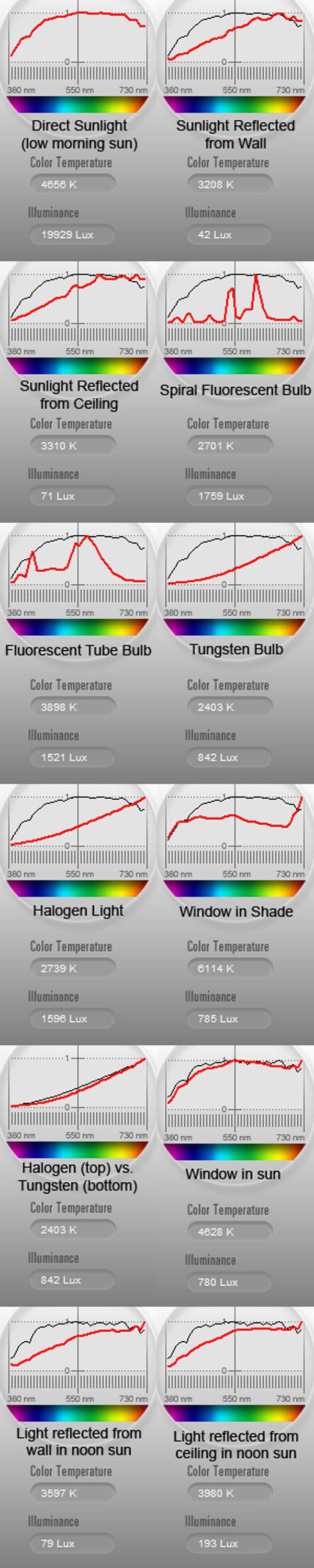

This morning, I got out my spectrophotometer and took some light readings at various places around the house. The results for 12 readings are given below. Before proceeding, let me explain what each image shows. For each test, I took a screenshot of a program to display the spectro's data, cropped it to a small section with the important information and combined 12 readings into a single image.

For each lighting condition the spectro takes 38 readings from 380 to 730 nm (nanometers; 1000 nm = 1 micron). Visible light is usually taken to be between 400 and 700 nm, so the far left of each chart is in the ultraviolet range (from 100 to 400 nm). Since UV light is what causes inks to fade, the left side is very important. As a point of reference, below 100 nm and we are into X-rays - it is easily seen why UV can be so harmful. The far right of each chart is the start of the Infrared (IR) spectrum, which includes radiated heat. A high value (near the "1" on the top) indicates that there is a lot of energy in the light at that wavelength; a low value (near the "0" on the bottom) indicates that there is very little energy in the light at that wavelength. The colors under the chart correspond to the color associated with that wavelength of light. Below the chart are the values for the "Color Temperature" of the light and its intensity, measured in "Lux".

The first chart shows the early morning light when the sun was low in the sky coming through my kitchen windows with all other lights turned off - the lighting was quite comfortable with just the sunlight. Note that the energy drops off at the right because glass absorbs (or is it reflects?) IR, progressively blocking it from entering the house. At about 20,000 Lux, the sun was not terribly bright at this time of the morning, but it was near the upper limit of my spectro (it doesn't generate readings above about 25,000 Lux - that isn't its intended purpose). In any case, this gives a baseline reading for the wavelengths present in direct sunlight. The high intensity and high content of UV in this light would do significant damage to a print. This chart was included on most of the other charts to provide a direct comparison with sunlight.

The second chart was measured about 10' away from a wall that had the sunlight shining on it; note that there was very little UV energy in this light and the intensity was only 42 Lux (Livick uses 275 Lux for 10 hours/day for their test baseline). The light reflected from this wall would do very little damage to a print. The third chart shows the light reflected from the white ceiling, and it is similar to the light from the wall.

The 4th and 5th charts show the light generated by two fluorescent bulbs - the 4th is a replacement screw-in bulb for a tungsten socket and the 5th is a pair of 18" long tube bulbs. As Livick states, there is very little UV energy in these lights, so they do not simulate sunlight very well. These readings were taken about 1' away from the lights, so they are well above the 275 Lux test baseline. It is interesting to note that there is very little IR energy generated by these bulbs. That is why they are so efficient - most of the energy goes into producing light.

Contrast this with the 6th and 7th charts for Tungsten and Halogen lights - most of the energy goes into generating heat (IR) instead of light. These charts show that Tungsten lights generate almost no UV, and that they should therefore cause very little damage to prints. Skipping ahead to chart 9, these two lights are directly compared. It can be seen that the Halogen puts out more light in the middle of the spectrum, and that is why it is more pleasing to the eye than a Tungsten light.

The 8th chart was taken from the light coming in through a window on the side of the house away from the sun. There is a lot of IR in this light, and almost the same percentage or UV as in direct sunlight. This says that prints facing any window will receive a lot more UV than prints that do not face a window, even if the sun doesn't directly shine through the window.

The 10th chart shows the light coming through a window in the mid-day sun, but not directly in the sunbeam. The spectrum is very similar to the direct morning sun, but at a much reduced light level. This light has a lot of UV and would damage a print. The 11th and 12th charts show the light reflected from a far wall and ceiling in the same room where the 10th chart was measured. As before, when the sunlight reflects from another surface the UV content is greatly reduced.

Summary:

1. Tungsten lights have a very low percentage of UV in their spectrum and should do little damage to prints.

2. Fluorescent lights have a little higher percentage of UV than tungsten lights, but still far less than sunlight. They should also do little damage to prints.

3. Direct sunlight has the highest percentage of UV, and will do the most damage. Even if the prints do not receive direct sunlight, any direct light through a window will have a high percentage of UV.

4. Sunlight that is reflected from the floor, ceiling or walls has about 1/2 of the percentage of UV as direct sun light, and will only cause 50% of the damage as direct sunlight (for the same Lux readings).

Observations:

1. While 275 Lux may be typical in a room where you are reading or working, most rooms in a house are not lit to that level with sunlight for 10 hours/day.

2. In my house, sunlit rooms are seldom more than 100 Lux where my prints are mounted, and that is only for a few hours/day and only on those days when the sun is shining. With artificial lighting, the prints see more than 100 Lux, but there is very little UV in that light. Also, the artificial lighting is seldom on for more than a few hours/day in a single location.

3. I never have photos in direct sunlight.

4. I have had dye based prints on the refrigerator for 3 years with no obvious fading.

5. The lighting is only one of many variables in determining print life, and all of these variables help to explain why some people don't have a fading problem while others do.

6. Only Livick addresses the differences in the UV content of the type of light used for the test, but they (IMHO incorrectly) assume that all light is the same as direct sunlight. In light of these readings, I feel that Livick's tests greatly understate the life of a print in a typical house.

JV,

Another interesting link.

I have not digested everything completely, but I am confused:

1. It is generally accepted that papers with swellable surfaces last longer than papers with nanoporous surfaces because they are more effective at blocking airborne contaminants (e.g. ozone).

2. Kodak says that they ozone in typical concentrations isn't a problem with their new paper because it is swellable, but they don't give any data on nanoporous papers, implying that it is a problem on nanoporous papers.

3. Livick states that blowing air across the prints has almost no effect, but they didn't test the samples behind glass. They also show very short lifetimes for some dye based inks on nanoporous papers, but longer lifetimes on swellable papers. Their test results aren't consistent with each other.

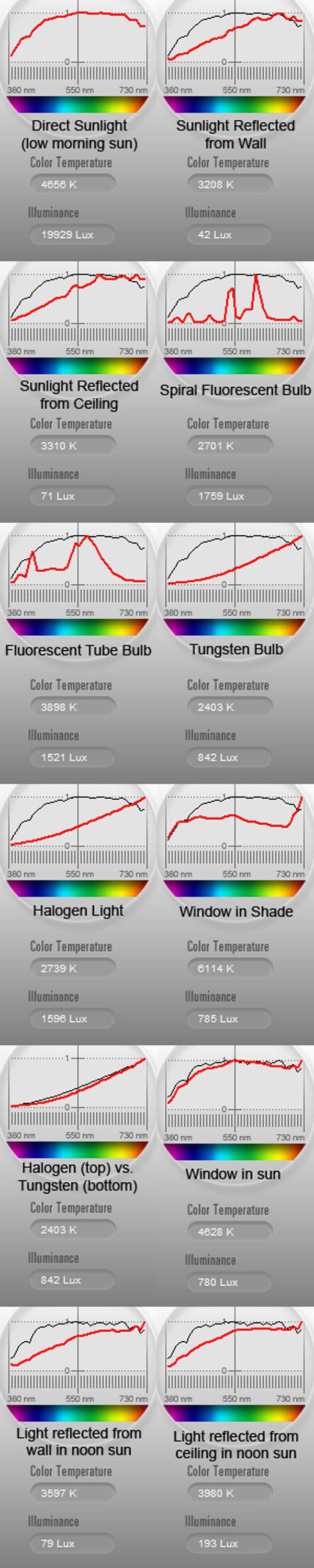

This morning, I got out my spectrophotometer and took some light readings at various places around the house. The results for 12 readings are given below. Before proceeding, let me explain what each image shows. For each test, I took a screenshot of a program to display the spectro's data, cropped it to a small section with the important information and combined 12 readings into a single image.

For each lighting condition the spectro takes 38 readings from 380 to 730 nm (nanometers; 1000 nm = 1 micron). Visible light is usually taken to be between 400 and 700 nm, so the far left of each chart is in the ultraviolet range (from 100 to 400 nm). Since UV light is what causes inks to fade, the left side is very important. As a point of reference, below 100 nm and we are into X-rays - it is easily seen why UV can be so harmful. The far right of each chart is the start of the Infrared (IR) spectrum, which includes radiated heat. A high value (near the "1" on the top) indicates that there is a lot of energy in the light at that wavelength; a low value (near the "0" on the bottom) indicates that there is very little energy in the light at that wavelength. The colors under the chart correspond to the color associated with that wavelength of light. Below the chart are the values for the "Color Temperature" of the light and its intensity, measured in "Lux".

The first chart shows the early morning light when the sun was low in the sky coming through my kitchen windows with all other lights turned off - the lighting was quite comfortable with just the sunlight. Note that the energy drops off at the right because glass absorbs (or is it reflects?) IR, progressively blocking it from entering the house. At about 20,000 Lux, the sun was not terribly bright at this time of the morning, but it was near the upper limit of my spectro (it doesn't generate readings above about 25,000 Lux - that isn't its intended purpose). In any case, this gives a baseline reading for the wavelengths present in direct sunlight. The high intensity and high content of UV in this light would do significant damage to a print. This chart was included on most of the other charts to provide a direct comparison with sunlight.

The second chart was measured about 10' away from a wall that had the sunlight shining on it; note that there was very little UV energy in this light and the intensity was only 42 Lux (Livick uses 275 Lux for 10 hours/day for their test baseline). The light reflected from this wall would do very little damage to a print. The third chart shows the light reflected from the white ceiling, and it is similar to the light from the wall.

The 4th and 5th charts show the light generated by two fluorescent bulbs - the 4th is a replacement screw-in bulb for a tungsten socket and the 5th is a pair of 18" long tube bulbs. As Livick states, there is very little UV energy in these lights, so they do not simulate sunlight very well. These readings were taken about 1' away from the lights, so they are well above the 275 Lux test baseline. It is interesting to note that there is very little IR energy generated by these bulbs. That is why they are so efficient - most of the energy goes into producing light.

Contrast this with the 6th and 7th charts for Tungsten and Halogen lights - most of the energy goes into generating heat (IR) instead of light. These charts show that Tungsten lights generate almost no UV, and that they should therefore cause very little damage to prints. Skipping ahead to chart 9, these two lights are directly compared. It can be seen that the Halogen puts out more light in the middle of the spectrum, and that is why it is more pleasing to the eye than a Tungsten light.

The 8th chart was taken from the light coming in through a window on the side of the house away from the sun. There is a lot of IR in this light, and almost the same percentage or UV as in direct sunlight. This says that prints facing any window will receive a lot more UV than prints that do not face a window, even if the sun doesn't directly shine through the window.

The 10th chart shows the light coming through a window in the mid-day sun, but not directly in the sunbeam. The spectrum is very similar to the direct morning sun, but at a much reduced light level. This light has a lot of UV and would damage a print. The 11th and 12th charts show the light reflected from a far wall and ceiling in the same room where the 10th chart was measured. As before, when the sunlight reflects from another surface the UV content is greatly reduced.

Summary:

1. Tungsten lights have a very low percentage of UV in their spectrum and should do little damage to prints.

2. Fluorescent lights have a little higher percentage of UV than tungsten lights, but still far less than sunlight. They should also do little damage to prints.

3. Direct sunlight has the highest percentage of UV, and will do the most damage. Even if the prints do not receive direct sunlight, any direct light through a window will have a high percentage of UV.

4. Sunlight that is reflected from the floor, ceiling or walls has about 1/2 of the percentage of UV as direct sun light, and will only cause 50% of the damage as direct sunlight (for the same Lux readings).

Observations:

1. While 275 Lux may be typical in a room where you are reading or working, most rooms in a house are not lit to that level with sunlight for 10 hours/day.

2. In my house, sunlit rooms are seldom more than 100 Lux where my prints are mounted, and that is only for a few hours/day and only on those days when the sun is shining. With artificial lighting, the prints see more than 100 Lux, but there is very little UV in that light. Also, the artificial lighting is seldom on for more than a few hours/day in a single location.

3. I never have photos in direct sunlight.

4. I have had dye based prints on the refrigerator for 3 years with no obvious fading.

5. The lighting is only one of many variables in determining print life, and all of these variables help to explain why some people don't have a fading problem while others do.

6. Only Livick addresses the differences in the UV content of the type of light used for the test, but they (IMHO incorrectly) assume that all light is the same as direct sunlight. In light of these readings, I feel that Livick's tests greatly understate the life of a print in a typical house.