- Joined

- Feb 24, 2005

- Messages

- 1,669

- Reaction score

- 182

- Points

- 223

- Location

- North of Boston, USA

- Printer Model

- Canon i9900 (plus 5 spares)

I thought that it might be interesting to look at the surface of a few inkjet papers, so I put 3 Ilford inkjet papers under a microscope:

Classic Pearl - 240 GSM swellable satin finish suitable only for dye based inks (slow drying)

Smooth Pearl - 290 GSM nanoporous satin finish suitable for dye and pigmented inks (instant dry)

Smooth Gloss - 280 GSM nanoporous glossy finish suitable for dye and pigmented inks (instant dry)

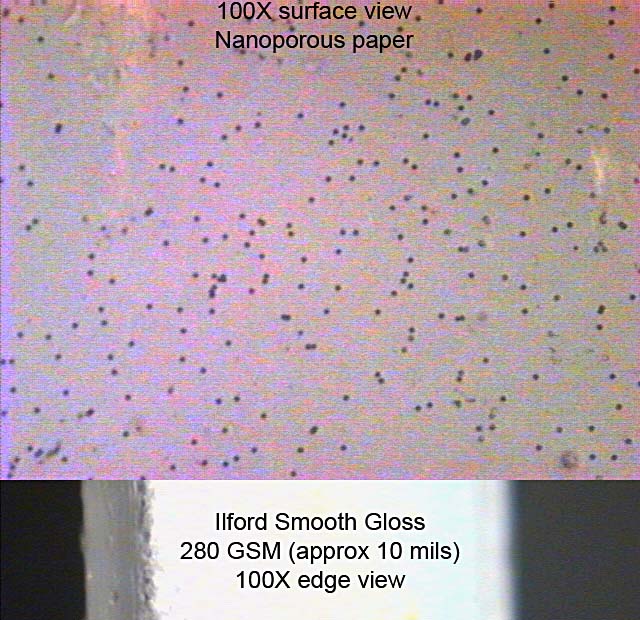

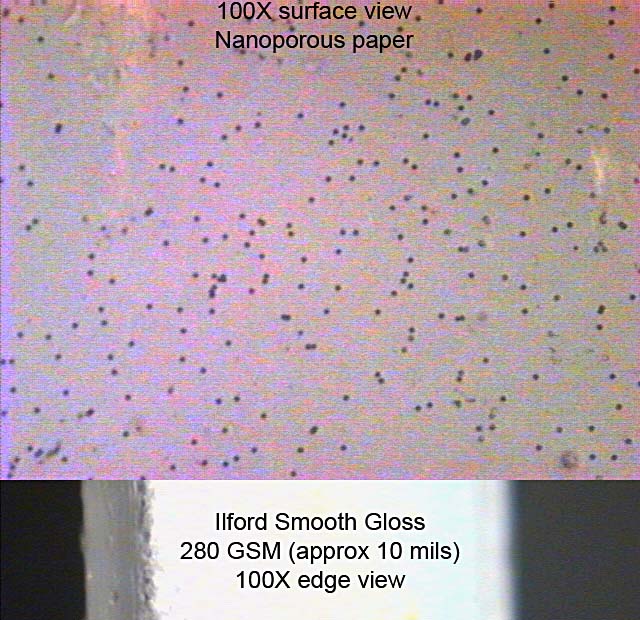

This image shows the Smooth Gloss paper, with the printable surface on the top and a segment of an edge view on the bottom. The printable surface is on the left of the bottom image - there is a similar coating on the uncoated side, but it was out of focus on this image. Since the paper is about 10 mils (250 microns) thick, it gives a good reference for the scale of the images. The term "nanoporous" implies that there should be small holes in the surface for ink to wick into the paper, and there appear to be multiple (approximately 10 micron diameter) holes in the surface. It was very difficult to focus on the holes, as the holes don't appear to be well defined. The holes appeared sharper when viewed through the stereo eyepieces, but since this image is from only one source it is not as sharp. It was also interesting that the holes were not nearly as visible at higher magnifications, apparently because the depth of field at those magnifications was too short to pick up the poorly defined holes. Note that the contrast has been greatly increased on these images to bring out the details of the holes - they are not nearly as obvious in the microscope or on the original. For another comparison, this post (http://www.nifty-stuff.com/forum/viewtopic.php?id=392) shows the ink dots after they spread out on the paper at almost the same magnification.

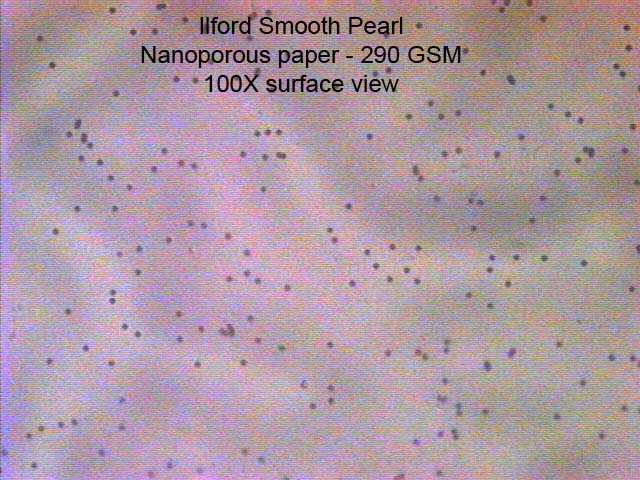

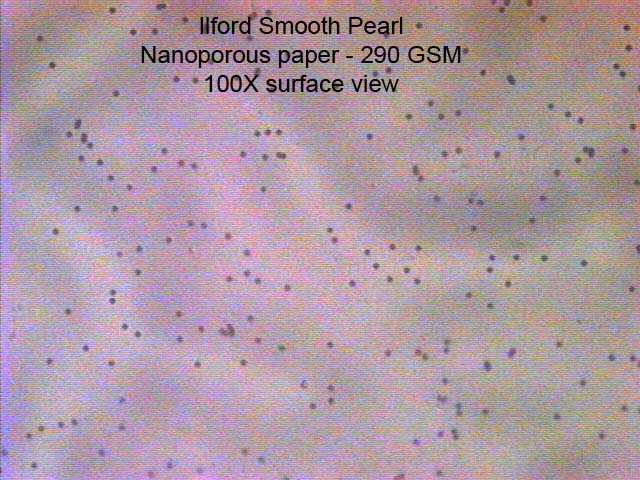

This image shows the Smooth Pearl paper. It has similar holes in the surface, and also an irregular (larger scale) surface pattern that gives the paper its satin finish.

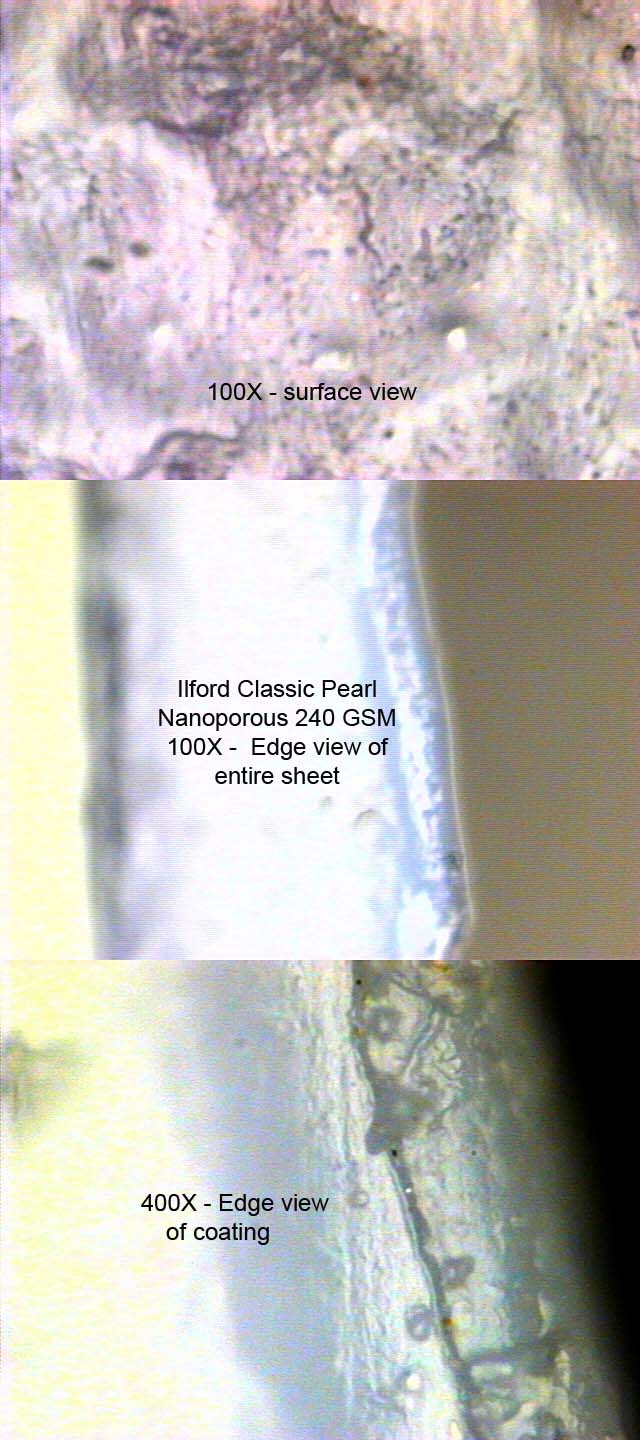

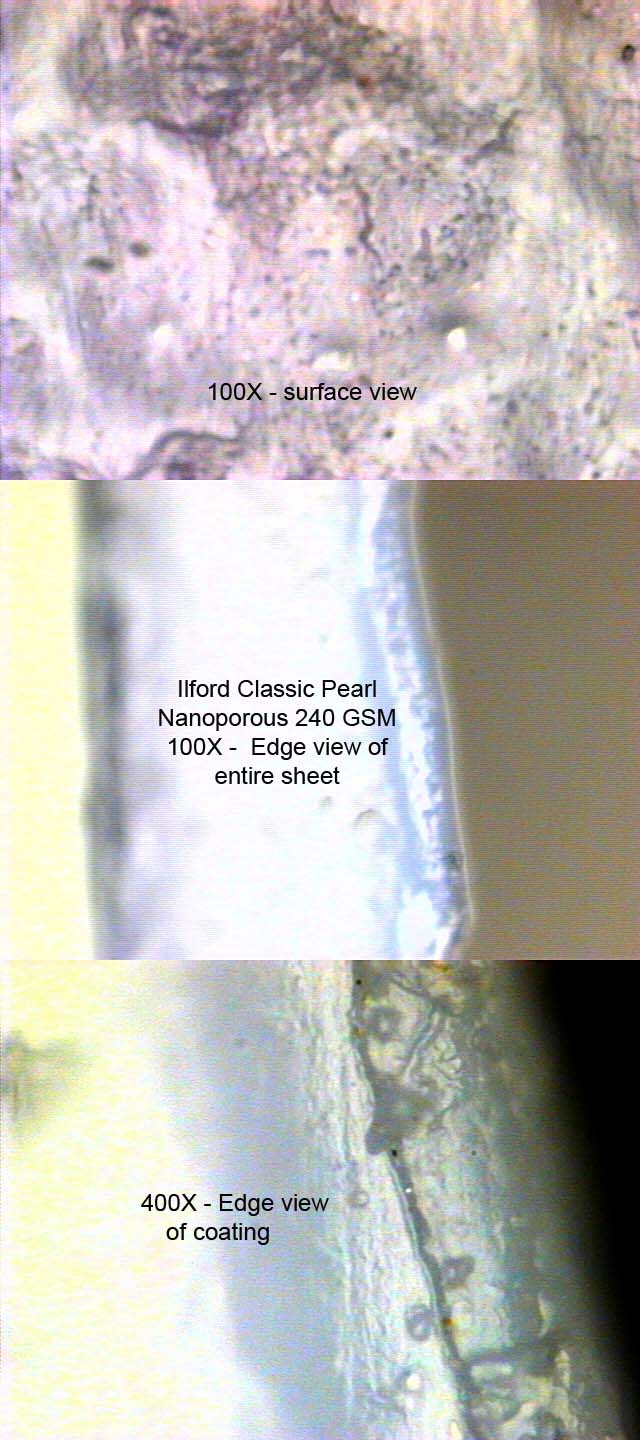

This shows three views of the Classic Pearl paper. The top is a similar view as given for the other two papers. Since it is "swellable", it isnt expected to have holes in the surface, and it doesn't. It shows similar ripples from the satin finish, but there is a lot of small scale surface roughness that was not seen with the Smooth Pearl paper. The middle is an edge view, showing that the thickness of the paper varies due to the satin finish (the printable surface is on the right on this image). By way of an explanation of why the focus is so bad, these papers have very soft coatings, and they don't cut cleanly even with a new razor blade (the usual technique is to freeze them in dry ice or even liquid nitrogen before cutting them). The resulting smeared surface is at varying heights that can't all be in focus at once. The bottom part is a close up (at 4x the magnification of the other shots) of just the swellable coating. The swellable coating appears to be made from at least two main layers, and it appears to have another very thin layer between them.

If anyone has access to a scanning electron microscope, it would be very interesting to see what the nanoporous papers look like in an SEM.

I looked for information on the details of both nanoporous and swellable coatings, but I didn't find any detailed "how is it made/how does it work" technical references. Does anyone know of any links to such information?

Classic Pearl - 240 GSM swellable satin finish suitable only for dye based inks (slow drying)

Smooth Pearl - 290 GSM nanoporous satin finish suitable for dye and pigmented inks (instant dry)

Smooth Gloss - 280 GSM nanoporous glossy finish suitable for dye and pigmented inks (instant dry)

This image shows the Smooth Gloss paper, with the printable surface on the top and a segment of an edge view on the bottom. The printable surface is on the left of the bottom image - there is a similar coating on the uncoated side, but it was out of focus on this image. Since the paper is about 10 mils (250 microns) thick, it gives a good reference for the scale of the images. The term "nanoporous" implies that there should be small holes in the surface for ink to wick into the paper, and there appear to be multiple (approximately 10 micron diameter) holes in the surface. It was very difficult to focus on the holes, as the holes don't appear to be well defined. The holes appeared sharper when viewed through the stereo eyepieces, but since this image is from only one source it is not as sharp. It was also interesting that the holes were not nearly as visible at higher magnifications, apparently because the depth of field at those magnifications was too short to pick up the poorly defined holes. Note that the contrast has been greatly increased on these images to bring out the details of the holes - they are not nearly as obvious in the microscope or on the original. For another comparison, this post (http://www.nifty-stuff.com/forum/viewtopic.php?id=392) shows the ink dots after they spread out on the paper at almost the same magnification.

This image shows the Smooth Pearl paper. It has similar holes in the surface, and also an irregular (larger scale) surface pattern that gives the paper its satin finish.

This shows three views of the Classic Pearl paper. The top is a similar view as given for the other two papers. Since it is "swellable", it isnt expected to have holes in the surface, and it doesn't. It shows similar ripples from the satin finish, but there is a lot of small scale surface roughness that was not seen with the Smooth Pearl paper. The middle is an edge view, showing that the thickness of the paper varies due to the satin finish (the printable surface is on the right on this image). By way of an explanation of why the focus is so bad, these papers have very soft coatings, and they don't cut cleanly even with a new razor blade (the usual technique is to freeze them in dry ice or even liquid nitrogen before cutting them). The resulting smeared surface is at varying heights that can't all be in focus at once. The bottom part is a close up (at 4x the magnification of the other shots) of just the swellable coating. The swellable coating appears to be made from at least two main layers, and it appears to have another very thin layer between them.

If anyone has access to a scanning electron microscope, it would be very interesting to see what the nanoporous papers look like in an SEM.

I looked for information on the details of both nanoporous and swellable coatings, but I didn't find any detailed "how is it made/how does it work" technical references. Does anyone know of any links to such information?