martop

Getting Fingers Dirty

Hello again, tis me, martop the unlucky,

I have been refilling my ip4300 carts for about 2 weeks and not a problem, well thought not a problem till last night when some of the print outs had a black smudge on the leading edge of the paper, so I did a light head clean and also cleaned the bottom feeder with the folded paper fed from the top feeder, I did this untill the paper came out clean, so 'thought' it was sorted. a while later we tried printing on card, again fed from the top feeder and it had a black smudge on its leading edge.

I got fed up with canons method of cleaning so pulled the printer down to my bench to see if any ink had messed up anywhere but, besides the sponge strip the runs under the print head being a little inky, everything looked ok. I checked the carts to see if any had a leak, all bone dry, not even a drop around the head seals. Only thing left was the underside of the print head, so I removed it and found the black print head had black ink spread along its sides, it was quite thick, so wiped it off with a buddy and some clenaing fluid, sticks it back in the printer and loads the carts.

The test prints I did where ok but about 3 hours later the back smudge was back, taking the print head out again I could see it was covered with black ink.... Cleaned it up again and put the head back in but this time loaded a new oem 5PGBK cart, left it over night and this morning tested the printing, seems ok with the oem cart.

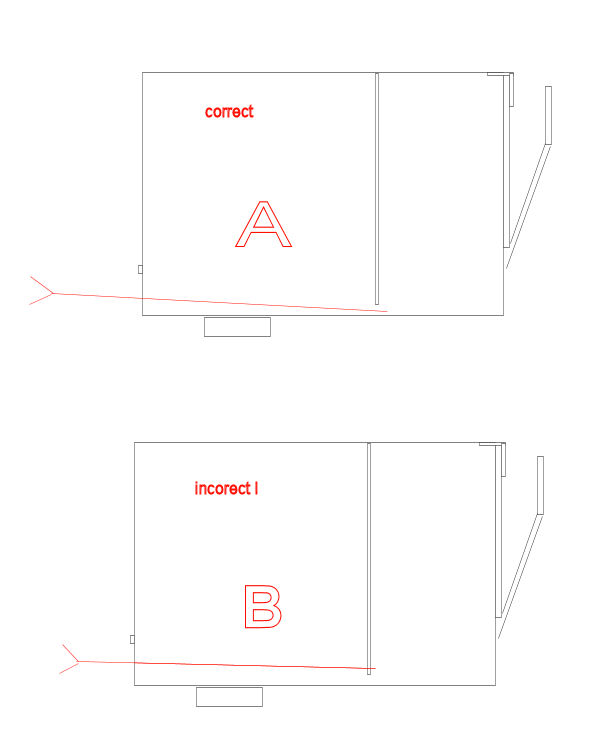

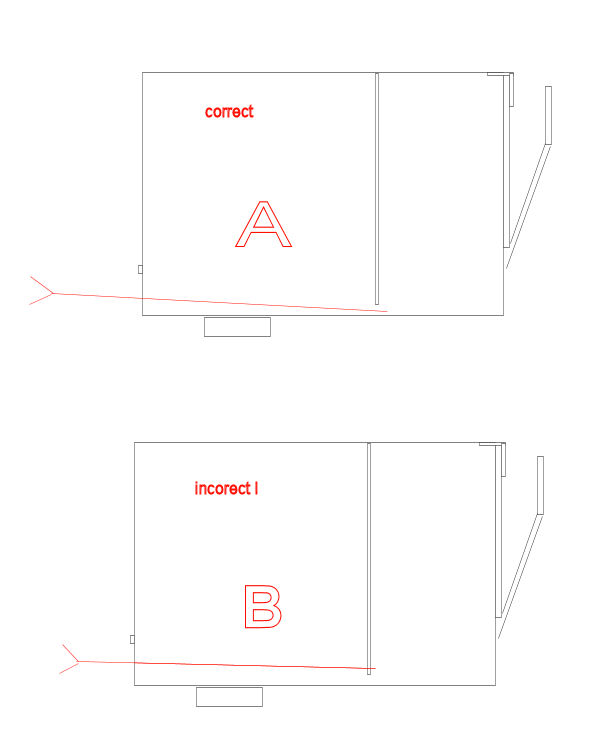

So got to think about this, it seems ( I could be wrong though ) that too much ink was getting through. At the moment I am using the pigment black that came with my redseter from germany so surely that cant be too thin, then gave the refill method some thought, as I cant find any plugs to seal the top fill hole method I opted for the german method, this led me to examine the cart I refilled, after it was emptied and cleaned I noticed the needle had missed the slot at the base of the cart and had gone through the wall a few millimeters higher. A shows how it should be done and B shows what I beleive I have done, using a sharp needle its easy to burst through the ink chamber.

I know this is a long winded post so thanks for bearing with me.. so is it possible by missing the slot and making a small hole with a 22 gauge needle to make the cart feed to much ink ? to me, it seems the feed hole aready in the cart is big enough for a needle to pass through but not big enough to overfeed the ink. I know some cheap inks may mess the heads as well as a leaking cart but this cart is well sealed. I even tried pressing the sides of the cart to expell about 5 drops of ink, not easy as it seemed reluctant to part with any ink.

If making a hole in the wrong place has messed the cart I may seal the holes in the other ones with melted polypropelene and use the top fill method but will have to wait till I get those plugs from hobbicolours as the ones I have came from a refill kit and do not make a seal and dont fancy using a glue gun.

Next question, is it normal for the black print head to have some ink on its underside and can anything else cause the black ink to smear the leading edge of the paper, I hope its not a fault with the printer as sending this back for a repair or service will cost half the price as a new one in postage alone !

martop

I have been refilling my ip4300 carts for about 2 weeks and not a problem, well thought not a problem till last night when some of the print outs had a black smudge on the leading edge of the paper, so I did a light head clean and also cleaned the bottom feeder with the folded paper fed from the top feeder, I did this untill the paper came out clean, so 'thought' it was sorted. a while later we tried printing on card, again fed from the top feeder and it had a black smudge on its leading edge.

I got fed up with canons method of cleaning so pulled the printer down to my bench to see if any ink had messed up anywhere but, besides the sponge strip the runs under the print head being a little inky, everything looked ok. I checked the carts to see if any had a leak, all bone dry, not even a drop around the head seals. Only thing left was the underside of the print head, so I removed it and found the black print head had black ink spread along its sides, it was quite thick, so wiped it off with a buddy and some clenaing fluid, sticks it back in the printer and loads the carts.

The test prints I did where ok but about 3 hours later the back smudge was back, taking the print head out again I could see it was covered with black ink.... Cleaned it up again and put the head back in but this time loaded a new oem 5PGBK cart, left it over night and this morning tested the printing, seems ok with the oem cart.

So got to think about this, it seems ( I could be wrong though ) that too much ink was getting through. At the moment I am using the pigment black that came with my redseter from germany so surely that cant be too thin, then gave the refill method some thought, as I cant find any plugs to seal the top fill hole method I opted for the german method, this led me to examine the cart I refilled, after it was emptied and cleaned I noticed the needle had missed the slot at the base of the cart and had gone through the wall a few millimeters higher. A shows how it should be done and B shows what I beleive I have done, using a sharp needle its easy to burst through the ink chamber.

I know this is a long winded post so thanks for bearing with me.. so is it possible by missing the slot and making a small hole with a 22 gauge needle to make the cart feed to much ink ? to me, it seems the feed hole aready in the cart is big enough for a needle to pass through but not big enough to overfeed the ink. I know some cheap inks may mess the heads as well as a leaking cart but this cart is well sealed. I even tried pressing the sides of the cart to expell about 5 drops of ink, not easy as it seemed reluctant to part with any ink.

If making a hole in the wrong place has messed the cart I may seal the holes in the other ones with melted polypropelene and use the top fill method but will have to wait till I get those plugs from hobbicolours as the ones I have came from a refill kit and do not make a seal and dont fancy using a glue gun.

Next question, is it normal for the black print head to have some ink on its underside and can anything else cause the black ink to smear the leading edge of the paper, I hope its not a fault with the printer as sending this back for a repair or service will cost half the price as a new one in postage alone !

martop