I am truly intrigued and dug further into my cartridge I think I am wrong about the orange area and in fact the main yellow area is the issue. The concerns with the filter remain.

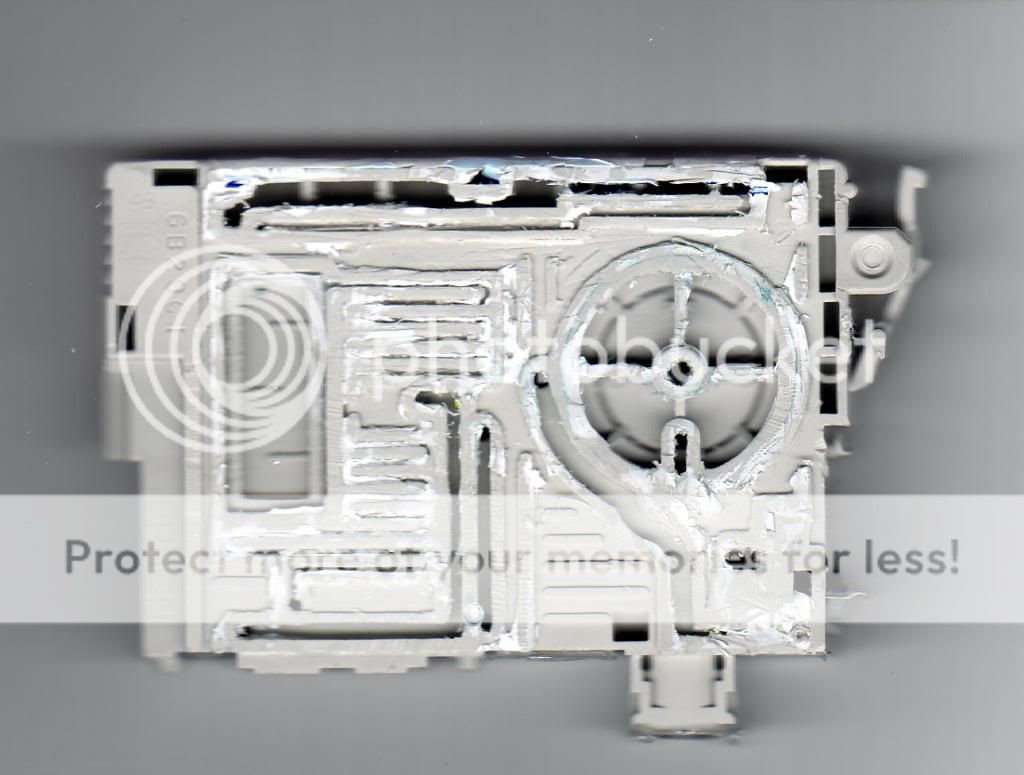

The cartridge on the other side

There are approx 9-12 holes on this side that leads back to the other side! This is not a straightforward design.

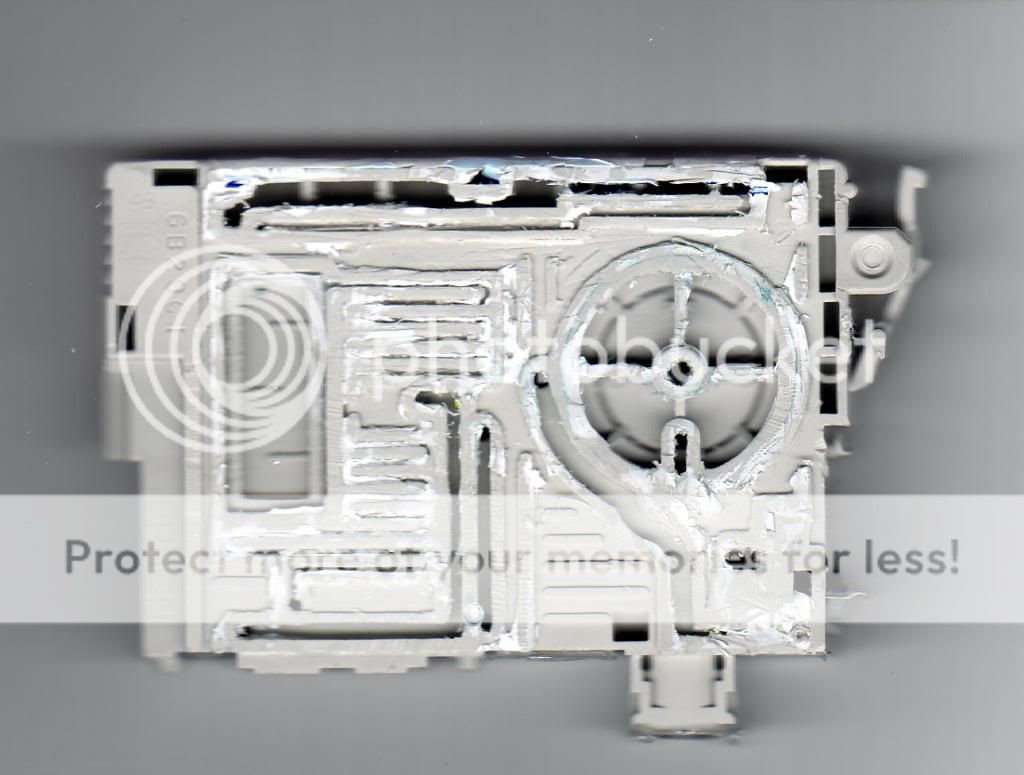

The cartridge on the other side

There are approx 9-12 holes on this side that leads back to the other side! This is not a straightforward design.