Subarub4

Getting Fingers Dirty

I have a crazy question any need for a syringe for a refill? what happens if you just fill the ink side on a flushed cart?

I do own a vacuum pump but I was just curious, the ink I ordered has a tip that allows you to pour from the bottle.

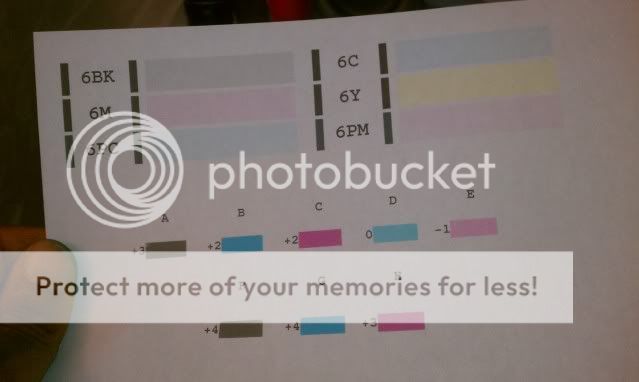

I was reading this here about sealing the carts

http://www.nifty-stuff.com/sealing_canon_bci6.php#more-3

those screws in that size and being nylon might be a little hard to find, in a pinch can I use a glue gun?

I do own a vacuum pump but I was just curious, the ink I ordered has a tip that allows you to pour from the bottle.

I was reading this here about sealing the carts

http://www.nifty-stuff.com/sealing_canon_bci6.php#more-3

those screws in that size and being nylon might be a little hard to find, in a pinch can I use a glue gun?