- Thread starter

- #11

eppyson

Getting Fingers Dirty

- Joined

- Dec 9, 2019

- Messages

- 22

- Reaction score

- 10

- Points

- 33

- Printer Model

- Epson WF-7710

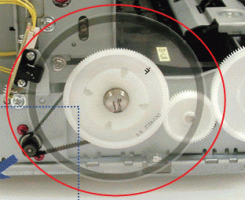

Thanks. I posted images showing the vertical head alignment pattern before and after the trouble started. The second image shows exactly how the last 20 prints look. Nothing I do makes any change, including changing numbers using the alignment program. They seem stuck in the position shown on my second image.Try cleaning the timing wheel on the far left side of the printer..

Also give the timing strip behind the print head another good clean, just to be sure..

P.S. Can you post up a crop of the Pic showing the problem...

How can I clean the timing strip without doing damage to it? Simple kleenex OK? Any liquid?

Could you help me identify which is the timing wheel?