ThrillaMozilla

Printer Master

- Joined

- Jan 18, 2011

- Messages

- 1,242

- Reaction score

- 369

- Points

- 253

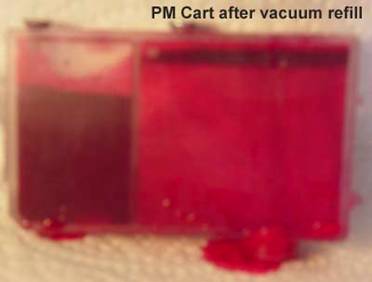

By the way, if you want to get fancy and do this right, pull the vacuum into a chamber (ink supply chamber) that's loaded with ink. Then close valves and let the foam subside. Then vent the chamber slowly and fill about 25% (or maybe 50%?). Finally, open the sponge chamber vent, and open the supply chamber slowly to finish filling the ink chamber. Probably too fancy. Maybe OK if you're filling professionally. Be my guest, gentlemen.