I've run the flex TPU. Had to lower the bed temp (don't remember the temp and am on the road at the moment). Only other challenge has been stringing. Changing extrusion temp and retraction helped, but surfaces when printing at even 0.1 are far from smooth. I've been working with the flex to make mold masters for plaster of paris slip casting molds. Still very much a work in progress. Oh, also had to significantly increase the pressure on the feed wheel, there is a real tendency to stop pushing the filament through...So I forgot..

I have no whip. Do you think printing it with flex TPU be OK.? It's an elastic filament but tough enough for punishing purposes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm A Convert! PEI Heated Spring Steel Bed Plate Surface

- Thread starter Nifty

- Start date

Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,406

- Reaction score

- 1,778

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150, Pro10s,,Voron2.4

Your experiences with TPU seem to match mine. Esun's TPU95 give me good results in general ( no clogs, jams or overal failures) but all perimeters with overhangs look rough, no matter the nozzle temp. or the retractions. Stringing is noticeable but not that bad, although that depends a lot on the geometry of the model. I use 220C for the first layer and 210C for the others; that relatively low temp. keeps stringing under control.

Supports would be a solution for having better overhangs, but trouble is that afterwards it's very difficult to remove those supports without damaging the external finish of the print. A typical case of the remedy being worse than the disease.

Now, if one distant day, I can afford a printer with dual extruder, I could use soluble supports.

Well, dreaming is free..

Supports would be a solution for having better overhangs, but trouble is that afterwards it's very difficult to remove those supports without damaging the external finish of the print. A typical case of the remedy being worse than the disease.

Now, if one distant day, I can afford a printer with dual extruder, I could use soluble supports.

Well, dreaming is free..

I had read advice against supports, but tried them once, and only once! They were impossible to remove without damage. Given that it was a test print, I was fine with tossing it in the trash.it's very difficult to remove those supports without damaging the external finish of the print. A typical case of the remedy being worse than the disease.

- Joined

- Jan 18, 2010

- Messages

- 16,149

- Reaction score

- 9,104

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Now have 3 Ender-3 V3 Plus SE/

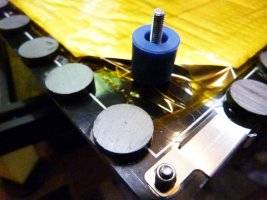

I am about to fit a new PEI steel sheet to my CR-10s, so I have pulled the bed off and am now adding Silicone solid spacer to the bed instead of the usual springs, I am also going to add magnets to the underside of the bed instead of using a full magnetic adhesive sheet. That’s why I removed the bed.

I am still waiting on the PEI sheet to arrive in the post, so I wanted to be ready to print once it gets here, I will update this thread on my progress.

But in the mean time I have a few other bits to print for house management and decided not to wait and crank up my other CR-10 which has been stopped since last October, because I didn’t have enough work for both printers.

I gave the bed a quick clean and a spray of 3Dlac and started her up, she needed a bit of help from my heat gun to get the head and bed up to 10c before I could click on print but it still take 12 minutes to finally warm up and start. Shed temp, was only 8c..

I have printed another few bits on her since and she is working away like it had never been idle at all, these printers still amaze me how well they perform with little or no attention paid to them..

More Pics to come on the PEI steel sheet upgrade for the other CR-10s..

I am still waiting on the PEI sheet to arrive in the post, so I wanted to be ready to print once it gets here, I will update this thread on my progress.

But in the mean time I have a few other bits to print for house management and decided not to wait and crank up my other CR-10 which has been stopped since last October, because I didn’t have enough work for both printers.

I gave the bed a quick clean and a spray of 3Dlac and started her up, she needed a bit of help from my heat gun to get the head and bed up to 10c before I could click on print but it still take 12 minutes to finally warm up and start. Shed temp, was only 8c..

I have printed another few bits on her since and she is working away like it had never been idle at all, these printers still amaze me how well they perform with little or no attention paid to them..

More Pics to come on the PEI steel sheet upgrade for the other CR-10s..

Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,406

- Reaction score

- 1,778

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150, Pro10s,,Voron2.4

So, no monthly maintenance routines lubing the rods and bearings, wiping the dust from fans, checking the electrical connectors, cleaning filament residues from the extruder gears.. . etc, etc.. ?.. How careless of you  .

.

I do likewise.

I do likewise.

- Joined

- Jan 18, 2010

- Messages

- 16,149

- Reaction score

- 9,104

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Now have 3 Ender-3 V3 Plus SE/

Redbrickman

Printer Master

- Joined

- Dec 27, 2010

- Messages

- 1,230

- Reaction score

- 1,375

- Points

- 293

- Location

- UK

- Printer Model

- Brother MFC-L8690-CDW

I hope it works out using the magnets. The magnetic sheet is a uniform magnetic surface so it grips across the entire area whereas the magnets do no produce a uniform "pull" If you use lots of them liek on a Prusa for example then it will probably work, but you will only find out if you print a large print. You are at an advantage with the CR10 if it does not have a bed levelling probe because settting one of those up with magnets is a time consuming task.

- Joined

- Jan 18, 2010

- Messages

- 16,149

- Reaction score

- 9,104

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Now have 3 Ender-3 V3 Plus SE/

I won’t be able to test out my idea just yet, because the PEI plate is still in the post and will be for another 7-10 days yet, but as you can see the magnets on the edges of the hot bed should be as good as any adhesive sheet.The magnetic sheet is a uniform magnetic surface so it grips across the entire area whereas the magnets do no produce a uniform "

If not it’s back to square one..

click to enlarge..

click to enlarge..Redbrickman

Printer Master

- Joined

- Dec 27, 2010

- Messages

- 1,230

- Reaction score

- 1,375

- Points

- 293

- Location

- UK

- Printer Model

- Brother MFC-L8690-CDW

I'm confused looking at the photo. If you fit the bed on those spacers surely the distance is too great for the magnets to work?

- Joined

- Jan 18, 2010

- Messages

- 16,149

- Reaction score

- 9,104

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Now have 3 Ender-3 V3 Plus SE/

No that’s not the case. You are in fact looking at the underside of the hot bed itself, and the yellow foil sheet is the insulation of the heater coil, does that make sense..I'm confused looking at the photo.

These magnets have a pull distance (Attraction) of about 25 mm..

Latest posts

-

-

-

Picture Of The Week (POW) Information and Submissions

- Latest: PK Project Manager

-