Redbrickman

Printer Master

- Joined

- Dec 27, 2010

- Messages

- 1,230

- Reaction score

- 1,375

- Points

- 293

- Location

- UK

- Printer Model

- Brother MFC-L8690-CDW

Ah Ok it was the spacers that confused me

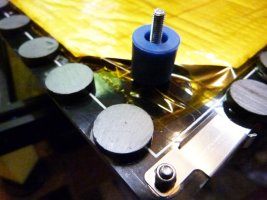

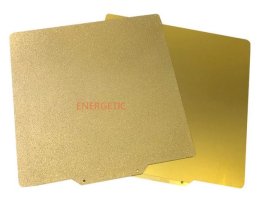

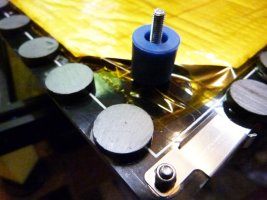

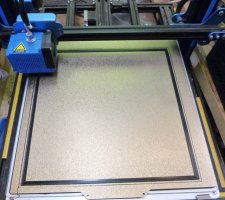

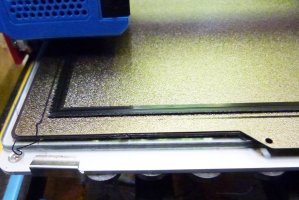

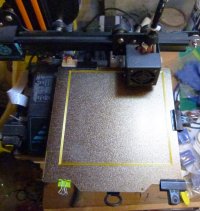

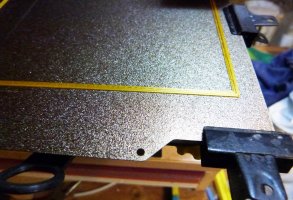

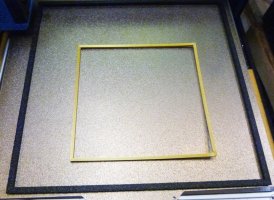

Once the magnetic sheet and PEI metal sheet arrive, I'll be curious for you to test the attraction difference between using the magnet config you have vs. the magnetic sheet. Keep us posted!I won’t be able to test out my idea just yet, because the PEI plate is still in the post and will be for another 7-10 days yet, but as you can see the magnets on the edges of the hot bed should be as good as any adhesive sheet.

If not it’s back to square one..

View attachment 13856 View attachment 13857 click to enlarge..

I’m not just doing this for adventure, my idea was to get away from the adhesive magnetic sheet, I’m always up for trying something different, and besides I was never a fan of these magnetic sheets, that’s why I’ve kept the other printer with the glass plate..Keep us posted!

That sounds like a good idea,First, return it to Amazon - they will take it back and refund you.

and I may get a new board from the AliExpress link you provided too..

https://www.aliexpress.com/item/400...1;23.38;-1;-1@salePrice;GBP;search-mainSearchOnce the magnetic sheet and PEI metal sheet arrive, I'll be curious for you to test the attraction difference between using the magnet config you have vs. the magnetic sheet. Keep us posted!

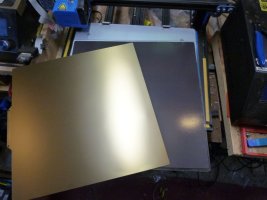

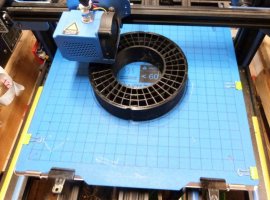

like this one on the other CR-10

like this one on the other CR-10This is good to know. I upgraded to the yellow springs, and they do seem better than OEM... then the silicone became the "cool better thing" and I was wondering if I should have done those instead. Now I'm even more confident that the yellow springs are just fine. If it ain't broke.... right @The Hat ?I wasn’t very happy with them at all, and I reckon they also expand a little during use from the heat of the hot bad, so it’s out with the new and back to the old springs, and my verdict on them is I didn’t find them very versatile and not worth the trouble using.

I was thinking about doing similar with mine, but decided to just put it on the main bed.So I was forced to use the self-adhesive magnetic sheet, but wait for it.. Because this is the best bit, so instead of applying it to the hotbed I stuck it to the Feckin original glass plate that came with the printer.

Sorry you've had problems with it. I've been surprisingly happy with it since:The object of these PEI sheets are that they make it easier to remove a finished print, but if the print is lifting before its complete then the PEI sheet has failed, I made some 10 test prints between the two printers and 95% of them lifted.. (over 8 hours)