Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,406

- Reaction score

- 1,778

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150, Pro10s,,Voron2.4

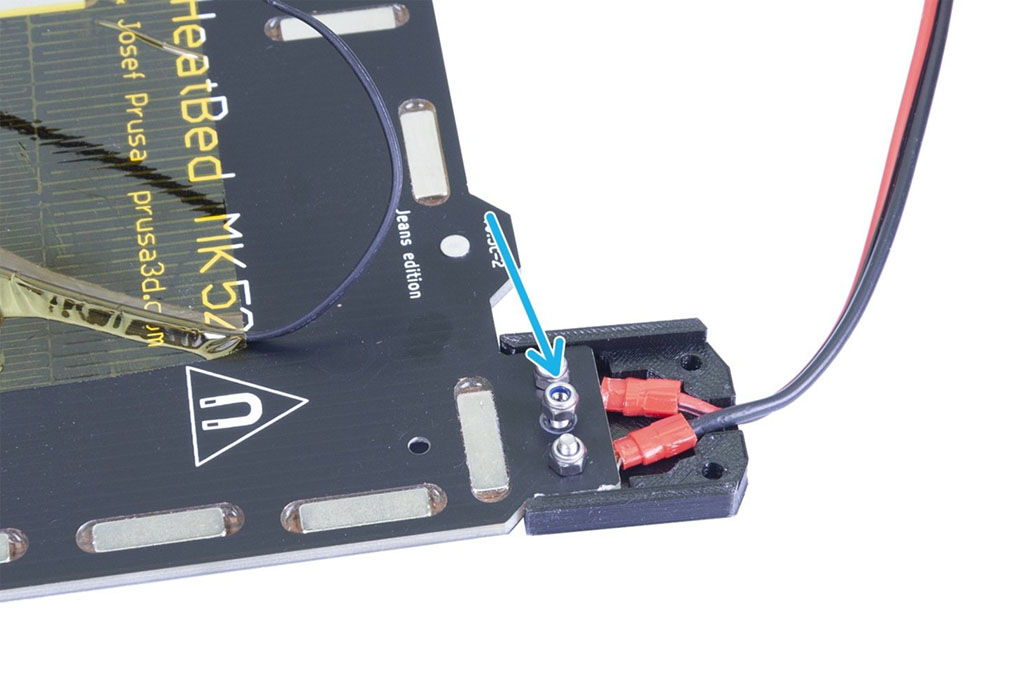

Below you see a part of the hotbed's bottom. The rectangular magnets are glued all around the perimeter ( and also in the center). Being embedded in lozenge shaped gaps of the bed, they're flush with the surface. The glue fills totally the hole.

If you had to glue them on a flat surface, the magnets would stick out and would be far more difficult to keep them attached.

If you had to glue them on a flat surface, the magnets would stick out and would be far more difficult to keep them attached.