- Joined

- Dec 27, 2014

- Messages

- 6,355

- Reaction score

- 7,572

- Points

- 373

- Location

- Germany

- Printer Model

- L805, WF2010, ET8550, T3100X

I think I got astray when looking for printhead refurbishing - I would need some equipment I don't have

Spot Welder

Introduction

This is a very useful machine for the printer head repair...................

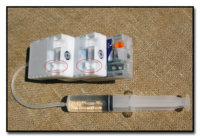

You may try to do some airbrushing with the printhead and your compressor.

Spot Welder

Introduction

This is a very useful machine for the printer head repair...................

You may try to do some airbrushing with the printhead and your compressor.