ConradH

Printing Apprentice

- Joined

- Oct 7, 2025

- Messages

- 11

- Reaction score

- 8

- Points

- 13

- Printer Model

- Canon PRO-100

Perhaps I should start a new thread, but I wanted to put up some test results on my CM30. It's obviously a CM30 by color and function but nowhere does that label appear. It's a $79 Veykolor Pro from Amazon- I didn't want to mess with overseas sellers.

Know several things. I'm an idiot. A fairly sophisticated one, but I make mistakes and often slide a foot back for every 13" I move forward. I have a mash-up of software and have not worked through to actually profile with the CM30, just comparisons to get a feel for the thing.

OK, so I have an ancient eye-one UVcut and ProfileMaker 5.0. It does have the matching cal base. I also have the Babel programs and the PC app for the CM30. I was fortunate enough to be gifted a set of Labsphere reflectivity targets by a friend who left the color business, though the certs are long gone. They should still be decent.

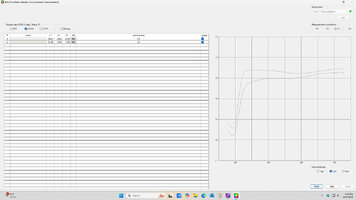

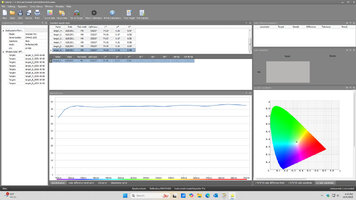

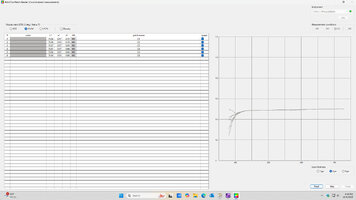

The first thing that seemed interesting was to compare the CM30 and the eye-one using paper with more and less optical brightening agents. Using my Harbor Freight UV flashlight and a Red River sample pack, I found two likely candidates, UltraPro Gloss (very white) and Premium Gloss C2S (ever so slightly yellow). This image is from the eye-one and since it's UV filtered the difference between the papers isn't huge, though far from zero.

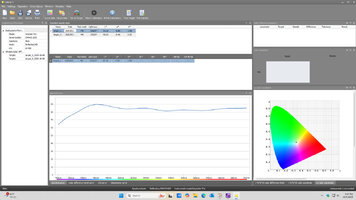

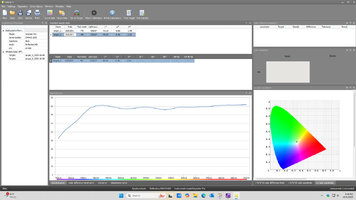

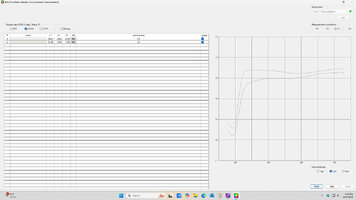

The CM30 software only shows one graph at a time, so here are two images.

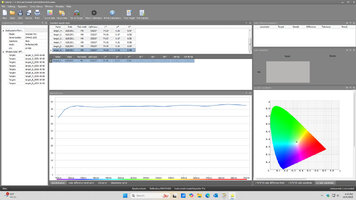

You can see the drop at the short wavelength end is substantial with less optical brighteners.

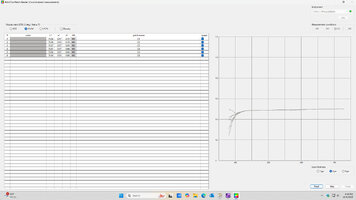

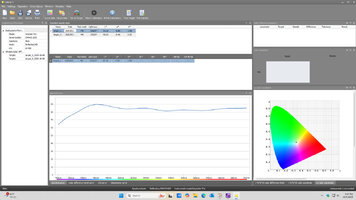

That tells me that to compare the two spectrophotometers I need to use a spectrally flat target, like the Labsphere ones, with no brighteners. (That's not got much Spam in it. What do you mean, you don't want any Spam!) I used the 50% reflectivity one, which I think should have an L of 76.

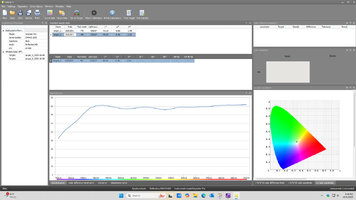

I don't know why the eye-one varies as much as it does at the 400 end. Here's the CM30.

To save your eyesight, the Lab values are 75.57, 0.17 and 0.66 for the eye-one. Then 74.28, 0.15 and 0.59 for the CM30. Both were set to D50/2deg. I think that's a delta E of less than 1.

Hopefully this was of at least some interest to somebody and certainly do point out whatever blunders I've made.

CH

Know several things. I'm an idiot. A fairly sophisticated one, but I make mistakes and often slide a foot back for every 13" I move forward. I have a mash-up of software and have not worked through to actually profile with the CM30, just comparisons to get a feel for the thing.

OK, so I have an ancient eye-one UVcut and ProfileMaker 5.0. It does have the matching cal base. I also have the Babel programs and the PC app for the CM30. I was fortunate enough to be gifted a set of Labsphere reflectivity targets by a friend who left the color business, though the certs are long gone. They should still be decent.

The first thing that seemed interesting was to compare the CM30 and the eye-one using paper with more and less optical brightening agents. Using my Harbor Freight UV flashlight and a Red River sample pack, I found two likely candidates, UltraPro Gloss (very white) and Premium Gloss C2S (ever so slightly yellow). This image is from the eye-one and since it's UV filtered the difference between the papers isn't huge, though far from zero.

The CM30 software only shows one graph at a time, so here are two images.

You can see the drop at the short wavelength end is substantial with less optical brighteners.

That tells me that to compare the two spectrophotometers I need to use a spectrally flat target, like the Labsphere ones, with no brighteners. (That's not got much Spam in it. What do you mean, you don't want any Spam!) I used the 50% reflectivity one, which I think should have an L of 76.

I don't know why the eye-one varies as much as it does at the 400 end. Here's the CM30.

To save your eyesight, the Lab values are 75.57, 0.17 and 0.66 for the eye-one. Then 74.28, 0.15 and 0.59 for the CM30. Both were set to D50/2deg. I think that's a delta E of less than 1.

Hopefully this was of at least some interest to somebody and certainly do point out whatever blunders I've made.

CH

Last edited:

Anyway, I suspect reading and writing to the CR30 (which I often type wrong as CM30 and various other things) will be beyond my skills. I plugged in the USB, which looks like serial COM5 on my machine, and did a single read of an orange card while a sniffer program was running. Here's what was sent and received, and I'm not sure how to make any sense of it.

Anyway, I suspect reading and writing to the CR30 (which I often type wrong as CM30 and various other things) will be beyond my skills. I plugged in the USB, which looks like serial COM5 on my machine, and did a single read of an orange card while a sniffer program was running. Here's what was sent and received, and I'm not sure how to make any sense of it.