joseph1949

Getting Fingers Dirty

Why did I have a bad nozzle test? Heads up for people who store carts.

To: all

Here are my specs:

1. Two- Canon PIXMA MX870 printers

2. Each printer uses four-CLI-221carts and one-PGI-220BK cart. All five carts have transparent ink reservoirs.

3. I use the top fill method to fill the carts.

4. I use hot glue as the plug material. I use my coin/paper disc method to create the hot glue plug.

5. I use InkTec inks.

Quick read: I had a bad nozzle test on a used unfilled PGI-220BK cart that I removed from my refrigerator and filled. The kicker is that the first four nozzle tests were good. The fifth nozzle test showed up bad!!!!!!

Back story: how I store my carts.

I store my carts in my refrigerator. This is where I store my InkTec ink (one liter containers), also. I store three types of carts: unused OEM carts, OEM carts and Carboodle carts (OEM Canon carts with Carboodle ink) that have been used (cart removed from printer when ink reservoir is empty), and carts that I have previously used, filled, place in printer, use-up the ink, and then place in refrig.

Note: I do not fill carts for future usewhich means that there are no filled carts for future use in my refrig.

Back story: Why I changed out my filling carts.

I had a number of unused older OEM carts in the frig that I wanted to use-up before their pass due date was up. So I replaced my regular filling carts with the unused older OEM carts. After I ran out of the older OEM carts I decided to replace the older carts with used unfilled carts. I did not want to use the regular filling carts because I wanted to see if there would be any problems filling/using the used unfilled carts. Most of these carts are over 12+ months old. I was hoping that I would have no problems in using the carts. My hopes were not realized.

When a place a used cart in my frig I cover the air vent with tape and I cover the ink outlet with an orange cap (with rubber bands). After this I place the cart in a plastic baggie. I place a piece of paper towel soaked with isopropyl alcohol in a separate plastic baggie. I then place the plastic baggie with the cart inside the baggie with the soaked piece of paper towel. I do this to keep the isopropyl alcohol from direct contact with the cart. I believe if the alcohol comes in contact with the cart over time the alcohol will do bad things to the carts seal, the tape over the air vent, top fill plug, and the rubber bands. The purpose of using the alcohol is to keep down the mold and whatnot. Note: If the cart has a top fill hole plug I keep the plug intact.

Over a period of five days I removed four carts from my printer. The first day I removed a PGI-220Bk cart with a used unfilled OEM cart and replaced a CLI-221M with a used unfilled OEM cart. I created a top fill hole on each cart and filled the ink reservoir on each cart. I placed each cart in the printer. I waited until the next morning to do a nozzle test. I performed the nozzle test and it was a good test.

Note: I remove a cart when the ink reservoir is just empty or almost empty.

Over the next three days I replaced a CLI-221C cart and a CLI-221Y cart with used unfilled carts. I filled the carts. I performed a nozzle test (next morning) on the C cart. The nozzle test showed no problems. The next day I performed a nozzle test on the Y cart. To my surprise the nozzle test showed that the PGI-220BK cart had a problem. The M, C, Y, and the BK carts were all good. Note: The BK cart is still an older OEM cart.

Note: Please see below for pictures of the nozzle tests.

I did two cleanings and FOUR DEEP CLEANINGS to unclog the PGI-220BK cart.

QUESTION: Why did the PGI cart show a good nozzle test after it was first placed in the printer, but on the fifth day the fifth nozzle test showed up bad for the PGI cart?

Good things to know: I made no prints during the five day period. The tag on the PGI cart showed that I removed the cart from the printer on 8/8/11. After I removed the cart I placed the cart in the frig. If you go back in time the cart was probably in the printer for no more than two months. I bought my last pack of carts sometime in early 2011. Let us say that the cart has been in my procession for 18 months.

My thoughts on why the PGI cart had a bad nozzle test and why the CLI carts had good nozzle tests (well, up to nowknock on wood!!!!!):

1. PGI ink is pigment ink. Based on my experience with the pigment ink the ink has a high solids content. I believe that the high solids content if not THE reason for the clogging of the PGI cart then the solids is at the top of list of reasons why the PGI cart clogged.

2. The overall age of the cart.

3. The time the cart was in the frig. This would be 12 months (8/8/11-8/7/12).

4. The CLI carts use dye ink. Dye ink has a very low solids content if any. The CLI carts are about the same age as the PGI cart and they have been in the frig for about the same about of time. The CLI carts show good nozzle tests.

Conclusion: The main reason why the PGI become clogged was because of its high solids content. A close second reason is the time the PGI spent in the frig. If you do not use a PGI cart for an extended period of time you will have a good chance that the cart will clog. What to do? Rotate your PGI carts and it wouldnt hurt to rotate your CLI carts.

Note: Since the PGI was my first clogged cart I can say that the InkTec ink contributed very little if anything to the clogging of the PGI cart.

What have we learned from my bad nozzle tests:

1. Having a bad nozzle test is not the end of the world. I decided to perform a cleaning and see what happens. My cleanings showed some progress. I decided to do a deep cleaning. It took four deep cleanings, but they unclogged the cart. Cleanings and deep cleanings are a lot less of a hassle than flushing a cart (a PGI-220BK cart) or flushing a print head (by a factor of a thousand!!!!!!).

2. Rotate the carts that you store. I would keep a used filled PGI-220BK cart in the printer no longer than for one month. I would keep a used filled CLI cart in the printer no longer than two or three months. Experience with the carts may enable you to keeps the carts in the printer longeryour call. It would be smart to tag each cart so to keep up with what cart should be the next one inline to be placed in the printer.

3. Shake-up your bulk ink containers before you place the ink in your squeeze bottle or syringe. This goes double for the PGI-220BK bulk ink container. When I remove a bulk ink container from my frig I place the container upside down in my kitchen sink. The container stays in this position for at least for a half hour (longer for the PGI-220BK container). When the container has been upside down long enough I pick-up the container and I gently shake the container. After shaking the container I pour the ink into my squeeze bottle (2 oz.). You should also shake the squeeze bottle before placing the ink into the cart. Note: All my bulk ink containers are of the one liter size.

4. I suggest you buy your ink in one liter containers. Deep cleanings use-up an ungodly amount of ink. Also, ink is a lot cheaper in one liter containers. You can assume that if you store and rotate your carts you will need to do a lot of deep cleaningsstuff happens.

5. I think it would be a good idea to do a nozzle test once a day if you store and rotate your carts. The nozzle test(s) will give you a quick and easy way to tell if the carts are O.K. The nozzle test uses up very little ink and it can act like a light cleaning.

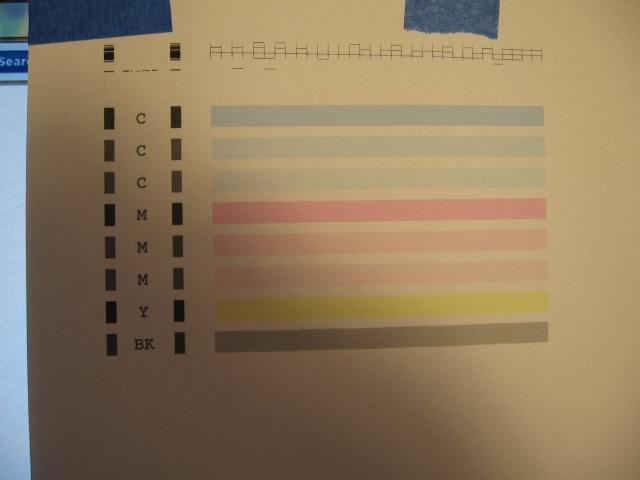

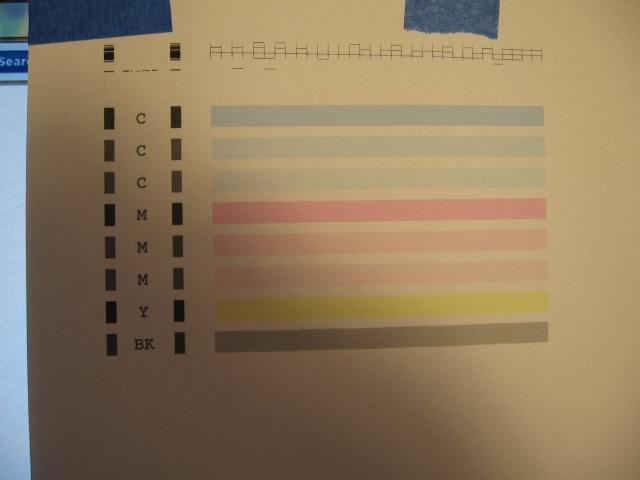

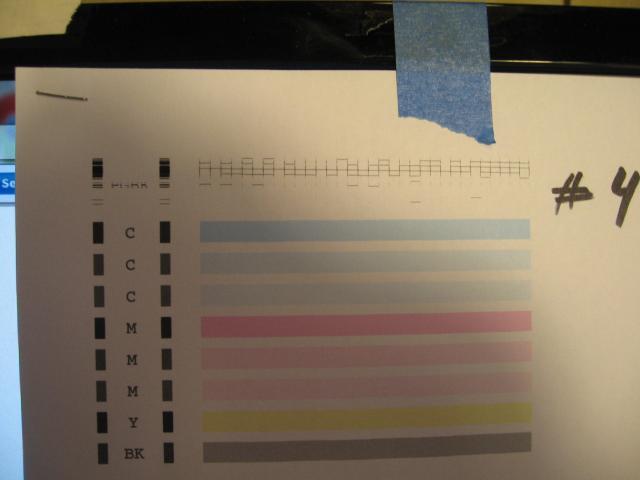

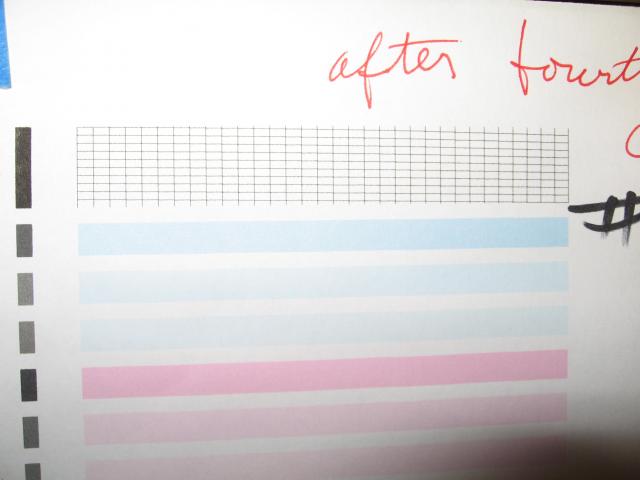

1. This picture shows the bad nozzle test. As you can see the PGBK cart is not O.K. The PGBK cart shows some flow but not much. The CLI carts are O.K. #3048

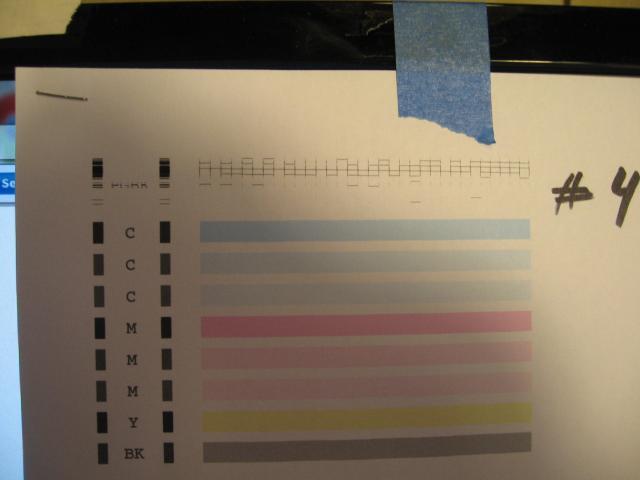

2. This picture shows the nozzle test after two cleanings. There is some improvement but not much. The improvement gives me hope that a deep cleaning can help. #3051

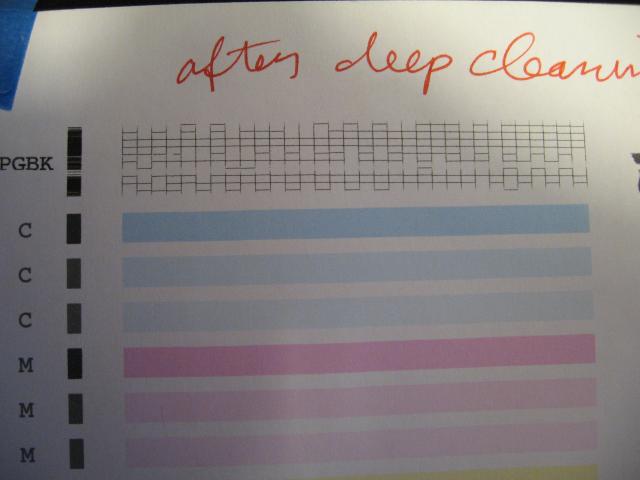

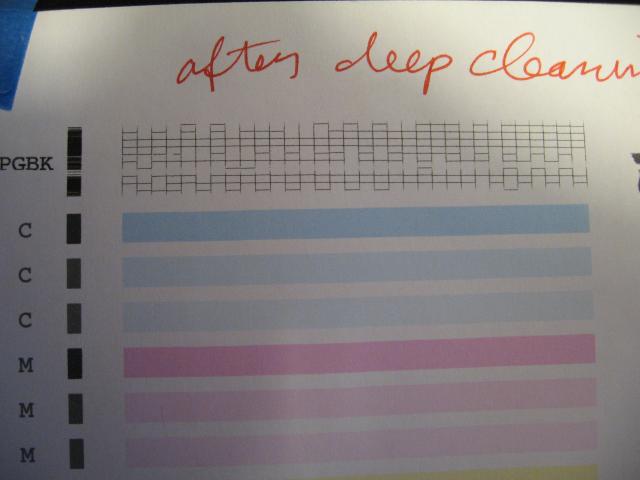

3. This picture shows the nozzle test after one deep cleaning. As you can see there is a marked improvement. I am thinking I can pull this off. Another deep cleaning and I will have an unclogged cart. Another plus is that I will not have to flush a cartsomething I have not done before. #3053

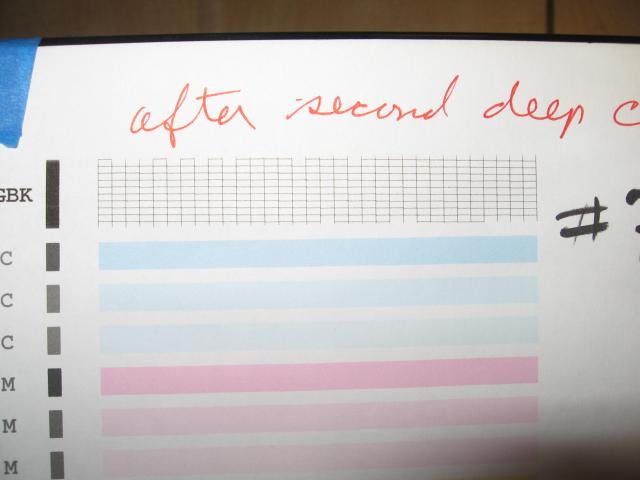

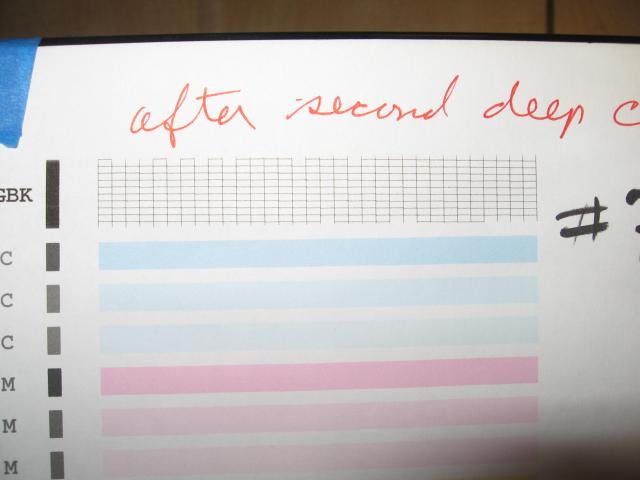

4. This picture shows the nozzle test after the second deep cleaning. We see further improvement, but we still need another deep cleaningdraaaaaaat!!!!!!! #3055

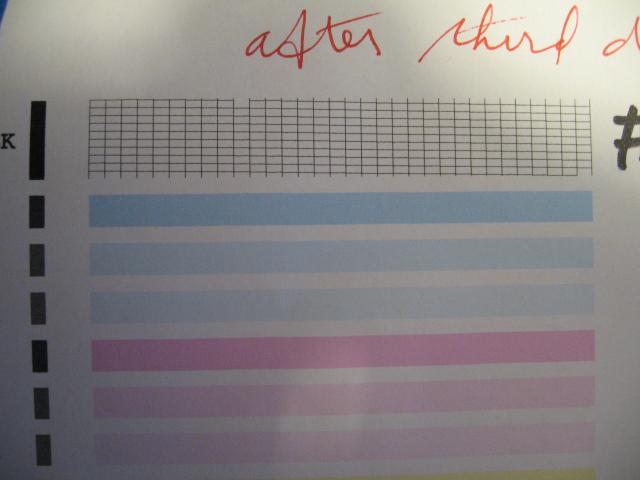

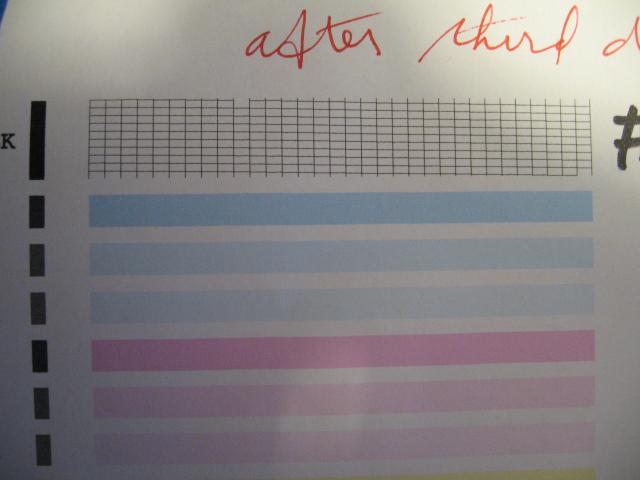

5. This picture shows the nozzle test after the third deep cleaning. Boy, are we close, but no cigar. We need to do another ink-sucking deep cleaning. #3058

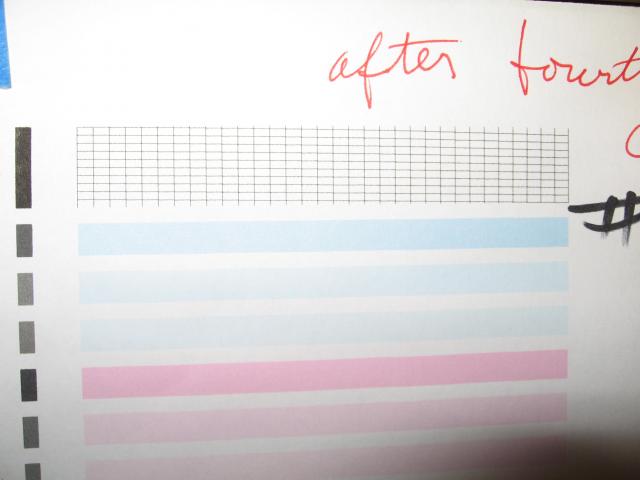

6. This picture shows the nozzle test after the fourth and final deep cleaning. Eureka!!! We have a good nozzle test for the PGI cart. The CLI carts look O.K., too!!!!!!! Note: The printer showed a low ink warning on the PGI-220BK cart. #3060

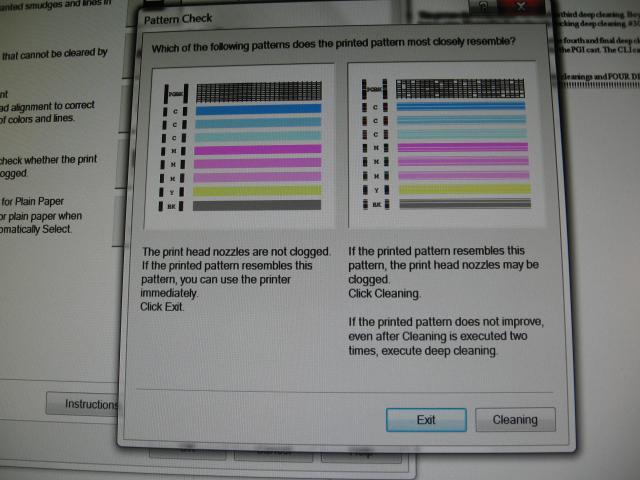

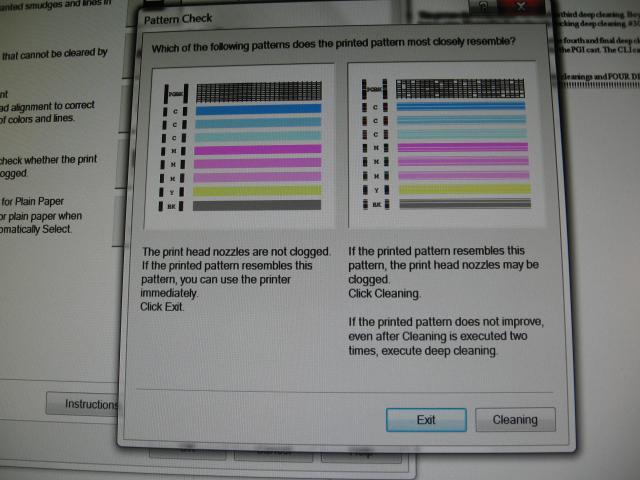

7. This picture is what Canon shows so one can tell the difference between a good nozzle test and a bad nozzle test. The nozzle test on the right is very generic when it comes to showing what clogged carts look like. If you have any doubt if you have a bad cart, contact the people on this site BEFORE YOU DO ANYTHING. #3080

Note: If you have been keeping track it took two cleanings and FOUR DEEP CLEANINGS to unclog the PGBK cart. Yahoo!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

If I get a bad nozzle test because of a clogged CLI cart I will not do any cleanings or deep cleanings. I will remove the offending cart and replace it with a good cart. To do a cleaning/deep cleaning on one CLI you have to do a cleaning/deep cleaning on all four CLI carts at once. You cannot do a cleaning/deep cleaning on an individual cart. What happens is that if the clogged cart takes a lot of deep cleanings to be cleaned then you will be filling all four carts. You could endup filling the carts more than oncenot fun, Zen attitude or not.

I would rather replace the clogged cart with a good cart and flush the clogged cart. This is one instance that flushing a cart is less of a hassle than doing a clean/deep cleaning on a cart.

Thank you.

To: all

Here are my specs:

1. Two- Canon PIXMA MX870 printers

2. Each printer uses four-CLI-221carts and one-PGI-220BK cart. All five carts have transparent ink reservoirs.

3. I use the top fill method to fill the carts.

4. I use hot glue as the plug material. I use my coin/paper disc method to create the hot glue plug.

5. I use InkTec inks.

Quick read: I had a bad nozzle test on a used unfilled PGI-220BK cart that I removed from my refrigerator and filled. The kicker is that the first four nozzle tests were good. The fifth nozzle test showed up bad!!!!!!

Back story: how I store my carts.

I store my carts in my refrigerator. This is where I store my InkTec ink (one liter containers), also. I store three types of carts: unused OEM carts, OEM carts and Carboodle carts (OEM Canon carts with Carboodle ink) that have been used (cart removed from printer when ink reservoir is empty), and carts that I have previously used, filled, place in printer, use-up the ink, and then place in refrig.

Note: I do not fill carts for future usewhich means that there are no filled carts for future use in my refrig.

Back story: Why I changed out my filling carts.

I had a number of unused older OEM carts in the frig that I wanted to use-up before their pass due date was up. So I replaced my regular filling carts with the unused older OEM carts. After I ran out of the older OEM carts I decided to replace the older carts with used unfilled carts. I did not want to use the regular filling carts because I wanted to see if there would be any problems filling/using the used unfilled carts. Most of these carts are over 12+ months old. I was hoping that I would have no problems in using the carts. My hopes were not realized.

When a place a used cart in my frig I cover the air vent with tape and I cover the ink outlet with an orange cap (with rubber bands). After this I place the cart in a plastic baggie. I place a piece of paper towel soaked with isopropyl alcohol in a separate plastic baggie. I then place the plastic baggie with the cart inside the baggie with the soaked piece of paper towel. I do this to keep the isopropyl alcohol from direct contact with the cart. I believe if the alcohol comes in contact with the cart over time the alcohol will do bad things to the carts seal, the tape over the air vent, top fill plug, and the rubber bands. The purpose of using the alcohol is to keep down the mold and whatnot. Note: If the cart has a top fill hole plug I keep the plug intact.

Over a period of five days I removed four carts from my printer. The first day I removed a PGI-220Bk cart with a used unfilled OEM cart and replaced a CLI-221M with a used unfilled OEM cart. I created a top fill hole on each cart and filled the ink reservoir on each cart. I placed each cart in the printer. I waited until the next morning to do a nozzle test. I performed the nozzle test and it was a good test.

Note: I remove a cart when the ink reservoir is just empty or almost empty.

Over the next three days I replaced a CLI-221C cart and a CLI-221Y cart with used unfilled carts. I filled the carts. I performed a nozzle test (next morning) on the C cart. The nozzle test showed no problems. The next day I performed a nozzle test on the Y cart. To my surprise the nozzle test showed that the PGI-220BK cart had a problem. The M, C, Y, and the BK carts were all good. Note: The BK cart is still an older OEM cart.

Note: Please see below for pictures of the nozzle tests.

I did two cleanings and FOUR DEEP CLEANINGS to unclog the PGI-220BK cart.

QUESTION: Why did the PGI cart show a good nozzle test after it was first placed in the printer, but on the fifth day the fifth nozzle test showed up bad for the PGI cart?

Good things to know: I made no prints during the five day period. The tag on the PGI cart showed that I removed the cart from the printer on 8/8/11. After I removed the cart I placed the cart in the frig. If you go back in time the cart was probably in the printer for no more than two months. I bought my last pack of carts sometime in early 2011. Let us say that the cart has been in my procession for 18 months.

My thoughts on why the PGI cart had a bad nozzle test and why the CLI carts had good nozzle tests (well, up to nowknock on wood!!!!!):

1. PGI ink is pigment ink. Based on my experience with the pigment ink the ink has a high solids content. I believe that the high solids content if not THE reason for the clogging of the PGI cart then the solids is at the top of list of reasons why the PGI cart clogged.

2. The overall age of the cart.

3. The time the cart was in the frig. This would be 12 months (8/8/11-8/7/12).

4. The CLI carts use dye ink. Dye ink has a very low solids content if any. The CLI carts are about the same age as the PGI cart and they have been in the frig for about the same about of time. The CLI carts show good nozzle tests.

Conclusion: The main reason why the PGI become clogged was because of its high solids content. A close second reason is the time the PGI spent in the frig. If you do not use a PGI cart for an extended period of time you will have a good chance that the cart will clog. What to do? Rotate your PGI carts and it wouldnt hurt to rotate your CLI carts.

Note: Since the PGI was my first clogged cart I can say that the InkTec ink contributed very little if anything to the clogging of the PGI cart.

What have we learned from my bad nozzle tests:

1. Having a bad nozzle test is not the end of the world. I decided to perform a cleaning and see what happens. My cleanings showed some progress. I decided to do a deep cleaning. It took four deep cleanings, but they unclogged the cart. Cleanings and deep cleanings are a lot less of a hassle than flushing a cart (a PGI-220BK cart) or flushing a print head (by a factor of a thousand!!!!!!).

2. Rotate the carts that you store. I would keep a used filled PGI-220BK cart in the printer no longer than for one month. I would keep a used filled CLI cart in the printer no longer than two or three months. Experience with the carts may enable you to keeps the carts in the printer longeryour call. It would be smart to tag each cart so to keep up with what cart should be the next one inline to be placed in the printer.

3. Shake-up your bulk ink containers before you place the ink in your squeeze bottle or syringe. This goes double for the PGI-220BK bulk ink container. When I remove a bulk ink container from my frig I place the container upside down in my kitchen sink. The container stays in this position for at least for a half hour (longer for the PGI-220BK container). When the container has been upside down long enough I pick-up the container and I gently shake the container. After shaking the container I pour the ink into my squeeze bottle (2 oz.). You should also shake the squeeze bottle before placing the ink into the cart. Note: All my bulk ink containers are of the one liter size.

4. I suggest you buy your ink in one liter containers. Deep cleanings use-up an ungodly amount of ink. Also, ink is a lot cheaper in one liter containers. You can assume that if you store and rotate your carts you will need to do a lot of deep cleaningsstuff happens.

5. I think it would be a good idea to do a nozzle test once a day if you store and rotate your carts. The nozzle test(s) will give you a quick and easy way to tell if the carts are O.K. The nozzle test uses up very little ink and it can act like a light cleaning.

1. This picture shows the bad nozzle test. As you can see the PGBK cart is not O.K. The PGBK cart shows some flow but not much. The CLI carts are O.K. #3048

2. This picture shows the nozzle test after two cleanings. There is some improvement but not much. The improvement gives me hope that a deep cleaning can help. #3051

3. This picture shows the nozzle test after one deep cleaning. As you can see there is a marked improvement. I am thinking I can pull this off. Another deep cleaning and I will have an unclogged cart. Another plus is that I will not have to flush a cartsomething I have not done before. #3053

4. This picture shows the nozzle test after the second deep cleaning. We see further improvement, but we still need another deep cleaningdraaaaaaat!!!!!!! #3055

5. This picture shows the nozzle test after the third deep cleaning. Boy, are we close, but no cigar. We need to do another ink-sucking deep cleaning. #3058

6. This picture shows the nozzle test after the fourth and final deep cleaning. Eureka!!! We have a good nozzle test for the PGI cart. The CLI carts look O.K., too!!!!!!! Note: The printer showed a low ink warning on the PGI-220BK cart. #3060

7. This picture is what Canon shows so one can tell the difference between a good nozzle test and a bad nozzle test. The nozzle test on the right is very generic when it comes to showing what clogged carts look like. If you have any doubt if you have a bad cart, contact the people on this site BEFORE YOU DO ANYTHING. #3080

Note: If you have been keeping track it took two cleanings and FOUR DEEP CLEANINGS to unclog the PGBK cart. Yahoo!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

If I get a bad nozzle test because of a clogged CLI cart I will not do any cleanings or deep cleanings. I will remove the offending cart and replace it with a good cart. To do a cleaning/deep cleaning on one CLI you have to do a cleaning/deep cleaning on all four CLI carts at once. You cannot do a cleaning/deep cleaning on an individual cart. What happens is that if the clogged cart takes a lot of deep cleanings to be cleaned then you will be filling all four carts. You could endup filling the carts more than oncenot fun, Zen attitude or not.

I would rather replace the clogged cart with a good cart and flush the clogged cart. This is one instance that flushing a cart is less of a hassle than doing a clean/deep cleaning on a cart.

Thank you.