Steve J

Getting Fingers Dirty

- Joined

- Feb 8, 2019

- Messages

- 26

- Reaction score

- 29

- Points

- 48

- Printer Model

- Canon Pro1000, Prusa I3MK3

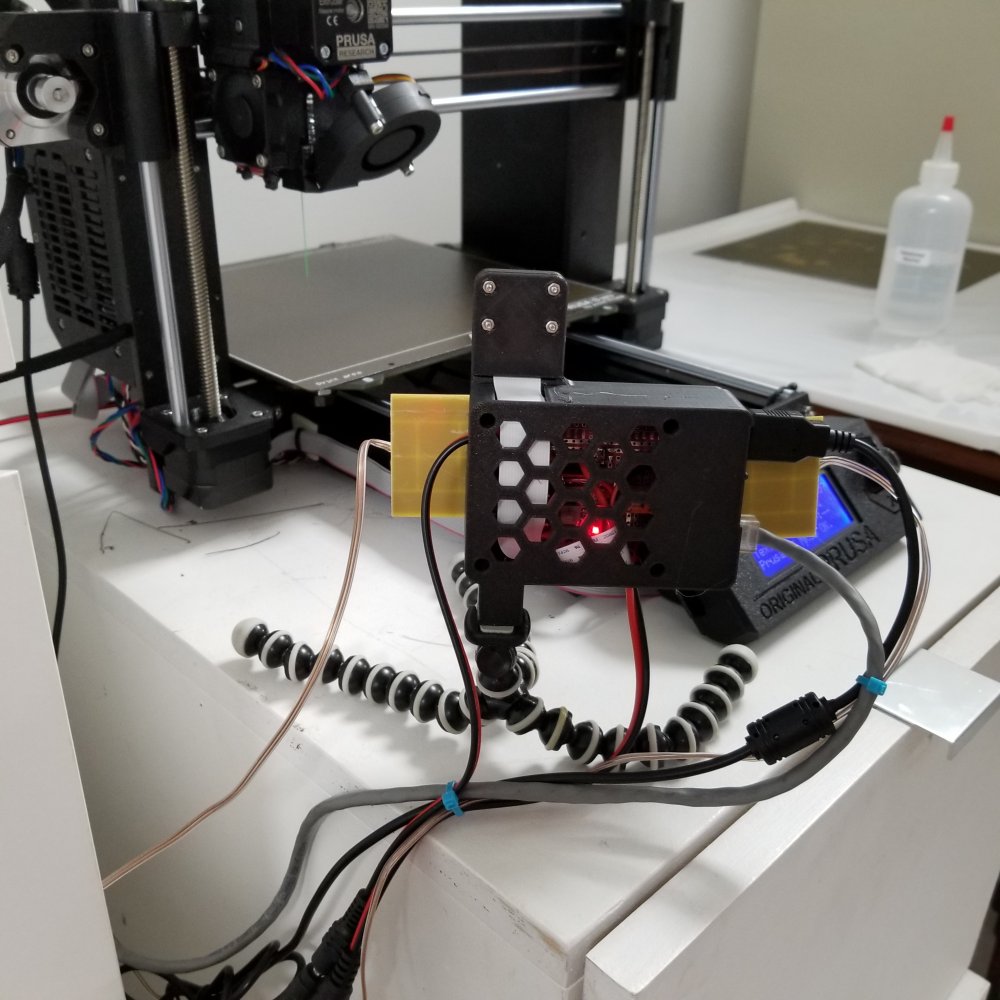

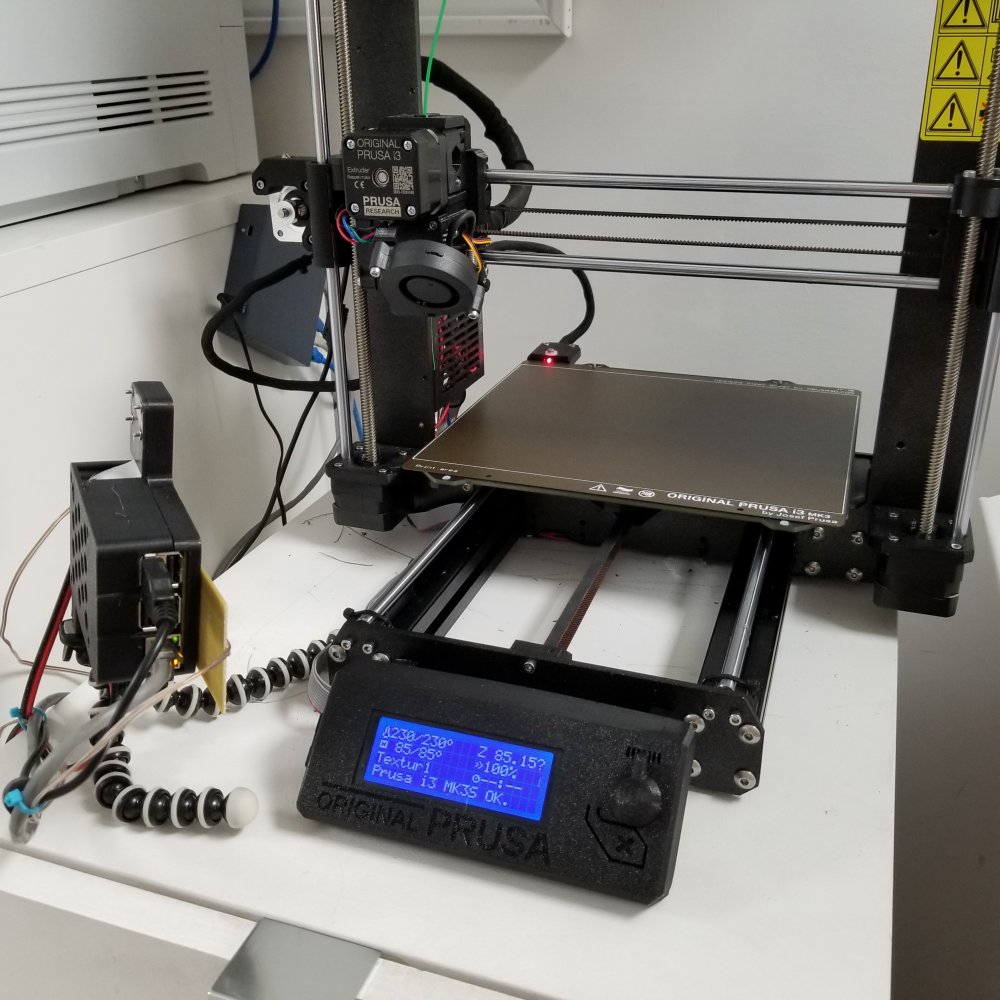

Well, I finished my new Octoprint box using a RPI2B (had one around), built a case for it, and have it running off the 24V printer power supply. I added two big LED lights to light up the printer bed that I can control from Octoprint. Here are some pictures. I designed the case using Alibre. Oh yes, the printer is a Prusa I3MK3S.

The tan things on the side of the box are the LED lights fastened on with hot glue, and the little light inside is a 24V-5V converter. The little box on top is the camera. I used a custom HAT prototype board to mount the converter and a darlington, and a relay to drive the lights. I had an old flexible tripod that I mounted the whole thing on. That way, I can play around with the best place to put the thing.

Another pict. The gray box in the upper left is an Ethernet switch that drives the Octoprint, plus 2 printers (the laser printer seen above, and a Canon Pro-1000).

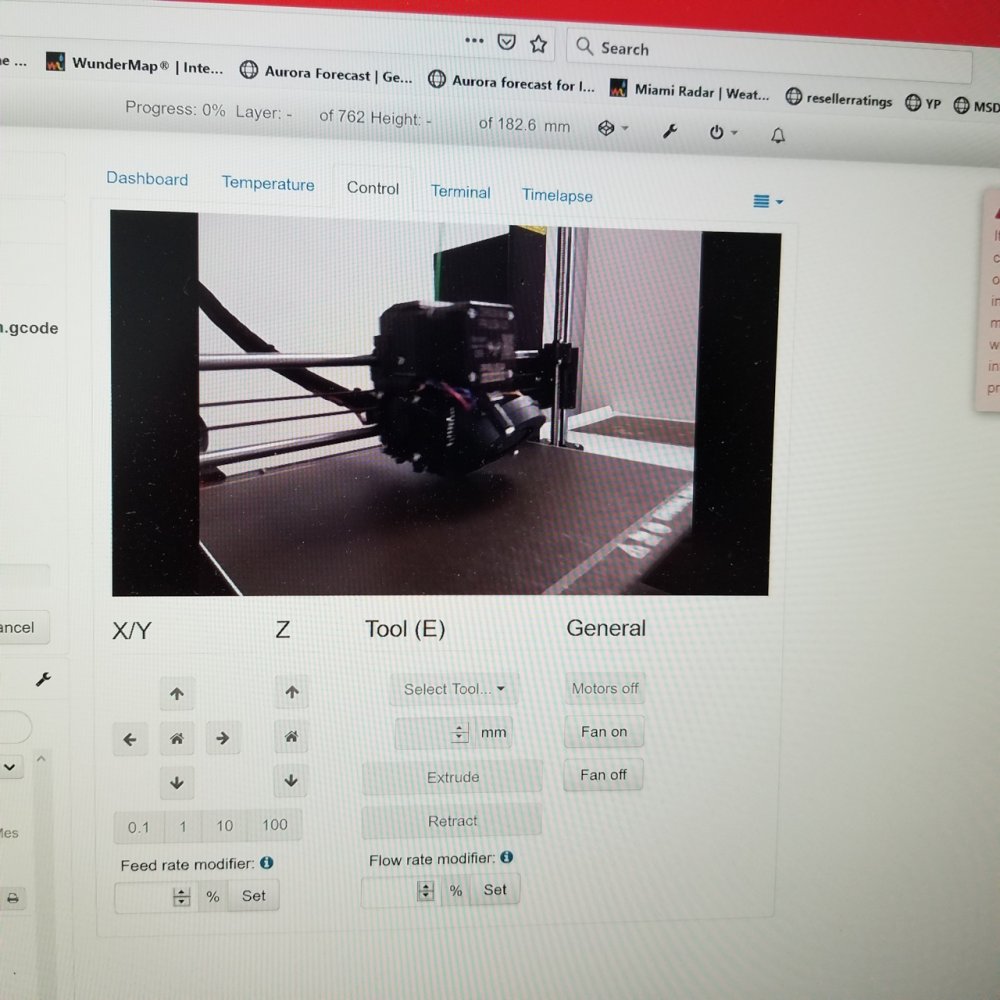

A screenshot of the Octoprint control panel showing the camera. I forgot to turn the LED lights on, but they light up the bed fairly well.

Octoprint is great. No more SD cards. I used a RPI2B 1) because I had it, and 2) it doesn't draw much power so I could run the whole thing off the 24V printer power supply.

The tan things on the side of the box are the LED lights fastened on with hot glue, and the little light inside is a 24V-5V converter. The little box on top is the camera. I used a custom HAT prototype board to mount the converter and a darlington, and a relay to drive the lights. I had an old flexible tripod that I mounted the whole thing on. That way, I can play around with the best place to put the thing.

Another pict. The gray box in the upper left is an Ethernet switch that drives the Octoprint, plus 2 printers (the laser printer seen above, and a Canon Pro-1000).

A screenshot of the Octoprint control panel showing the camera. I forgot to turn the LED lights on, but they light up the bed fairly well.

Octoprint is great. No more SD cards. I used a RPI2B 1) because I had it, and 2) it doesn't draw much power so I could run the whole thing off the 24V printer power supply.