- Joined

- Jan 18, 2010

- Messages

- 16,122

- Reaction score

- 9,083

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

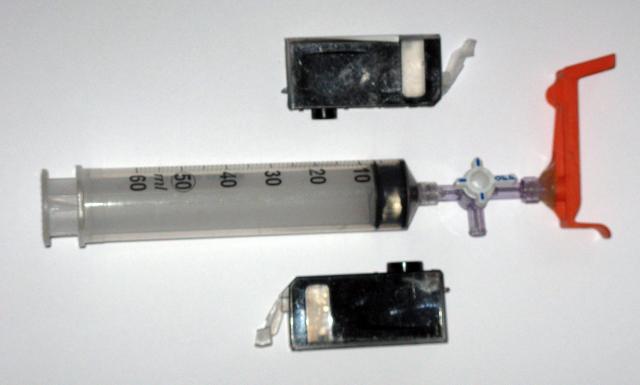

Thank you very much for your great pictures, and sharing your refilling method with us, its really appreciated.gigigogu said:I had a lot more fun and eventually I got it right (with my contraption) - the cartridge filled almost full, in one go, no foam, no wasted ink, no ink left in air maze and upper sponge.

However it needs some physical strength, also the cartridge is under considerable mechanical stress because of vacuum.

If anybody is interested, let me know, to post photos and description.

Your contraption doesnt look very study but it obviously is and thats what counts well done.

What we need now is for more guys to have a go at making up the own contraptions or copying an excising one

and we could possibly make the two oldest refilling methods redundant.

Growing popularity can only be a good thing..

What are you going to call it, The .......refilling method ?