- Thread starter

- #81

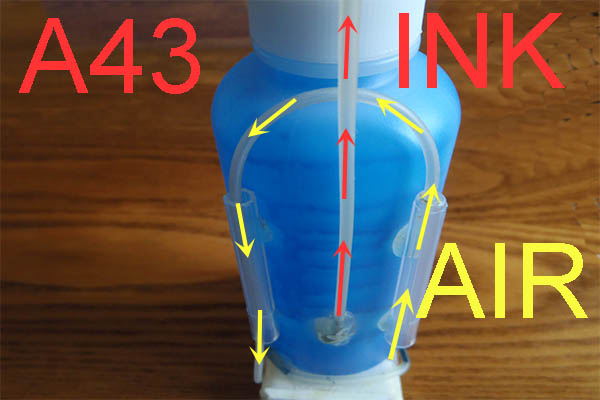

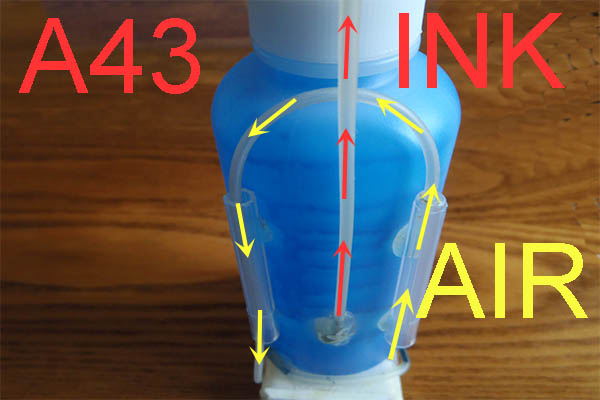

aaa

Printer Guru

It is a bad decision.wss said:or in the cap of the bottle ?

thanks

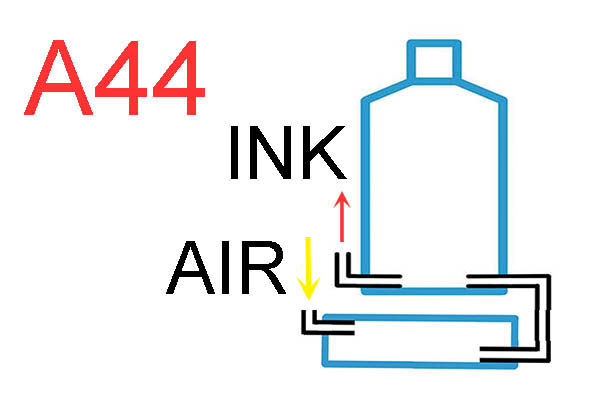

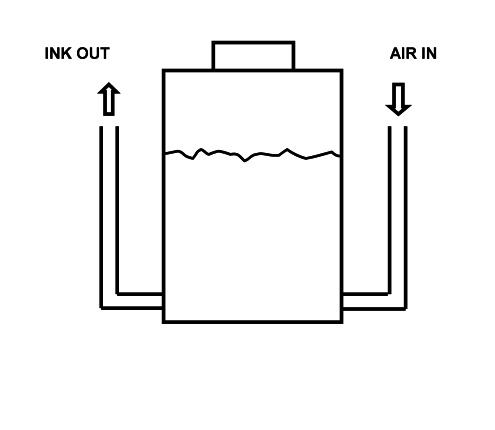

My innovation is that there's no need to do so completely.turbguy said:Can you temporarily block the air vent before and during refilling?