- Joined

- Jan 18, 2010

- Messages

- 16,149

- Reaction score

- 9,104

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Now have 3 Ender-3 V3 Plus SE/

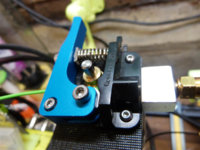

I set out to improve the Extruder performance on my CR-10 by drilling out the hole that the filament passes through before it goes into the Teflon tube that leads down to the hot-end.

I made the hole big enough to allow me to screw a steal 30mm throat (Normally used in a hot-end) right into the plastic block that sits on top of the Extruder motor.

Click to enlarge..

Click to enlarge..

I used a throat that had a small Teflon tube inside it and then added a heating block to it, (Cut in half) which allowed me to fit the Pneumatic Connector to hold the Teflon tubing.

Then I fitted a new Aluminium easy to use arm bracket with an adjustable nut to help increase the pressure on the little filament bearing, I had another Aluminium arm for the other side, but it didn’t suite my current setup, so didn’t use it.

Once assembled it came together nicely and I tested it a piece of green filament before re-attaching the Teflon tube again, the proof of the pudding will be using it to print something, but I’m confident it will work as it’s supposed too..

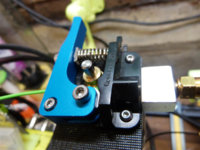

I made the hole big enough to allow me to screw a steal 30mm throat (Normally used in a hot-end) right into the plastic block that sits on top of the Extruder motor.

Click to enlarge..

Click to enlarge.. I used a throat that had a small Teflon tube inside it and then added a heating block to it, (Cut in half) which allowed me to fit the Pneumatic Connector to hold the Teflon tubing.

Then I fitted a new Aluminium easy to use arm bracket with an adjustable nut to help increase the pressure on the little filament bearing, I had another Aluminium arm for the other side, but it didn’t suite my current setup, so didn’t use it.

Once assembled it came together nicely and I tested it a piece of green filament before re-attaching the Teflon tube again, the proof of the pudding will be using it to print something, but I’m confident it will work as it’s supposed too..