Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,406

- Reaction score

- 1,778

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150, Pro10s,,Voron2.4

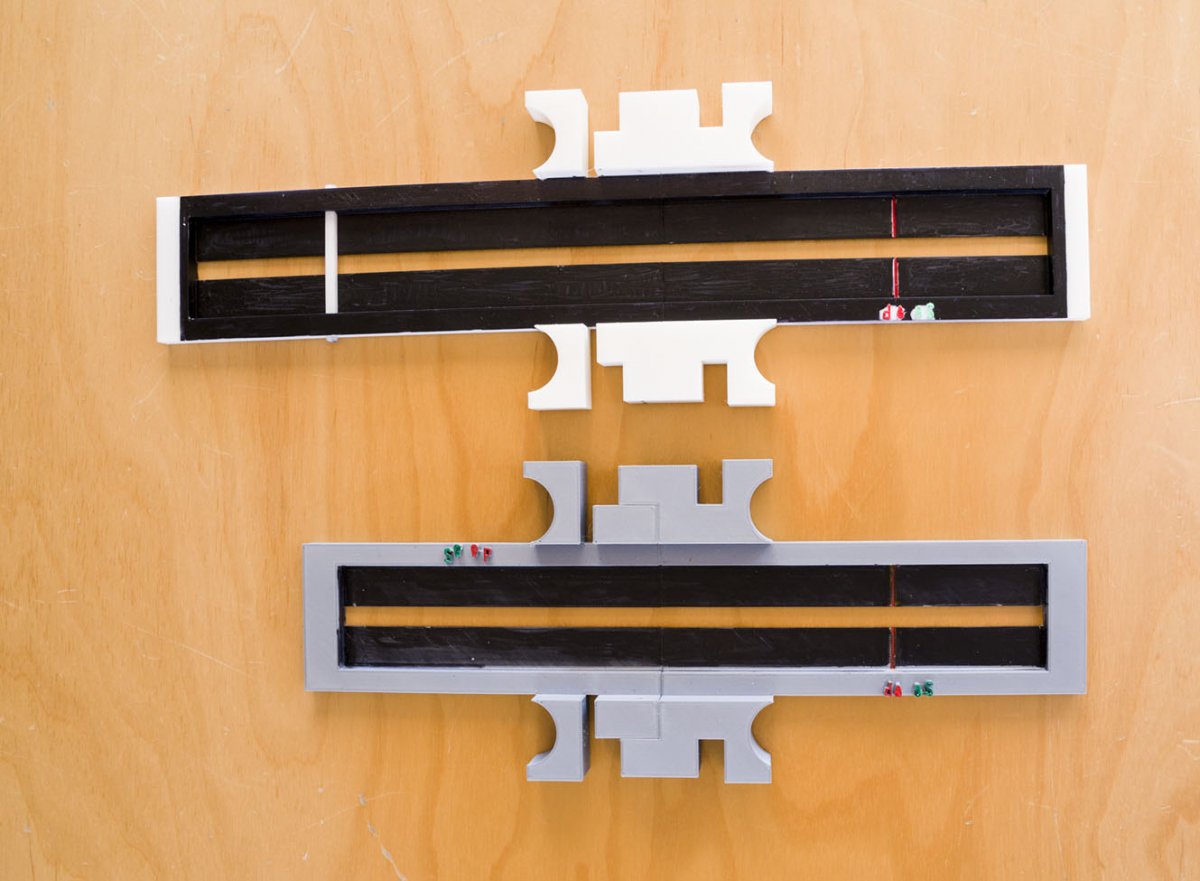

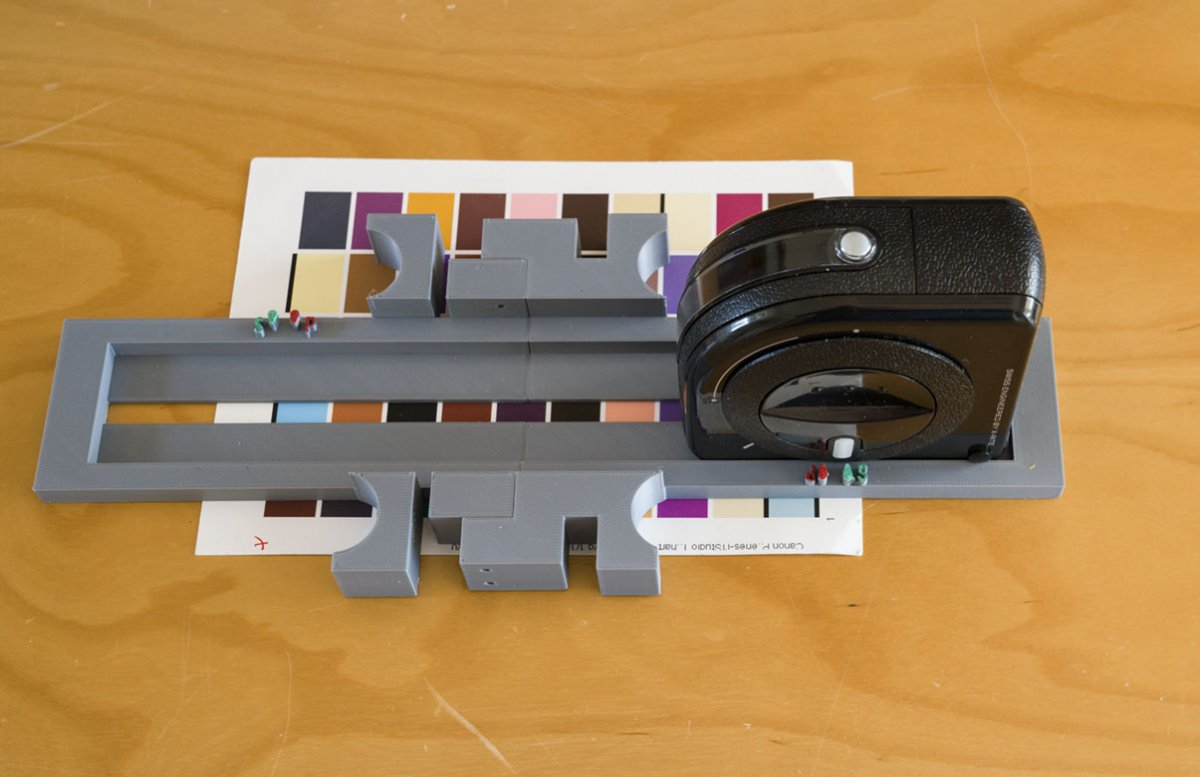

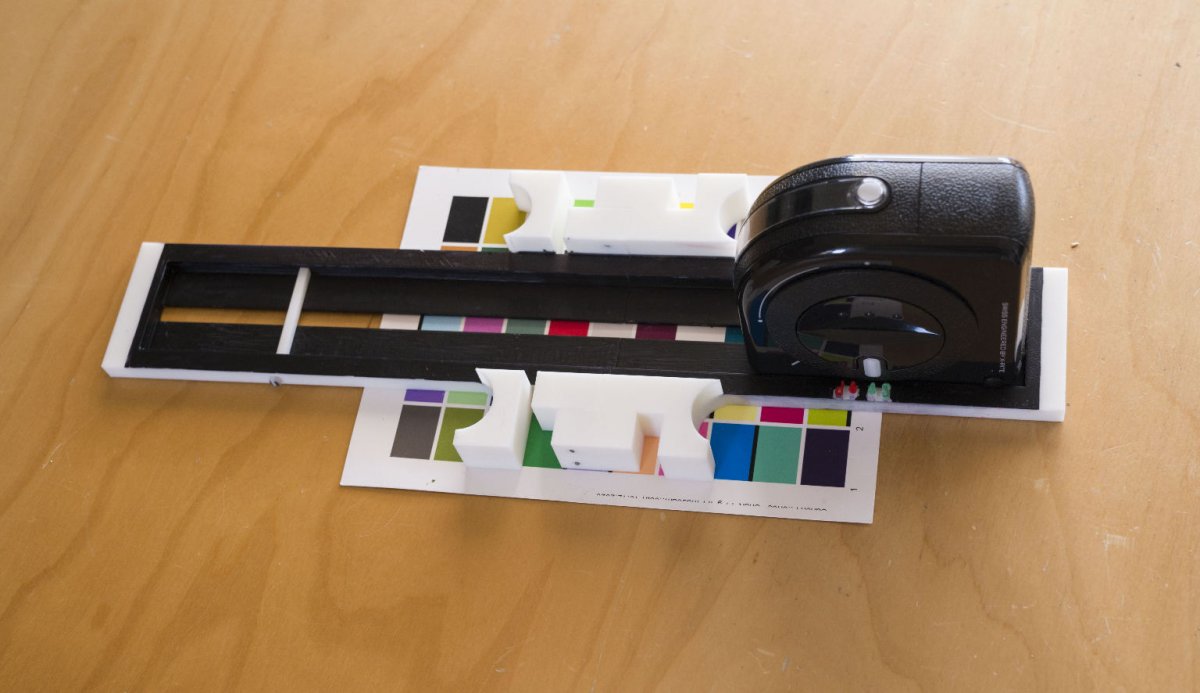

Meet the Color-Munki guide-rulers Mark II and Mark III.

A simple device for guiding the Color Munki/I1studio spectrophotometer along the 5 rows of 10 patches produced by Xrite software (be it the older Color Munki version or the newer I1studio ).

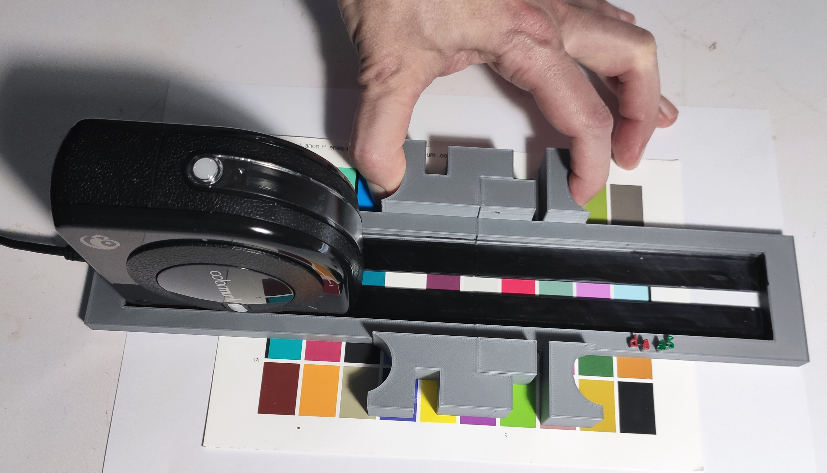

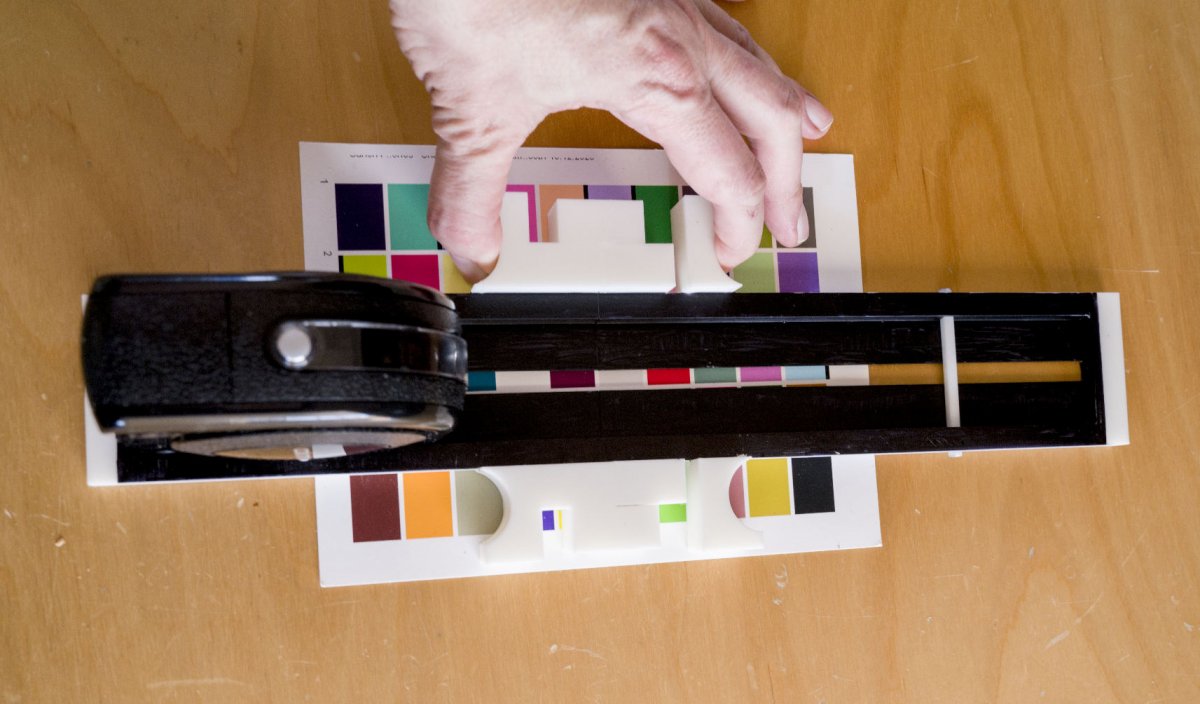

Place the ruler over the sheet of patches, Align the bottom edge of the row just above the red line of the guide. Place the Color Munki all the way back into the inner channel of the guide. The sensor will be aligned with the green arrow at left. Click the CM button, slide the device along the ruler until it reaches the end-stop and release the button. Repeat for each row.

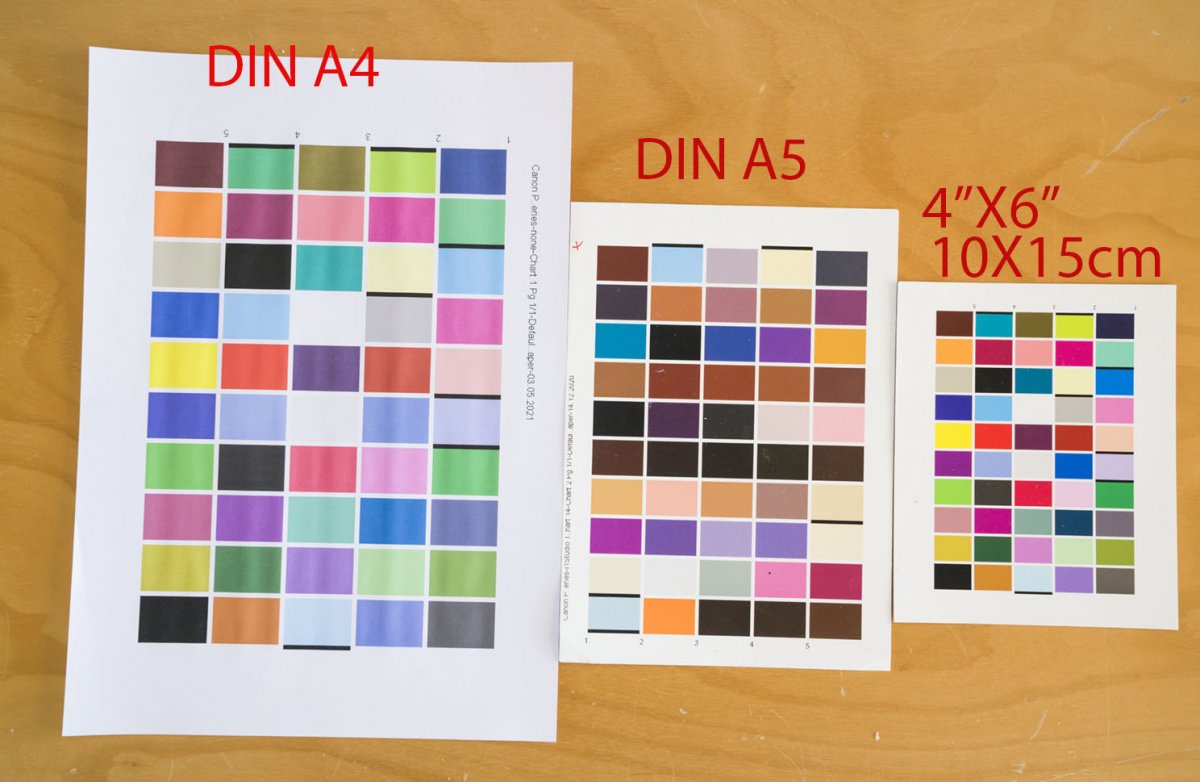

To people not familiar with the I1studio soft, it has to be clarified that the X-rite program prints, at user’s choice, one A4 sheet of 50 rows or two A5 sheets of 25 patches each, You have to scan these sheet(s) afterwards with the Color Munki device to obtain the profile.

In fact, is a two stages affair. After the first A4 sheet has been scanned, the program calculates a second set, for fine tuning the profile, that you have to scan as well.

Thus, in normal use you need two A4 sheets of photo paper to obtain the final profile.

If you want to use only one A5 sheet for all 50 patches in order to save expensive photo paper, you have to cheat a bit. Select A4 size in I1studio, then go to the printer driver and click ‘print adjusted to paper’. Choose document size: A4 and printer size: A5. I1studio will send an A4 document to the printer but the driver scales down the size to DIN-A5 (or whatever size you want).

The first working version ( Mark II, in grey ) is tailored for A5 sheets.

The latest version of the ruler (Mark III) accepts sheets up to DIN-A4 I added a removable rod (in white) that works as a hard stop. This rod must be inserted for scanning A5 size, so you don’t surpass the edge of the paper (which might trigger an error ).

The round hollow shaped parts on both sides are for holding the ruler with the thumb and index fingers, so it doesn’t moves while you slide the Color Munki with the other hand.

I.e. if you’re right handed, move the Color Munki with your right hand and hold steadily the ruler with the fingers of your left hand, Vice versa if you’re left handed.

Due to the limitations of my printer (X-axis up to 25cm. ) these rulers had been printed in two parts which were glued-nailed afterwards. Therefore the weird shape, due to the joining parts. Sure it could look better with a little redesign, but I kind of like it this way.

There has been Mark 0 and a Mark I prototypes. None were really operative, so they didn’t reach the final stage. Only the lower part was printed.

Using this guide I was able to scan without problems a sheet of 50 patches printed in a 10x15cm sheet of paper. That’s roughly A6 size. Therefore, with a single A4 sheet you can print 4 pages of 50 patches.

People with steady hands will be able to do that as well without any help, but I’m already a bit parkinsonian, so this device comes handy for me.

You may argue that since the patches are smaller, the precision of the profile will be affected. I think that if you move the Color Munki at a slower pace with smaller papers, the number of samples picked by the device is approximately the same and the difference between a profile obtained with an A4 sheet vs A5 or A6 will be negligible.

The proof is in the pudding though and further testing will be required to check this matter.

I know that neither the gray-silver filament used for Mark II nor the white used for Mark III are the best options but it’s what I had available, Painting them in black it’s a solution but,as you can see in the photos, my painting skills are rather poor so next time I’ll use black filament. (I’ll consider green as well if @The Hat fancies one of these rulers. ).

A simple device for guiding the Color Munki/I1studio spectrophotometer along the 5 rows of 10 patches produced by Xrite software (be it the older Color Munki version or the newer I1studio ).

Place the ruler over the sheet of patches, Align the bottom edge of the row just above the red line of the guide. Place the Color Munki all the way back into the inner channel of the guide. The sensor will be aligned with the green arrow at left. Click the CM button, slide the device along the ruler until it reaches the end-stop and release the button. Repeat for each row.

To people not familiar with the I1studio soft, it has to be clarified that the X-rite program prints, at user’s choice, one A4 sheet of 50 rows or two A5 sheets of 25 patches each, You have to scan these sheet(s) afterwards with the Color Munki device to obtain the profile.

In fact, is a two stages affair. After the first A4 sheet has been scanned, the program calculates a second set, for fine tuning the profile, that you have to scan as well.

Thus, in normal use you need two A4 sheets of photo paper to obtain the final profile.

If you want to use only one A5 sheet for all 50 patches in order to save expensive photo paper, you have to cheat a bit. Select A4 size in I1studio, then go to the printer driver and click ‘print adjusted to paper’. Choose document size: A4 and printer size: A5. I1studio will send an A4 document to the printer but the driver scales down the size to DIN-A5 (or whatever size you want).

The first working version ( Mark II, in grey ) is tailored for A5 sheets.

The latest version of the ruler (Mark III) accepts sheets up to DIN-A4 I added a removable rod (in white) that works as a hard stop. This rod must be inserted for scanning A5 size, so you don’t surpass the edge of the paper (which might trigger an error ).

The round hollow shaped parts on both sides are for holding the ruler with the thumb and index fingers, so it doesn’t moves while you slide the Color Munki with the other hand.

I.e. if you’re right handed, move the Color Munki with your right hand and hold steadily the ruler with the fingers of your left hand, Vice versa if you’re left handed.

Due to the limitations of my printer (X-axis up to 25cm. ) these rulers had been printed in two parts which were glued-nailed afterwards. Therefore the weird shape, due to the joining parts. Sure it could look better with a little redesign, but I kind of like it this way.

There has been Mark 0 and a Mark I prototypes. None were really operative, so they didn’t reach the final stage. Only the lower part was printed.

Using this guide I was able to scan without problems a sheet of 50 patches printed in a 10x15cm sheet of paper. That’s roughly A6 size. Therefore, with a single A4 sheet you can print 4 pages of 50 patches.

People with steady hands will be able to do that as well without any help, but I’m already a bit parkinsonian, so this device comes handy for me.

You may argue that since the patches are smaller, the precision of the profile will be affected. I think that if you move the Color Munki at a slower pace with smaller papers, the number of samples picked by the device is approximately the same and the difference between a profile obtained with an A4 sheet vs A5 or A6 will be negligible.

The proof is in the pudding though and further testing will be required to check this matter.

I know that neither the gray-silver filament used for Mark II nor the white used for Mark III are the best options but it’s what I had available, Painting them in black it’s a solution but,as you can see in the photos, my painting skills are rather poor so next time I’ll use black filament. (I’ll consider green as well if @The Hat fancies one of these rulers. ).