- Joined

- Jan 18, 2010

- Messages

- 16,126

- Reaction score

- 9,084

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

My new beast started with a bang, firstly when it started to print the extruder was 20 mm from the platform, hey that’s not right, what the hell is happening here, it turned out a wire had got snagged in the micro switch limiter and added the extra height, start again...

The second and third and fourth time I got a bungle of fluffy plastic because nothing would seem to stich to the glass, Then I realized I was using ABS filament, so back to re-calibrate the extruder and platform again, this time to a much lower height.

Got going again and this time I was cooking with gas but as usual the head was hitting the plastic because it was set a bit too low, but I persisted and sure enough when it had finished the outer brim skirt it settled down.

It printed for about 3 hours when I noticed both my models were coming apart in places, O’ s**t the temperature was set to low for this Friggin ABS and I had to stop the printer, it was definitely time to change to PLA.

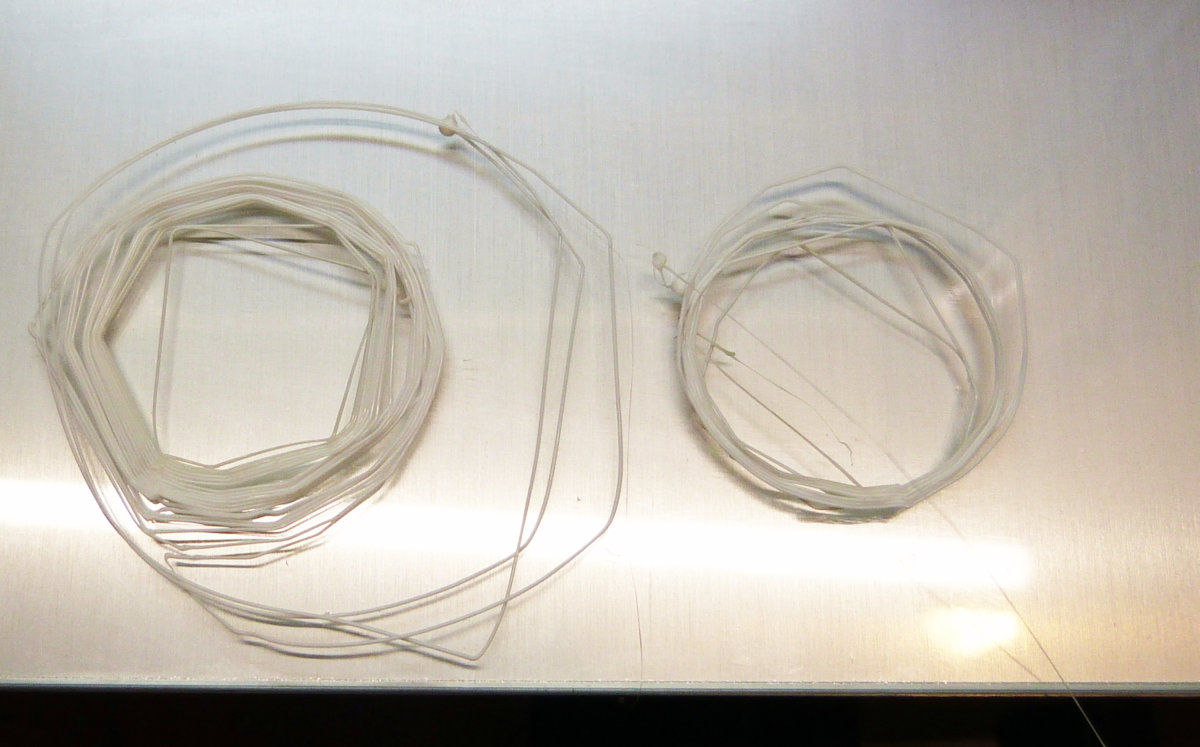

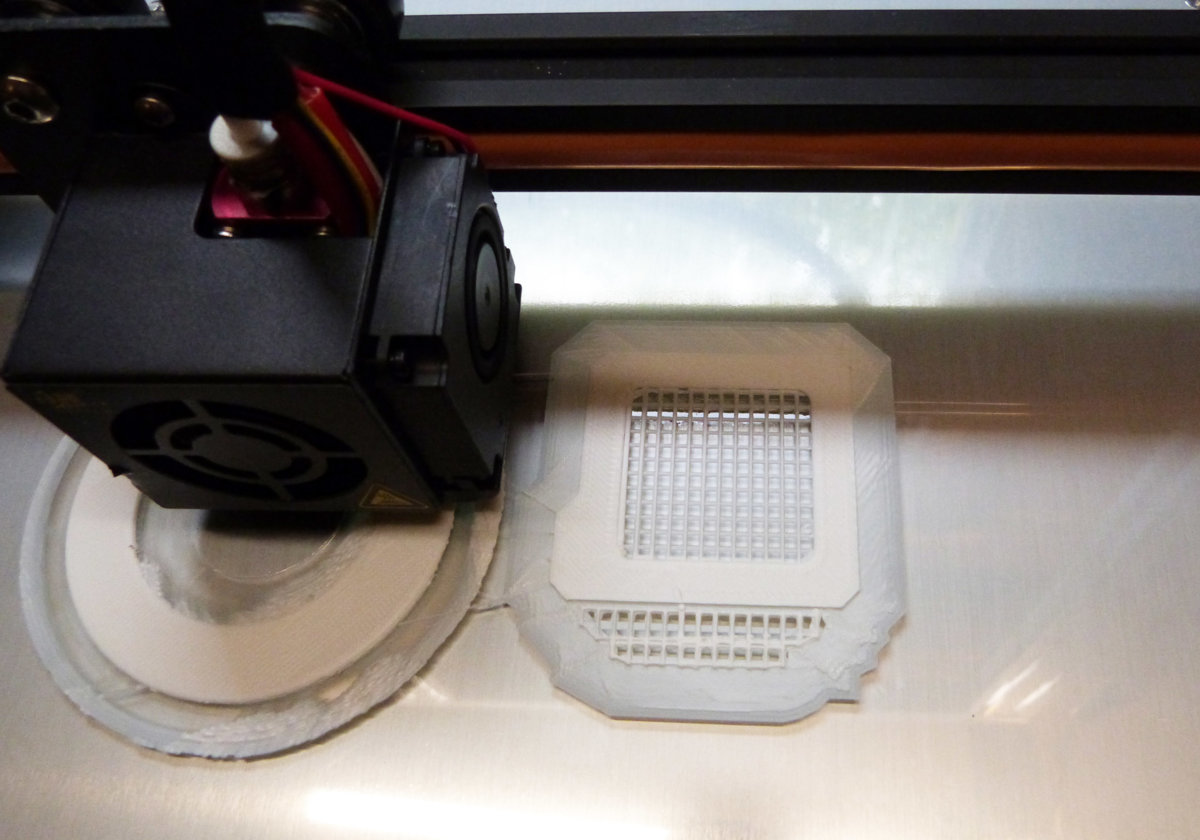

Got it going on PLA this morning but again I had trouble getting the darn thing to stick to the glass, I was forced to use lots of hair spray, and finally we were making our first two models, one is an inner core for the reels of filament which screws together with a locking nut to hold the reel on securely, and second was a dust cover for the mechanism that feeds the filament to the main heated extruder head, it later came unstuck also, back to the drawing board.

So far not very good results, but I reckon a bit more work is needed to get to grips with this new machine, the MS mini was so much easier, I may have had similar problems starting off but the mini was easier to work through the issues...

Now back at it again tonight and I would say I’m making progress but that’s only if the model stays stuck down this time...

More later...

The second and third and fourth time I got a bungle of fluffy plastic because nothing would seem to stich to the glass, Then I realized I was using ABS filament, so back to re-calibrate the extruder and platform again, this time to a much lower height.

Got going again and this time I was cooking with gas but as usual the head was hitting the plastic because it was set a bit too low, but I persisted and sure enough when it had finished the outer brim skirt it settled down.

It printed for about 3 hours when I noticed both my models were coming apart in places, O’ s**t the temperature was set to low for this Friggin ABS and I had to stop the printer, it was definitely time to change to PLA.

Got it going on PLA this morning but again I had trouble getting the darn thing to stick to the glass, I was forced to use lots of hair spray, and finally we were making our first two models, one is an inner core for the reels of filament which screws together with a locking nut to hold the reel on securely, and second was a dust cover for the mechanism that feeds the filament to the main heated extruder head, it later came unstuck also, back to the drawing board.

So far not very good results, but I reckon a bit more work is needed to get to grips with this new machine, the MS mini was so much easier, I may have had similar problems starting off but the mini was easier to work through the issues...

Now back at it again tonight and I would say I’m making progress but that’s only if the model stays stuck down this time...

More later...