My printer won't stop trying to clean its print heads. So in an act of desperation I took the whole thing apart to try and understand how it decides on success for the cleaning routine. Here is what I found so far:

1. The waste tank has this enormous sponge inside. It was saturated and ink was sloshing around in the bottom. What a mess but I cleaned it all up and washed the sponge.

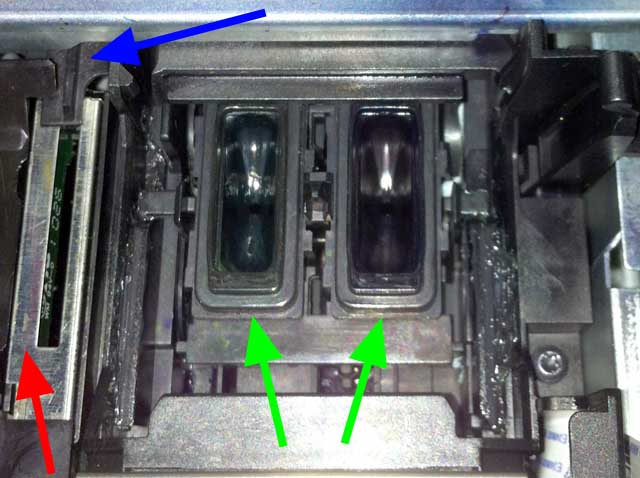

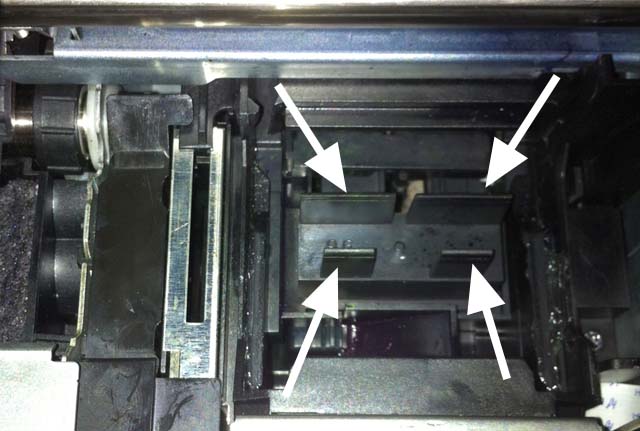

2. There is a small peristaltic pump connected to what looks like two rectangular rubber funnels on a movable cart. When the cart gets moved under the print heads they suck on the printheads and force ink through them. At the same time Some of the lines get pinched. Ink first gets sucked into a little canister and then purged into the bigger waste tank with the sponge.

3. There are four (two for each) rubber wipers on that same movable cart. They just wipe off dried ink from the nozzle area.

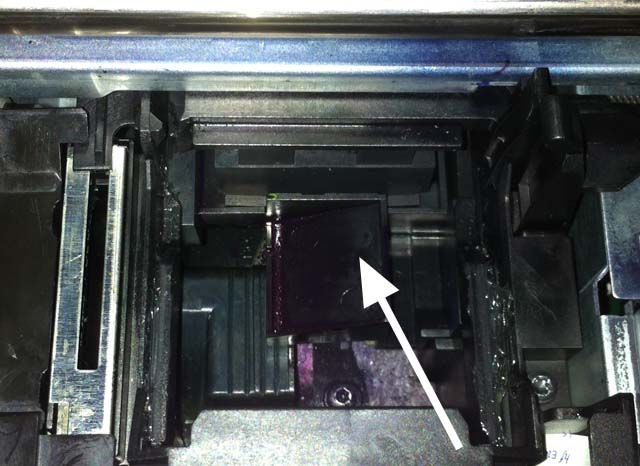

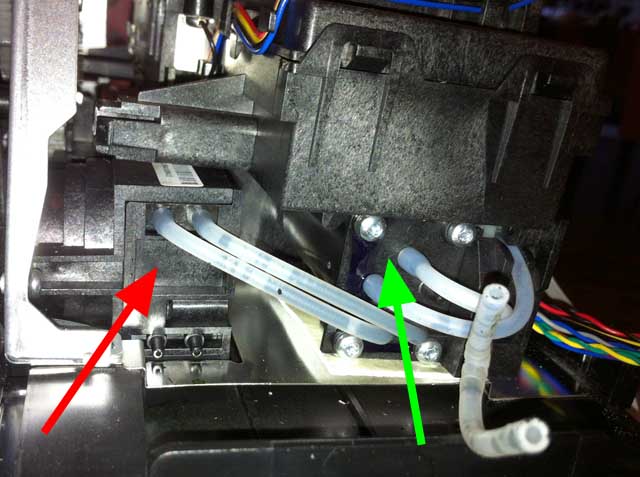

4. Now comes the mystery part. None of the above has any sorts of smarts or sensors to "know" if the cleaning did anything. However, here is a small PCB in a plastic cover on the left side of the cleaning unit. It also empties into the waste tank. It has a metal antenna (my guess) with a rectangular opening and a second metal shield. The opening has plastic sliding cover that at times covers the opening (when the cleaning cart moves to the back) and then snapps back again pulled by a spring. The circuit board has a single OpAmp. And then this is connected to the main PCB. For lack of better description the metal cover looks like a WiFi antenna. And it is connected to the PCB.

Has anyone any information on what this device does and how it works exactly? Is it some sort of flow meter? Does it measure whether the spray passing through it is dense enough? The printheads seem to spray to a little blast plate angled at 45 degrees in the waste tank. I was not able to see whether they also spray through this mystery device. If not how does the mystery devise measure? And what's with the moving cover?

In my case I am able to make my printheads happy when soaking them in cleaning solution to the point where they show some acceptable blot pattern for all 4 colors. But when I put them back into the printer it literally keeps sucking on the yellow for 10 minutes or more until the tank is empty. In the process it all craps up and if I get lucky to where decides to finally print most colors are missing. When I take the heads out and put them on moist paper the is no blotting pattern. WTF.

I have two running theories?

1. The refill pigment ink (NanoDigital pigment) I am using is so bad it clogs some of the nozzles right away during the test shots in the cleaning cycle.

2. The mystery device is broken. As a result the ink delivery system can not keep up with ink consumption during the sucking on the heads?

I lean towards 1. because when I do get the printer to print it remains in whatever state it then is. In other words once it makes it through one of these super extensive cleaning routines to the point where it actually prints a test pattern one or more colors are impaired to various degrees. And that streak pattern remains. Doesn't get better, doesn't get worse. If I decide to re-do the ordeal I might end up with one or two colors looking better and another being completely gone. And it remains in that state. To me this spells nozzle clogs. I have not (yet) found a way to remove and clean the heads without the printer noticing. Ideas?

I am frustrated - too bad I am not living in a 10 story high-rise. Else this printer would have had an accidental fall to its death by now......

1. The waste tank has this enormous sponge inside. It was saturated and ink was sloshing around in the bottom. What a mess but I cleaned it all up and washed the sponge.

2. There is a small peristaltic pump connected to what looks like two rectangular rubber funnels on a movable cart. When the cart gets moved under the print heads they suck on the printheads and force ink through them. At the same time Some of the lines get pinched. Ink first gets sucked into a little canister and then purged into the bigger waste tank with the sponge.

3. There are four (two for each) rubber wipers on that same movable cart. They just wipe off dried ink from the nozzle area.

4. Now comes the mystery part. None of the above has any sorts of smarts or sensors to "know" if the cleaning did anything. However, here is a small PCB in a plastic cover on the left side of the cleaning unit. It also empties into the waste tank. It has a metal antenna (my guess) with a rectangular opening and a second metal shield. The opening has plastic sliding cover that at times covers the opening (when the cleaning cart moves to the back) and then snapps back again pulled by a spring. The circuit board has a single OpAmp. And then this is connected to the main PCB. For lack of better description the metal cover looks like a WiFi antenna. And it is connected to the PCB.

Has anyone any information on what this device does and how it works exactly? Is it some sort of flow meter? Does it measure whether the spray passing through it is dense enough? The printheads seem to spray to a little blast plate angled at 45 degrees in the waste tank. I was not able to see whether they also spray through this mystery device. If not how does the mystery devise measure? And what's with the moving cover?

In my case I am able to make my printheads happy when soaking them in cleaning solution to the point where they show some acceptable blot pattern for all 4 colors. But when I put them back into the printer it literally keeps sucking on the yellow for 10 minutes or more until the tank is empty. In the process it all craps up and if I get lucky to where decides to finally print most colors are missing. When I take the heads out and put them on moist paper the is no blotting pattern. WTF.

I have two running theories?

1. The refill pigment ink (NanoDigital pigment) I am using is so bad it clogs some of the nozzles right away during the test shots in the cleaning cycle.

2. The mystery device is broken. As a result the ink delivery system can not keep up with ink consumption during the sucking on the heads?

I lean towards 1. because when I do get the printer to print it remains in whatever state it then is. In other words once it makes it through one of these super extensive cleaning routines to the point where it actually prints a test pattern one or more colors are impaired to various degrees. And that streak pattern remains. Doesn't get better, doesn't get worse. If I decide to re-do the ordeal I might end up with one or two colors looking better and another being completely gone. And it remains in that state. To me this spells nozzle clogs. I have not (yet) found a way to remove and clean the heads without the printer noticing. Ideas?

I am frustrated - too bad I am not living in a 10 story high-rise. Else this printer would have had an accidental fall to its death by now......