- Joined

- Jan 18, 2010

- Messages

- 15,970

- Reaction score

- 8,962

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

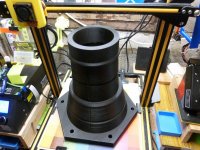

I was thinking of making a new standard lamp in the old style and the full height too, it will be a challenge and if it succeeds, I’ll be over the moon.

Latern type...

Latern type... This shape and dimensions...

This shape and dimensions...

I am going to use all black filament this time and start at the bottom and work up, instead of making individual pieces willy nilly, when I reach the height I require, I’ll then try to design the lanterns, and get them to fit.

I’m hoping to hang 3 lanterns from the centre shaft by using a half circle curve and attaching the lanterns from the top to hang down, this of course is all speculation, what I end up with is going to be anybody’s guess.

It’s not going to be easy and will take quite some time firstly to design it, then print it, and I reckon the printing time for the base of the lamp will be in excess of 72 hours using as much as 1kg of filament.

If I can make the design to fit on my CR-10 maximum 30 x30 x30cm and can finish the print without over stressing the poor Auld machine will be interesting because I reckon this project will take about 200 hours to complete and use around 4kg plus of filament...

I am hoping to print the base in one go without the need for 1 or more prototypes, but I’ll need several attempts at getting the vertical shafts to fit snuggly, plus another half dozen goes at making the light holders (Lanterns), then cutting the glass to fit them, not to mention the curved hollow tubing....

Is this a bridge to far...Only time will tell all...?

O’ don’t expect this project to be finished any time soon, if I can complete it in six months then I’ll be doing well if at all, because I have another life, as I’m being constantly reminded by the powers that be..

P.S. is there anyone out there doing anything on their 3D printers at all, everyone seems to have gone quiet of late....

Latern type...

Latern type... This shape and dimensions...

This shape and dimensions...I am going to use all black filament this time and start at the bottom and work up, instead of making individual pieces willy nilly, when I reach the height I require, I’ll then try to design the lanterns, and get them to fit.

I’m hoping to hang 3 lanterns from the centre shaft by using a half circle curve and attaching the lanterns from the top to hang down, this of course is all speculation, what I end up with is going to be anybody’s guess.

It’s not going to be easy and will take quite some time firstly to design it, then print it, and I reckon the printing time for the base of the lamp will be in excess of 72 hours using as much as 1kg of filament.

If I can make the design to fit on my CR-10 maximum 30 x30 x30cm and can finish the print without over stressing the poor Auld machine will be interesting because I reckon this project will take about 200 hours to complete and use around 4kg plus of filament...

I am hoping to print the base in one go without the need for 1 or more prototypes, but I’ll need several attempts at getting the vertical shafts to fit snuggly, plus another half dozen goes at making the light holders (Lanterns), then cutting the glass to fit them, not to mention the curved hollow tubing....

Is this a bridge to far...Only time will tell all...?

O’ don’t expect this project to be finished any time soon, if I can complete it in six months then I’ll be doing well if at all, because I have another life, as I’m being constantly reminded by the powers that be..

P.S. is there anyone out there doing anything on their 3D printers at all, everyone seems to have gone quiet of late....