- Joined

- Nov 3, 2004

- Messages

- 3,143

- Reaction score

- 1,521

- Points

- 337

- Location

- Bay Area CA

- Printer Model

- CR-10, i560 ,MFC-7440N

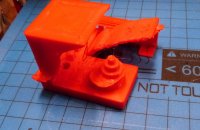

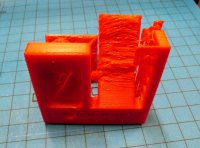

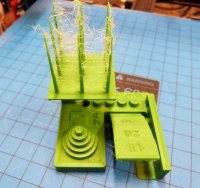

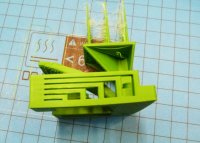

This is very interesting!

Autodesk and Kickstarter teamed up to create this torture test for 3D printers:

Info: https://www.kickstarter.com/blog/toward-better-3d-printers-a-new-test-from-autodesk-and-kickstart

Github info & files: https://github.com/kickstarter/kickstarter-autodesk-3d/blob/master/FDM-protocol/README.md

I think this thing is brilliant! Seems to cover almost everything needed. I love that they have a somewhat objective scale from 1-5 on the various tests.

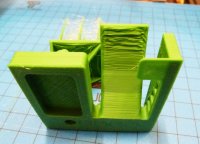

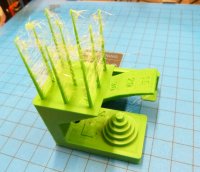

I got a bunch of cheap filament that was on sale ($8 a 1kg roll + free shipping), so I think I'm going to run this test on the filament I'm currently using and then this filament... using the exact same settings... and see what we get!

Autodesk and Kickstarter teamed up to create this torture test for 3D printers:

Info: https://www.kickstarter.com/blog/toward-better-3d-printers-a-new-test-from-autodesk-and-kickstart

Github info & files: https://github.com/kickstarter/kickstarter-autodesk-3d/blob/master/FDM-protocol/README.md

I think this thing is brilliant! Seems to cover almost everything needed. I love that they have a somewhat objective scale from 1-5 on the various tests.

I got a bunch of cheap filament that was on sale ($8 a 1kg roll + free shipping), so I think I'm going to run this test on the filament I'm currently using and then this filament... using the exact same settings... and see what we get!