paulcroft

Fan of Printing

- Joined

- Jan 11, 2010

- Messages

- 75

- Reaction score

- 44

- Points

- 58

- Printer Model

- Canon Pro-100

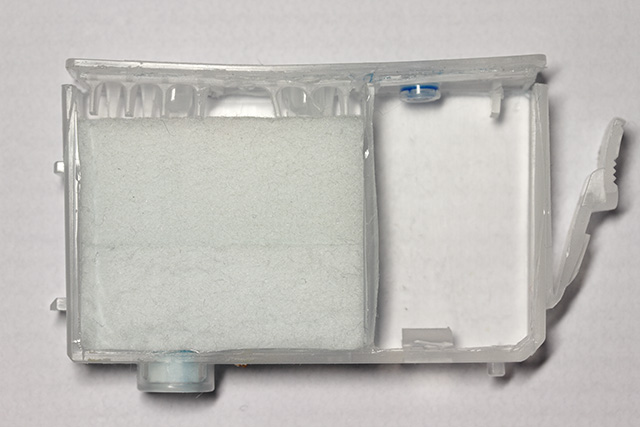

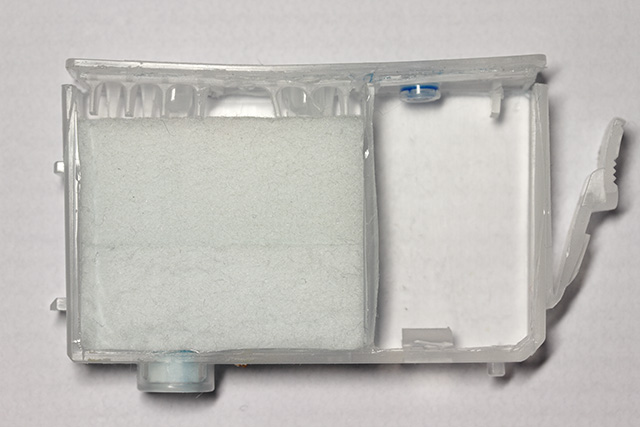

I had some time on hand today so I cut the side out of a spare BCI-6 cartridge to see how it's made. These

cartridges cost a lot to buy new so I thought it would be interesting to see what goes into them and whether

it was possible to ponder on how much R & D went into their design. And to wonder whether cheaper copies

are as well made. Then I thought I'd photograph it and label what I found interesting:

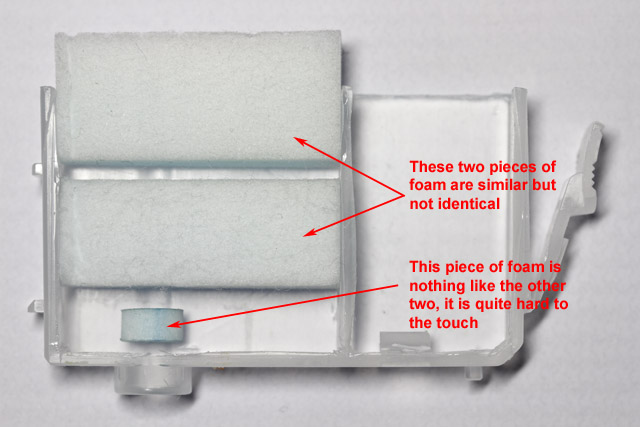

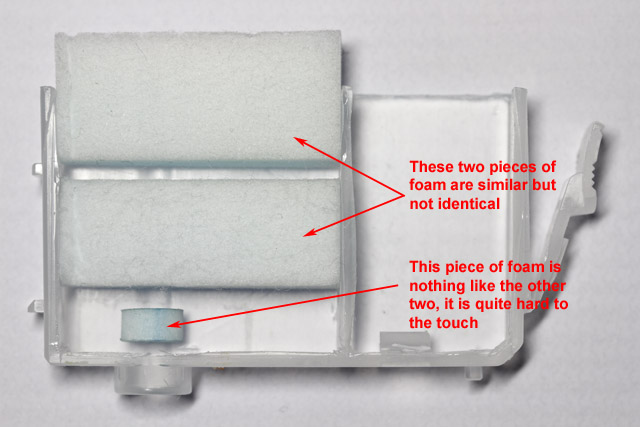

There are three pieces of foam, not two. The small, oval shaped plug through which the ink is fed to the nozzles

is surprisingly rigid and not like the other two pieces at all:

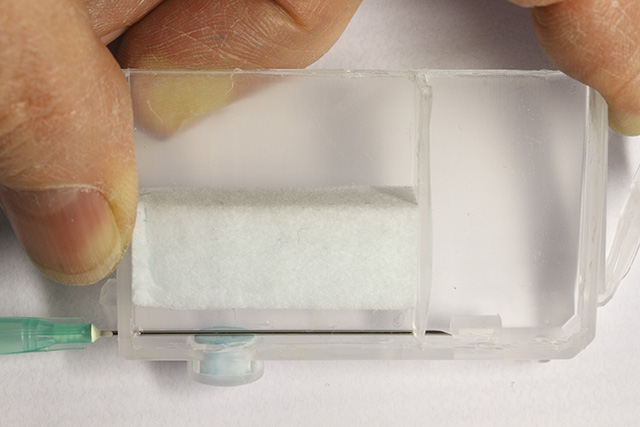

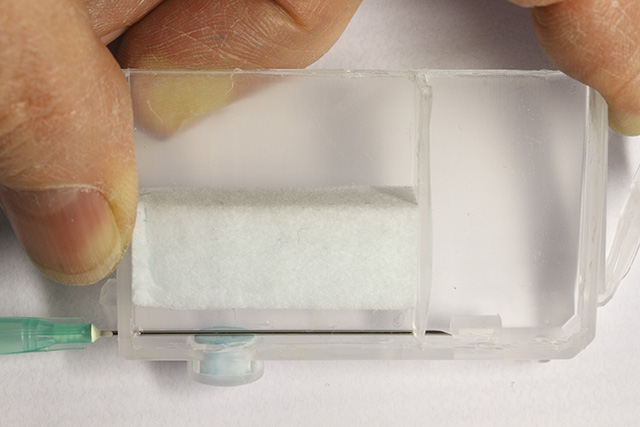

The separator between the ink chamber and the foam chamber has a rectangular hole in the bottom to allow the

ink to feed through. This is where the needle goes when refilling with the 'German' method. Does anybody not

use this method nowadays?

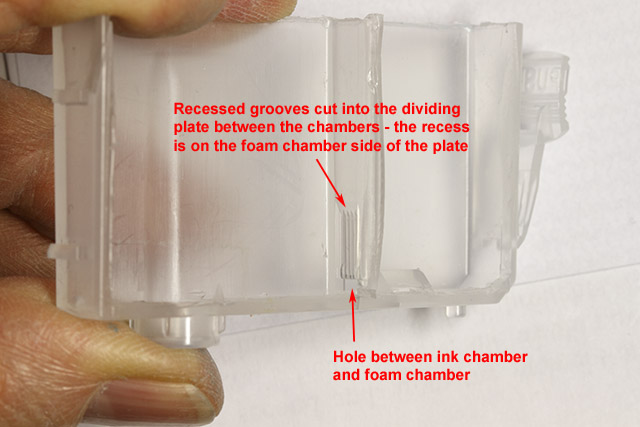

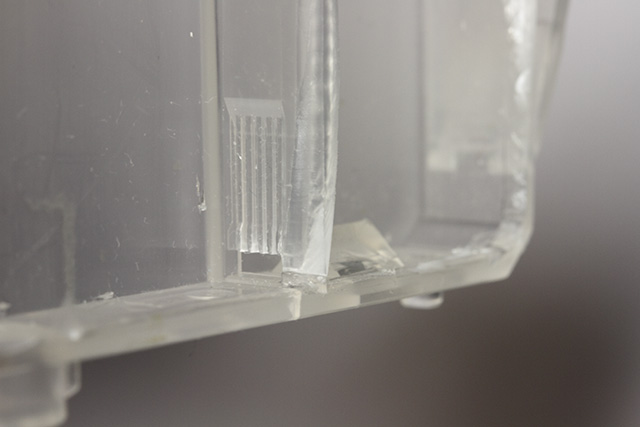

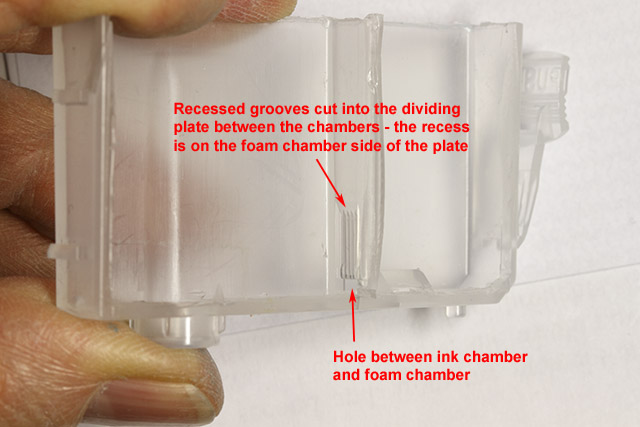

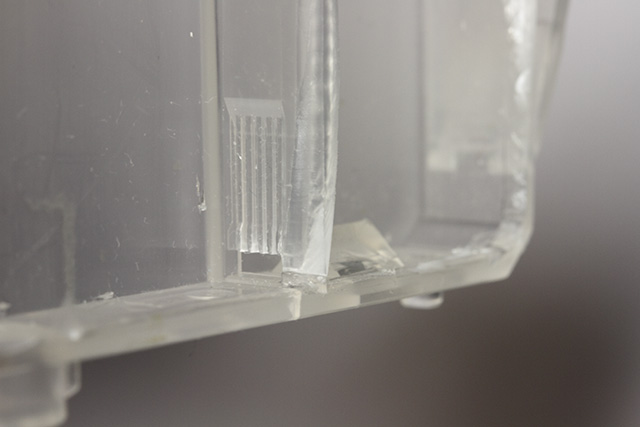

Immediately above this hole, and on the side of the separator facing the foam chamber, are a number of grooves

which are recessed into the plate:

Here is a close up of the grooves:

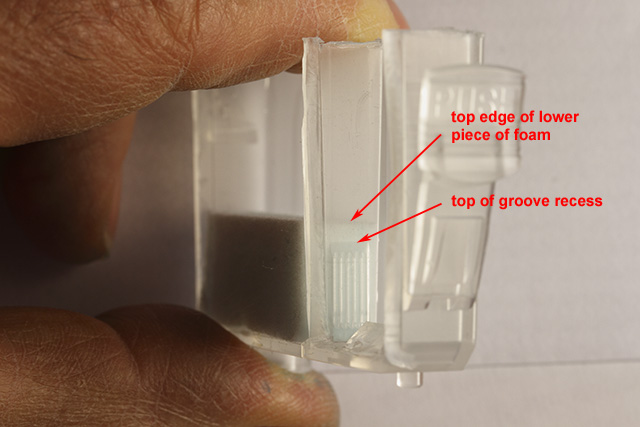

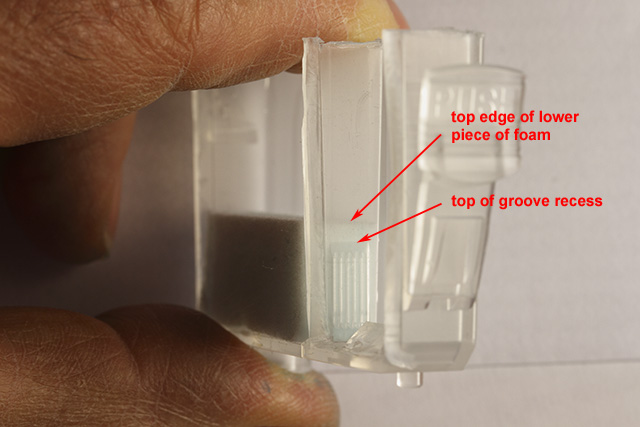

And this is what they look like from the other side. Note that the recess stops below the top edge of the lower foam:

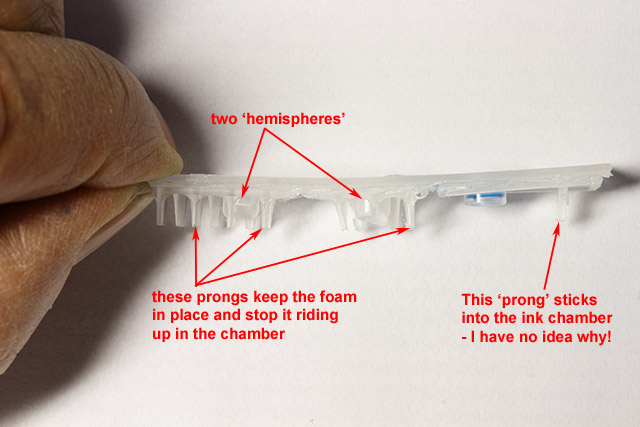

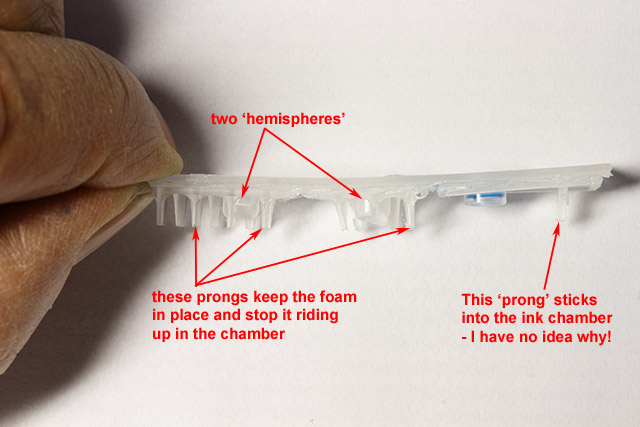

Now here's what, for me, is the really interesting part - the top plate. There are a number of 'prongs' which keep

the foam in place. There's a similar shaped 'prong' in the ink chamber side too which appears to serve no purpose

whatsoever. But do you see those two bulges which resemble hemispheres? They've not come out too clearly in

this photo (they are clearer in my first photo) but they are hollow, i.e. they're recessed from above but there's no

hole in them. It's like they are expansion chambers of some kind. I wonder what purpose they serve?

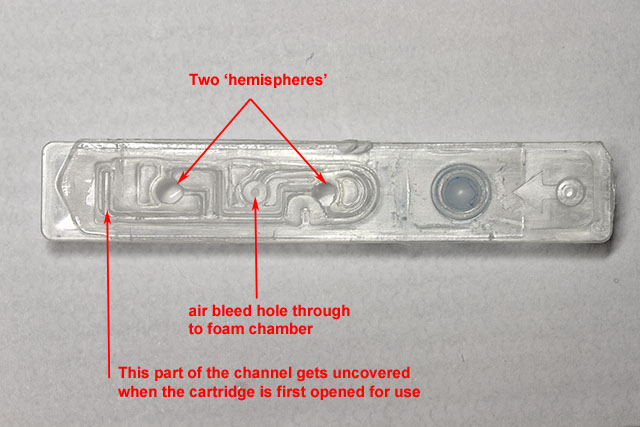

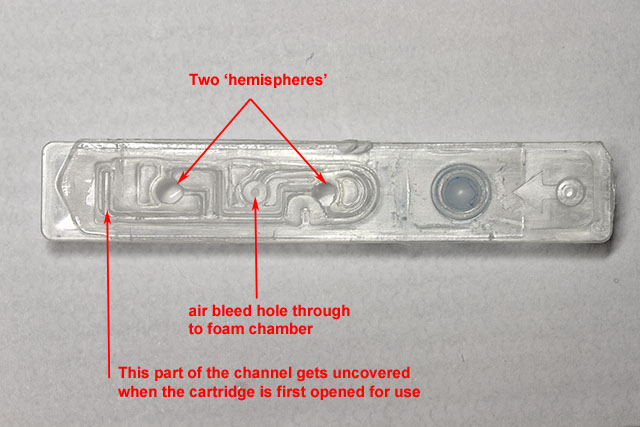

Now look at the top plate from above, with the label peeled off. Follow the path of the air channel groove from its

vent to atmosphere through to the bleed hole into the foam chamber. See how, before getting there, it goes from

the vent to atmosphere first through the left-hand hemispherical chamber, then out again, then through the

right-hand hemishperical chamber and out again before finally reaching the air bleed into the foam chamber.

And the path it follows is not the most obvious one. I'd love to know the science behind this and how it came to be

designed this way.

Anyway, I hope you found this as interesting as I did. I'm now using a Canon Pro9000 II which uses CLI-8 cartridges

but the design appears to be virtually identical, apart from the chip. To my mind it goes some way to explaining that

there's a lot more to an ink cartridge than one might, at first glance, think.

Paul

Edit: In the original post I inadvertently called this a CLI-6 cartridge. It is, in fact, a BCI-6, as immediately spotted by

the eagle eyed contributors, so the name in the title and text has been changed accordingly.

cartridges cost a lot to buy new so I thought it would be interesting to see what goes into them and whether

it was possible to ponder on how much R & D went into their design. And to wonder whether cheaper copies

are as well made. Then I thought I'd photograph it and label what I found interesting:

There are three pieces of foam, not two. The small, oval shaped plug through which the ink is fed to the nozzles

is surprisingly rigid and not like the other two pieces at all:

The separator between the ink chamber and the foam chamber has a rectangular hole in the bottom to allow the

ink to feed through. This is where the needle goes when refilling with the 'German' method. Does anybody not

use this method nowadays?

Immediately above this hole, and on the side of the separator facing the foam chamber, are a number of grooves

which are recessed into the plate:

Here is a close up of the grooves:

And this is what they look like from the other side. Note that the recess stops below the top edge of the lower foam:

Now here's what, for me, is the really interesting part - the top plate. There are a number of 'prongs' which keep

the foam in place. There's a similar shaped 'prong' in the ink chamber side too which appears to serve no purpose

whatsoever. But do you see those two bulges which resemble hemispheres? They've not come out too clearly in

this photo (they are clearer in my first photo) but they are hollow, i.e. they're recessed from above but there's no

hole in them. It's like they are expansion chambers of some kind. I wonder what purpose they serve?

Now look at the top plate from above, with the label peeled off. Follow the path of the air channel groove from its

vent to atmosphere through to the bleed hole into the foam chamber. See how, before getting there, it goes from

the vent to atmosphere first through the left-hand hemispherical chamber, then out again, then through the

right-hand hemishperical chamber and out again before finally reaching the air bleed into the foam chamber.

And the path it follows is not the most obvious one. I'd love to know the science behind this and how it came to be

designed this way.

Anyway, I hope you found this as interesting as I did. I'm now using a Canon Pro9000 II which uses CLI-8 cartridges

but the design appears to be virtually identical, apart from the chip. To my mind it goes some way to explaining that

there's a lot more to an ink cartridge than one might, at first glance, think.

Paul

Edit: In the original post I inadvertently called this a CLI-6 cartridge. It is, in fact, a BCI-6, as immediately spotted by

the eagle eyed contributors, so the name in the title and text has been changed accordingly.