- Joined

- Nov 3, 2004

- Messages

- 3,143

- Reaction score

- 1,521

- Points

- 337

- Location

- Bay Area CA

- Printer Model

- CR-10, i560 ,MFC-7440N

As some of you know (*cough* @The Hat *cough*) I'm pretty impatient when it comes to my printing time.

Well, within weeks of getting my first 3D printer, I started seeing videos where people upgraded the default .4 mm nozzle to bigger ones. There are obviously tradeoffs for going bigger, but I always wanted to try it.

... that said, I was always scared to mess with the nozzle, heat-block, throat, and general hot-end of my printer. Knowing my luck with Murphy's law, the minute I mess with something that isn't broken... and try to make it better, is when things would go sideways.

So, for a year I didn't touch the hot end. Even though about 6 months ago I purchased this set of 10 different sized nozzles for my CR-10: https://amzn.to/2tnSpAL

... and so, they sat in my desk untested.

until today

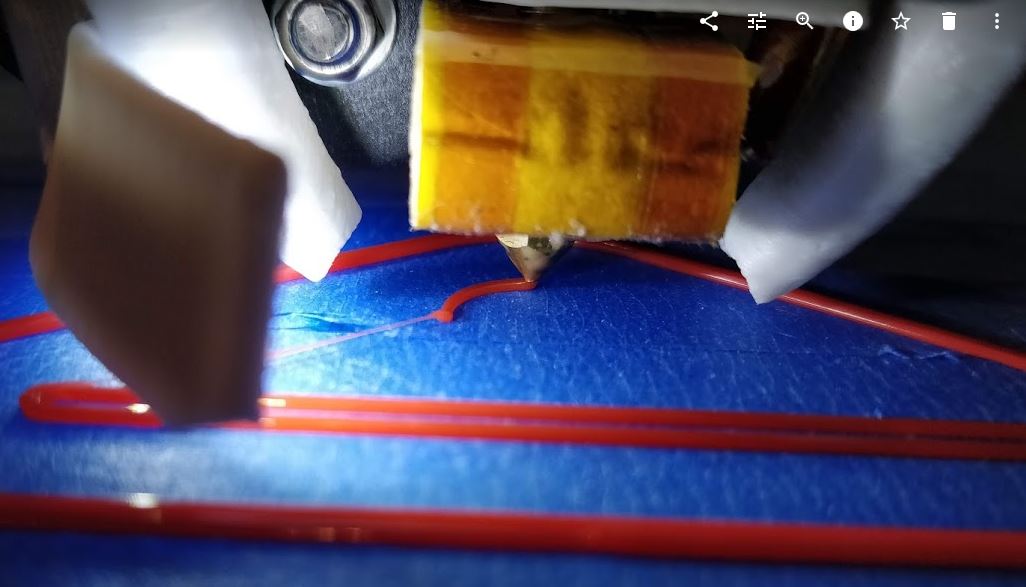

I followed the video instructions by heating up the hotend, pulling out the filament, securing the block with a wrench, and then removing the hot nozzle, and inserting the new one.

I went BIG for my first attempt and loaded up the 1mm nozzle!

Here's a pic of my tests using this thing (that I love to print): https://www.thingiverse.com/thing:867811

In order starting with the black print:

It was pretty entertaining... almost comical, using the 1.0 mm nozzle. The huge layer lines were just silly, and seeing the filament spool spin SUPER fast, and that thick bead of plastic exiting the nozzle was crazy!

Well, within weeks of getting my first 3D printer, I started seeing videos where people upgraded the default .4 mm nozzle to bigger ones. There are obviously tradeoffs for going bigger, but I always wanted to try it.

... that said, I was always scared to mess with the nozzle, heat-block, throat, and general hot-end of my printer. Knowing my luck with Murphy's law, the minute I mess with something that isn't broken... and try to make it better, is when things would go sideways.

So, for a year I didn't touch the hot end. Even though about 6 months ago I purchased this set of 10 different sized nozzles for my CR-10: https://amzn.to/2tnSpAL

... and so, they sat in my desk untested.

until today

I followed the video instructions by heating up the hotend, pulling out the filament, securing the block with a wrench, and then removing the hot nozzle, and inserting the new one.

I went BIG for my first attempt and loaded up the 1mm nozzle!

Here's a pic of my tests using this thing (that I love to print): https://www.thingiverse.com/thing:867811

In order starting with the black print:

- 0.4mm nozzle at .2mm layer height

- 1.0mm nozzle at .4mm layer height. It came out quite nice, except I only had one top layer

- 1.0mm nozzle at .7mm layer height.Similar to above

- 1.0mm nozzle at .9mm layer height. Ok, now this was just silly! I didn't obey the 80% of nozzle diameter to height ratio, so I didn't have great quality / adhesion, but I fixed the top layer (2 layers) and it came out nicer!

- 0.6mm nozzle at .4mm layer height. This worked great, so I decided to keep this nozzle in my printer for now.

It was pretty entertaining... almost comical, using the 1.0 mm nozzle. The huge layer lines were just silly, and seeing the filament spool spin SUPER fast, and that thick bead of plastic exiting the nozzle was crazy!