I am trying to solve the photo black (CLI-8BK) that I have for over 3 months. This is on my MP830.

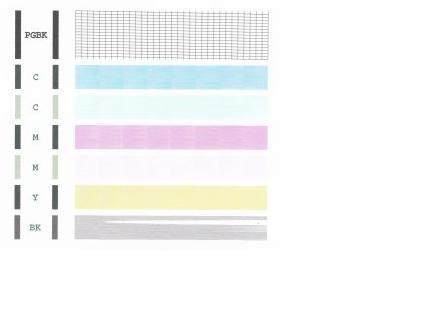

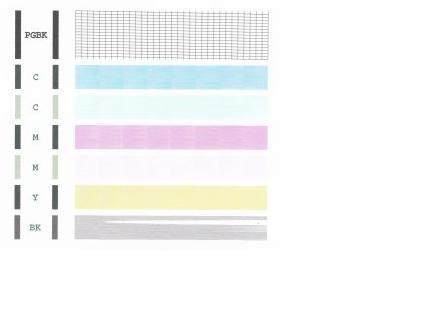

Doing a few cleaning cycles, with Windex on the inlet screen, will result a perfect nozzle check. But after printing a few pages, the nozzle check shows problem with the photo black.

I am using Canon OEM ink cartridges. I have switched the photo black cartridge from my iP4500. The result is the same.

I noticed that the photo black ink level did not go down at all after a few cleaning cycles. The chip on the photo black cartridge reports low ink level. But it still have a full tank of ink.

The purge unit is working fine. I flooded the right square pad with Windex. The Windex disappears after close/open the cover.

My observation:

1. I think the Windex dilutes the photo black ink when I put Windex on the inlet screen before doing cleaning cycles. This is the only way that I got a perfect nozzle check. After that, I can print over 20 perfect nozzle check in a row.

3. Is it possible that the purge tube is not connected to the bottom of square pad and the Windex just drained away?

Any suggestion on how to approach this problem.

Doing a few cleaning cycles, with Windex on the inlet screen, will result a perfect nozzle check. But after printing a few pages, the nozzle check shows problem with the photo black.

I am using Canon OEM ink cartridges. I have switched the photo black cartridge from my iP4500. The result is the same.

I noticed that the photo black ink level did not go down at all after a few cleaning cycles. The chip on the photo black cartridge reports low ink level. But it still have a full tank of ink.

The purge unit is working fine. I flooded the right square pad with Windex. The Windex disappears after close/open the cover.

My observation:

1. I think the Windex dilutes the photo black ink when I put Windex on the inlet screen before doing cleaning cycles. This is the only way that I got a perfect nozzle check. After that, I can print over 20 perfect nozzle check in a row.

2. The photo black nozzles are clogged badly because the cleaning cycles did not lower the photo black ink level.Trigger 37 said in other thread that the nozzle may hold enough ink to print 30 nozzle check.

3. Is it possible that the purge tube is not connected to the bottom of square pad and the Windex just drained away?

Any suggestion on how to approach this problem.