RogerB

Print Addict

- Joined

- Sep 27, 2010

- Messages

- 293

- Reaction score

- 315

- Points

- 183

- Location

- S.E. England

- Printer Model

- Epson Pro3880

At the beginning of April this year I started light fade tests to see how some 3rd-party inks for the Epson Pro3800 compared to the OEM ink. Out of interest I also included a couple of OEM dye inks from Epson and Canon. The test samples were placed in a south-facing window and have been there now for 4 months. I have not attempted to measure or control the light exposure so I cannot compare my results to other peoples results.

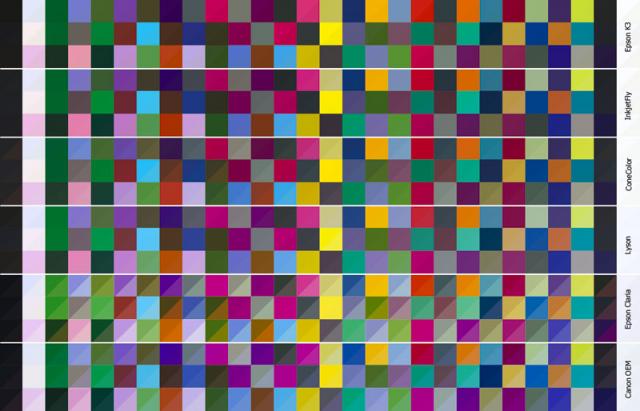

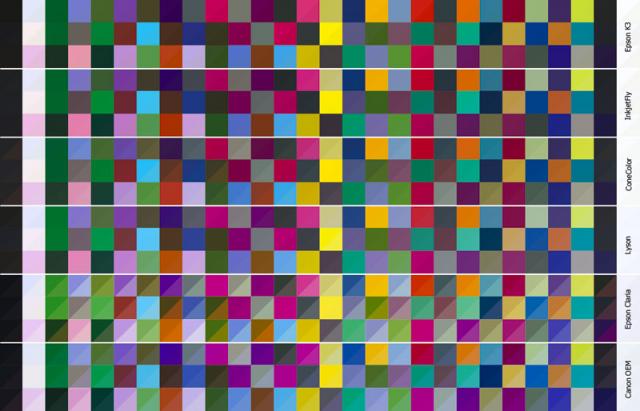

The test sample for each ink/paper combination is a section of the Gretag-Macbeth TC918 profiling target. I have used the first three rows of the target which gives 51 colour patches. The patches are measured three times using an i1Pro and the measurements averaged. I then convert the measurements to real images (TIFF) using the LOGO ColorLab utility and import them into CS5. Using this method the colours are quite accurate.

By masking the patches of the original measurement and overlaying it on the latest measurements I get the image shown below. Each colour patch is divided diagonally, with the top left section showing the original colour and the bottom right showing the colour after light exposure. I feel that this method provides the best of both worlds, since the numeric data is embedded in the image and the visual change can be seen very clearly. Unfortunately the severe compression of the JPEG here has introduced some nasty artefacts, but the general effect can still be seen. I will post a high resolution version on my web site soon for anyone who is interested.

What is immediately obvious, and not really surprising, is that the two OEM dye inks are fading more quickly than the pigment types. What is surprising, to me at least, is that the Epson Claria is fading much more quickly that the Canon. This may well be because of the paper used. The Claria is printed on 7dayshop gloss paper (an "own brand" UK paper) while the Canon is on Canon paper.

Of the pigment samples, the first three are printed on Harman Gloss Baryta since this is my paper of choice. The Lyson ink is on Epson Premium Gloss. What surprises me here is that the Epson K3 ink seems to be fading slightly faster than the 3rd-party inks. The least fading is exhibited by the Lyson, followed by the IJF and then the ConeColor. All seem to be fading less than the Epson overall. There are visible differences in fading of different colours for different inks, so different images may fare better with some inks than with others. Confusing? Yes!

I am not trying to draw any definite conclusions from this. What does reassure me is that the 3rd-party inks are standing up very well on the paper that I chose to use for my "serious" work. Taking a different view, I ask myself if I would see any difference in a real print after the same light exposure. I suspect that all but the Epson Claria would still be acceptable, some might even say "identical to the original", but the Claria on this particular paper would probably be noticeably degraded.

I will be writing this up more fully at a later date, but thought that I would share these preliminary findings straight away.

The test sample for each ink/paper combination is a section of the Gretag-Macbeth TC918 profiling target. I have used the first three rows of the target which gives 51 colour patches. The patches are measured three times using an i1Pro and the measurements averaged. I then convert the measurements to real images (TIFF) using the LOGO ColorLab utility and import them into CS5. Using this method the colours are quite accurate.

By masking the patches of the original measurement and overlaying it on the latest measurements I get the image shown below. Each colour patch is divided diagonally, with the top left section showing the original colour and the bottom right showing the colour after light exposure. I feel that this method provides the best of both worlds, since the numeric data is embedded in the image and the visual change can be seen very clearly. Unfortunately the severe compression of the JPEG here has introduced some nasty artefacts, but the general effect can still be seen. I will post a high resolution version on my web site soon for anyone who is interested.

What is immediately obvious, and not really surprising, is that the two OEM dye inks are fading more quickly than the pigment types. What is surprising, to me at least, is that the Epson Claria is fading much more quickly that the Canon. This may well be because of the paper used. The Claria is printed on 7dayshop gloss paper (an "own brand" UK paper) while the Canon is on Canon paper.

Of the pigment samples, the first three are printed on Harman Gloss Baryta since this is my paper of choice. The Lyson ink is on Epson Premium Gloss. What surprises me here is that the Epson K3 ink seems to be fading slightly faster than the 3rd-party inks. The least fading is exhibited by the Lyson, followed by the IJF and then the ConeColor. All seem to be fading less than the Epson overall. There are visible differences in fading of different colours for different inks, so different images may fare better with some inks than with others. Confusing? Yes!

I am not trying to draw any definite conclusions from this. What does reassure me is that the 3rd-party inks are standing up very well on the paper that I chose to use for my "serious" work. Taking a different view, I ask myself if I would see any difference in a real print after the same light exposure. I suspect that all but the Epson Claria would still be acceptable, some might even say "identical to the original", but the Claria on this particular paper would probably be noticeably degraded.

I will be writing this up more fully at a later date, but thought that I would share these preliminary findings straight away.