Redbrickman

Printer Master

- Joined

- Dec 27, 2010

- Messages

- 1,162

- Reaction score

- 1,279

- Points

- 293

- Location

- UK

- Printer Model

- Brother MFC-L8690-CDW

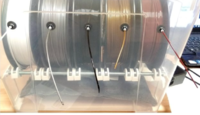

This looks like a well thought out and neat solution if you are having problems with moisture...

https://www.thingiverse.com/thing:2873244/

https://www.thingiverse.com/thing:2873244/