Tom Hock

Getting Fingers Dirty

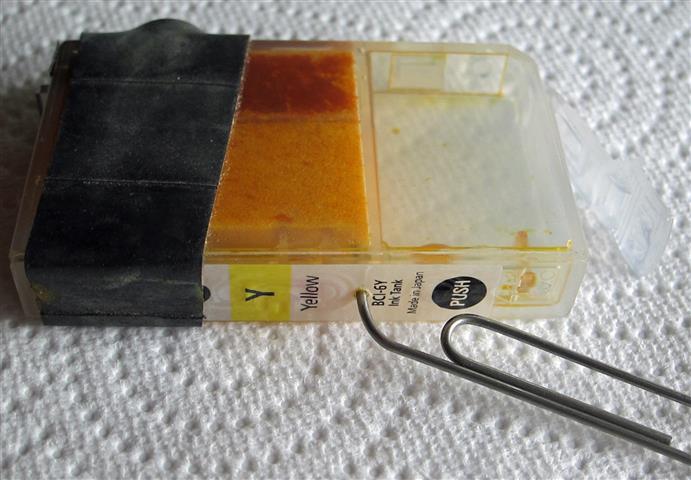

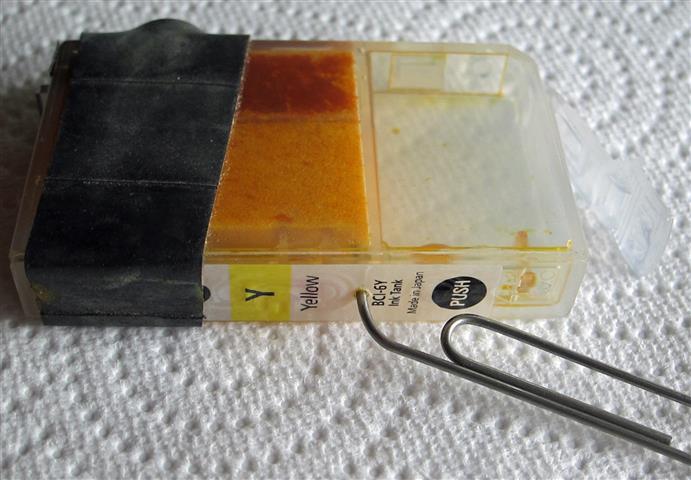

Canon ink tank vent on clear tanks #3, #5, #6, #8 and maybe others.

Sometimes when using the German refill method the syringe needle will push the sponge tightly against the surface that separates the ink chamber from the sponge chamber and into the vent path along this wall leading to the top serpentine vent area. This can block the air flow and prevent the ink from flowing into the sponge, resulting in ink starvation, poor printing and maybe print head failure.

This doesnt happen often, and when it does, if it is noticed, the suggested fix is to tap the ink tank on a hard surface with the sponge side down in hopes of causing the sponge to move away from the vent path. Proper venting is critical, and this method seems hit-or-miss.

I may have a better method as shown in the pictures. By drilling a 1/16 inch hole in the top of the tank just inside the sponge chamber, a wire, or the syringe needle can be feed along this vent wall to move the sponge away to insure proper venting, which is essential. This hole can be sealed with tape so as not to interfere with the serpentine vent structure.

During the next few months I will be using tanks that I have tried this method on, but It looks good on paper so I thought I would pass it on for your critique.

Sometimes when using the German refill method the syringe needle will push the sponge tightly against the surface that separates the ink chamber from the sponge chamber and into the vent path along this wall leading to the top serpentine vent area. This can block the air flow and prevent the ink from flowing into the sponge, resulting in ink starvation, poor printing and maybe print head failure.

This doesnt happen often, and when it does, if it is noticed, the suggested fix is to tap the ink tank on a hard surface with the sponge side down in hopes of causing the sponge to move away from the vent path. Proper venting is critical, and this method seems hit-or-miss.

I may have a better method as shown in the pictures. By drilling a 1/16 inch hole in the top of the tank just inside the sponge chamber, a wire, or the syringe needle can be feed along this vent wall to move the sponge away to insure proper venting, which is essential. This hole can be sealed with tape so as not to interfere with the serpentine vent structure.

During the next few months I will be using tanks that I have tried this method on, but It looks good on paper so I thought I would pass it on for your critique.