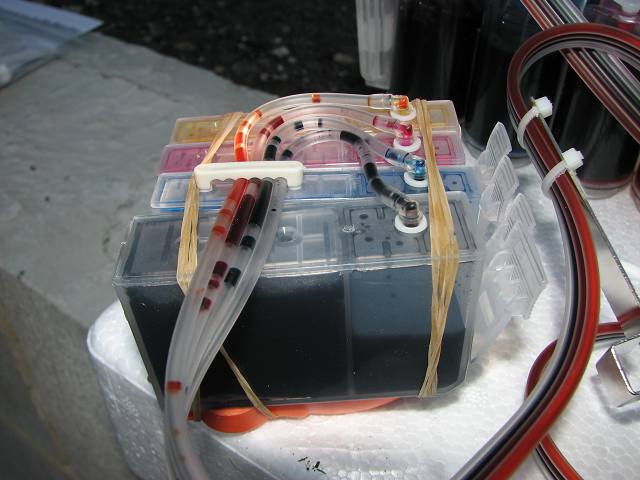

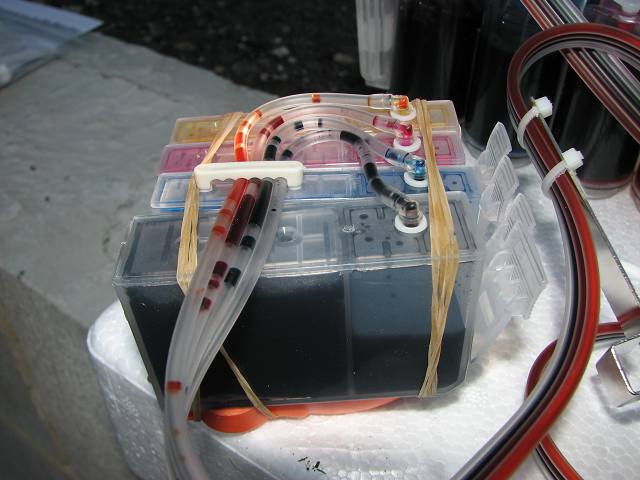

Here's some pictures of a CISS for the Canon IP3000 that I have just purchased from www.selectiveimage.com.au

The unit comes well boxed. The manual is made by a non native english speaker.

The tanks are see thru and have a main plug for refilling and a smaller hole for air filter ( not fitted in the photo)

At one end is a handy pinch roller to clamp of the tubes.

The cartridges are similar to OEM in design with the tube connected over the non sponged compartment with a push fit elbow. There is a neat modular bar to hold the tubes in place. Also the exit port clips twist off, but can be put back on the exit port and twisted so they lock in place - resealing the exit port - I haven't seen this feature before.

The silastic seals that are placed in the base of the print are provided pre-cut.

There is an arm attachment to support the tubes that uses double sided tape to attach.

The cartridges are now in place.

This is the path of the tubes when installed in the printer.

I did have to make a cut in the lid with my dremel to get the lid to close.

Also comes with some syringes/ needles and double sided adhesive and spare elbows and silastic sleeves.

No problems with operation of the unit so far. The retailer provides prompt email support.

The unit comes well boxed. The manual is made by a non native english speaker.

The tanks are see thru and have a main plug for refilling and a smaller hole for air filter ( not fitted in the photo)

At one end is a handy pinch roller to clamp of the tubes.

The cartridges are similar to OEM in design with the tube connected over the non sponged compartment with a push fit elbow. There is a neat modular bar to hold the tubes in place. Also the exit port clips twist off, but can be put back on the exit port and twisted so they lock in place - resealing the exit port - I haven't seen this feature before.

The silastic seals that are placed in the base of the print are provided pre-cut.

There is an arm attachment to support the tubes that uses double sided tape to attach.

The cartridges are now in place.

This is the path of the tubes when installed in the printer.

I did have to make a cut in the lid with my dremel to get the lid to close.

Also comes with some syringes/ needles and double sided adhesive and spare elbows and silastic sleeves.

No problems with operation of the unit so far. The retailer provides prompt email support.