- Joined

- Jan 18, 2010

- Messages

- 15,789

- Reaction score

- 8,819

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

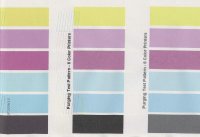

The top CISS system works (Simple answer) because the tubing does not go all the way to the bottom of the tank so therefore no settlement can take place and clog the suspended tubing; it’s primed by pulling a vacuum on the tubing till the ink starts to flow.

The only way you can stop a Marrutt CISS from clogging up when used with pigment ink is to use it heavily every day other that that is will eventfully clog up which would require a complete flush of the whole system..

The only way you can stop a Marrutt CISS from clogging up when used with pigment ink is to use it heavily every day other that that is will eventfully clog up which would require a complete flush of the whole system..

.

.