is likely one of the better cleaning tools I have used for declogging heads such as yours. I ran into a similar issue with my Pro9000, since it had sat for months without use.

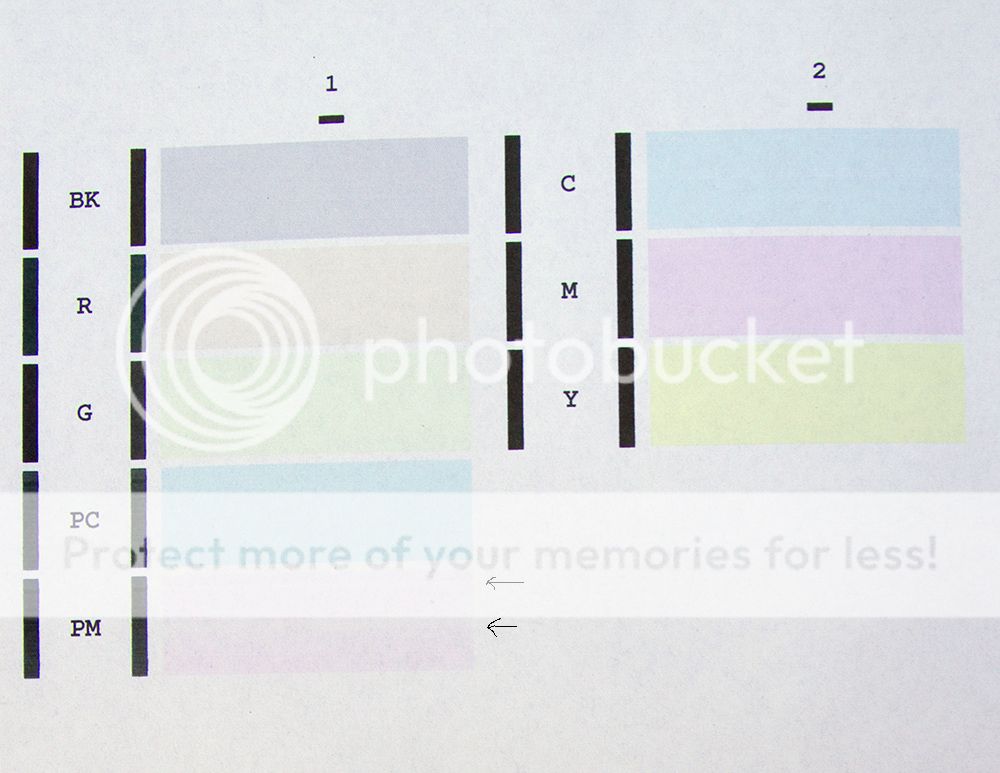

I had to use the tool shown above to clean it. I also used it to revive an iP3000 that was given to me. The magenta channel was practically hardly printing but now is perfect.

Here are a few warning about using such a tool. I am very careful when pressurizing the head because the printhead nozzle plate is actually glued over a ceramic substrate that is actually an inkwell/trough behind the line of nozzles. if you pressurize it too much, you can delaminate nozzle plate from the ceramic. The result will be ink crossover between adjacent channels. I prefer using a suction with higher pressure if needed. When I cleared the head from the iP3000, I used a number of back and forth cycles to literally scrub the nozzle heaters.

How to make such a contraption: All things needed are available from a well equipped aquarium store. The green tubing is flexible air hose line...the soft rubber type. Now you can attach that to the tip of the syringe and try to attach the other end to the printhead inlet with the rubber washer removed. If your hands are kinda clumsy, it will take some wrangling. To make it easier, you want a rigid attachment to hold onto while trying to fit it onto the inlet. The aquarium store has such an item. They will carry a rigid 3/16" line. that fits into the airline tubing. This allows coupling or joining the tubing as well. Well, all you need then is to cut about 3/4" length of soft tubing. This will be placed at the end of the rigid line, leaving about 1/4" of the soft tubing exposed. This exposed end will then be attached to the inlet. You can leave whatever length of rigid tubing that you like and then put some airline tubing over that end and attach the syringe.

Now here's the good part. If you leave the attachment on the inlet, you can place windex into the column and just let gravity pull the windex through the printhead without using a head cleaning routine. This gently cleans the printhead out with no risk of over pressure. If you want more capacity use a syringe to flow 10cc slowly though the printhead.

It's worked for me, hope it does the same for you.