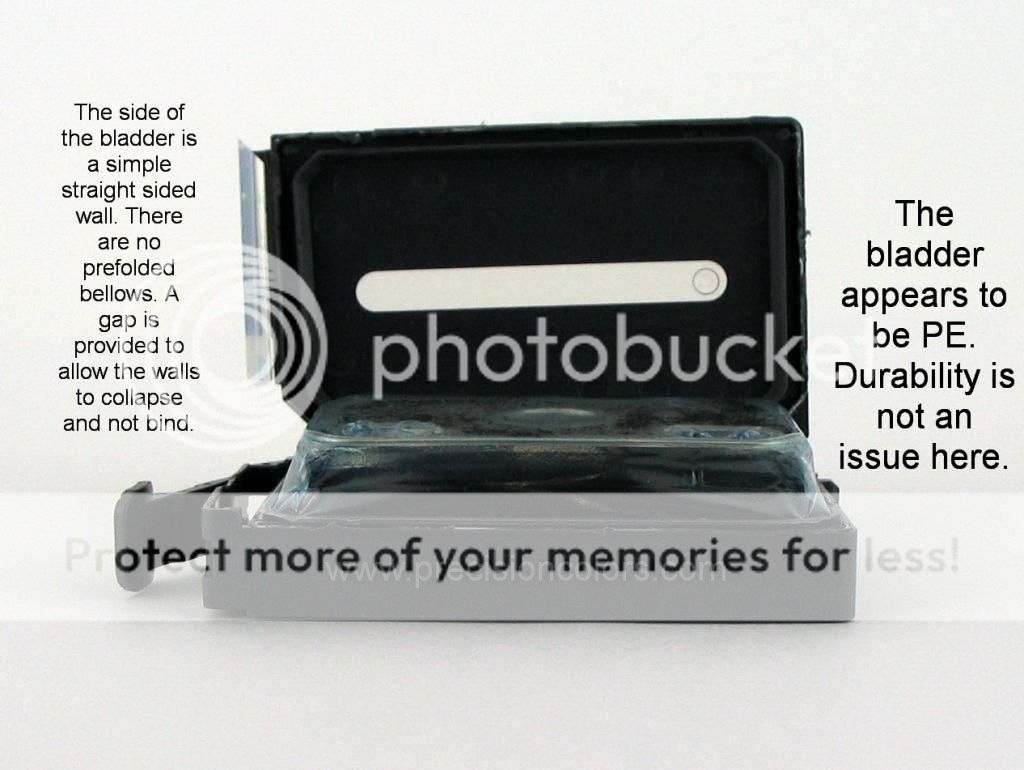

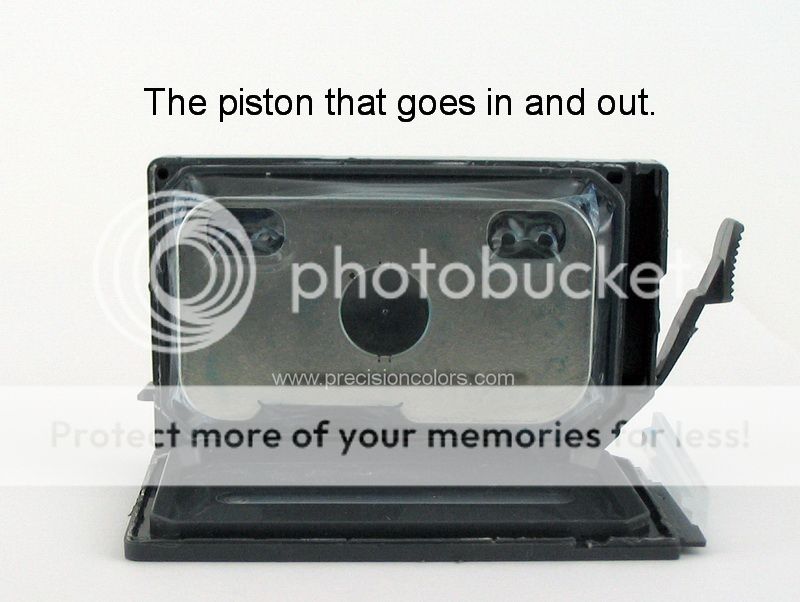

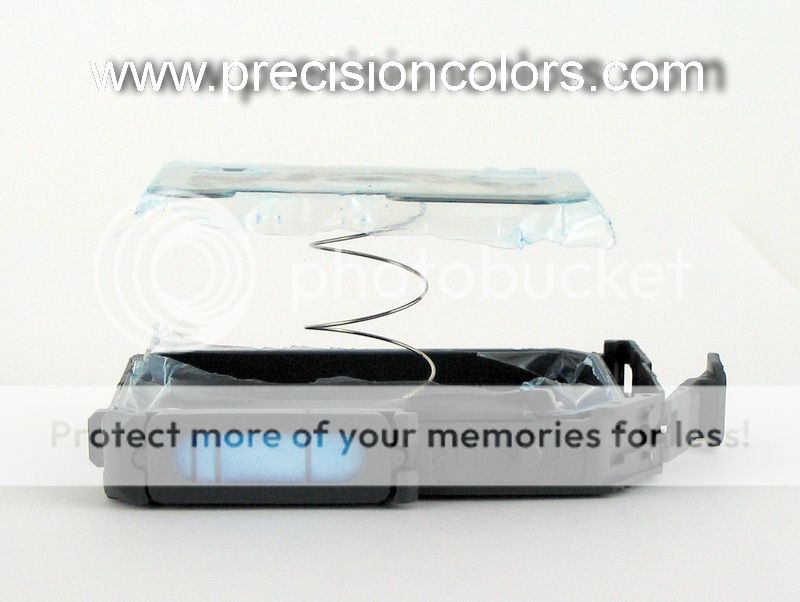

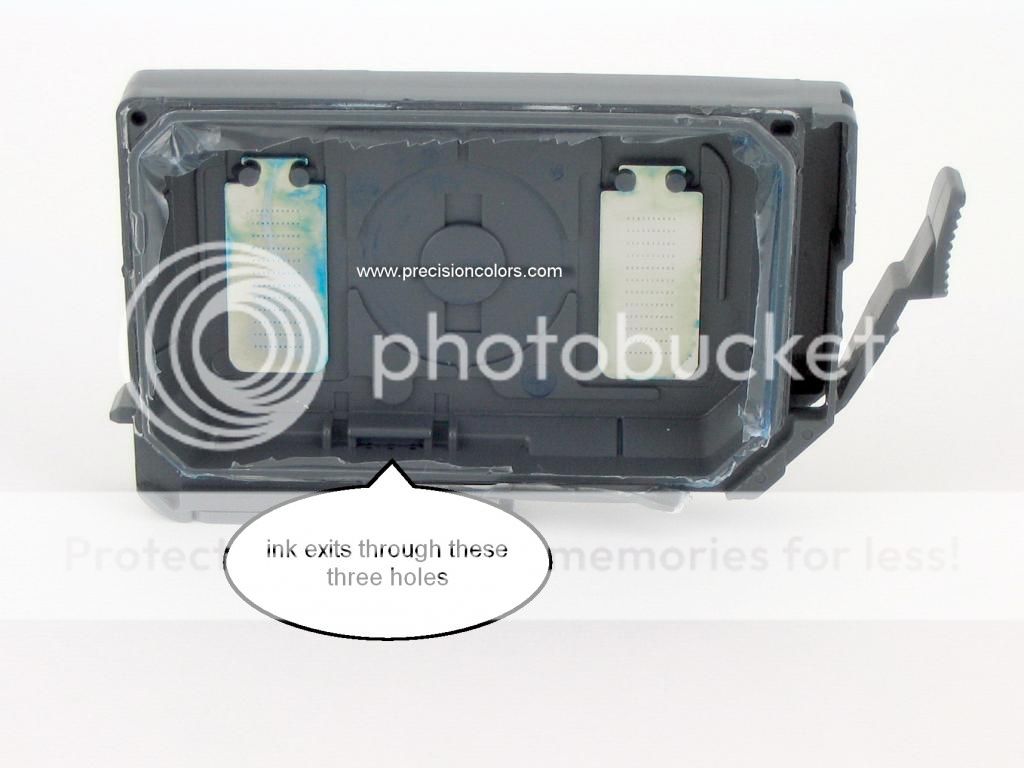

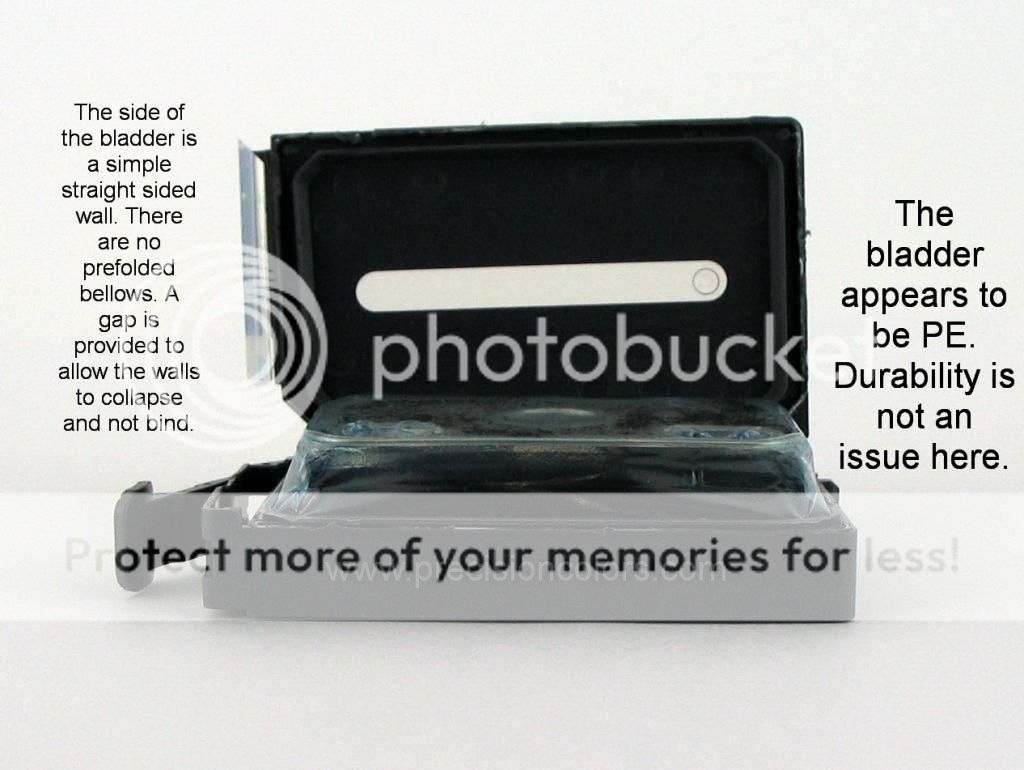

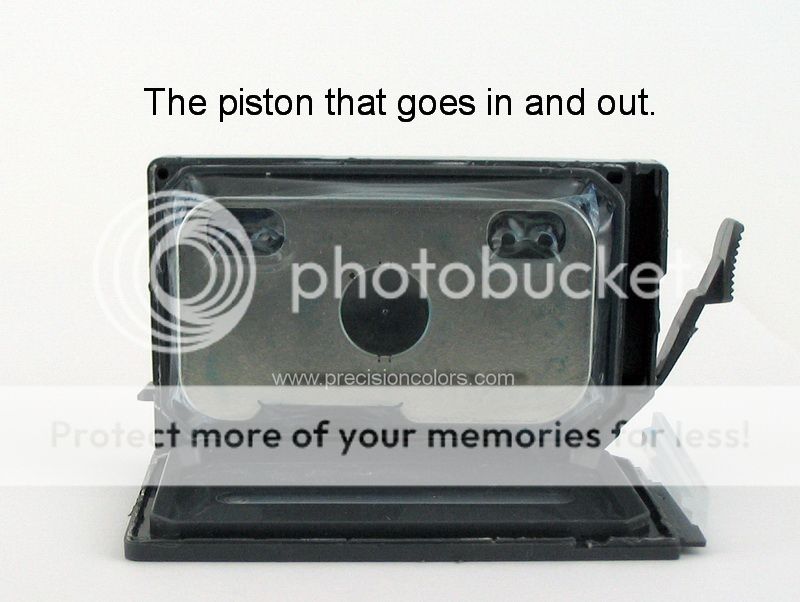

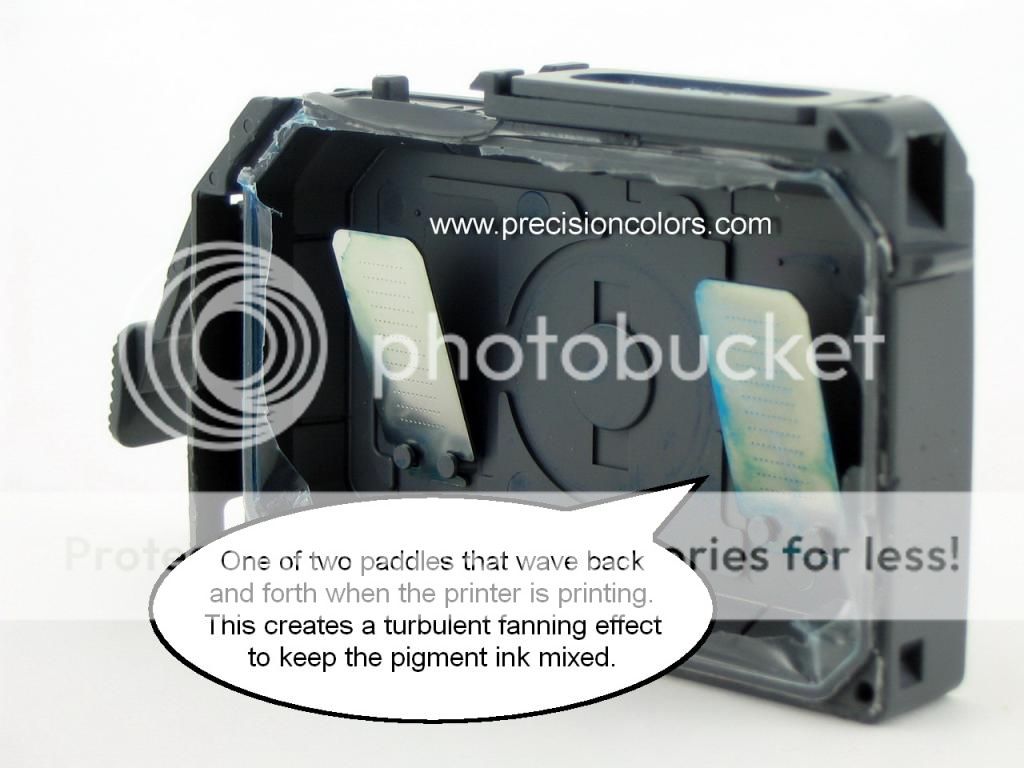

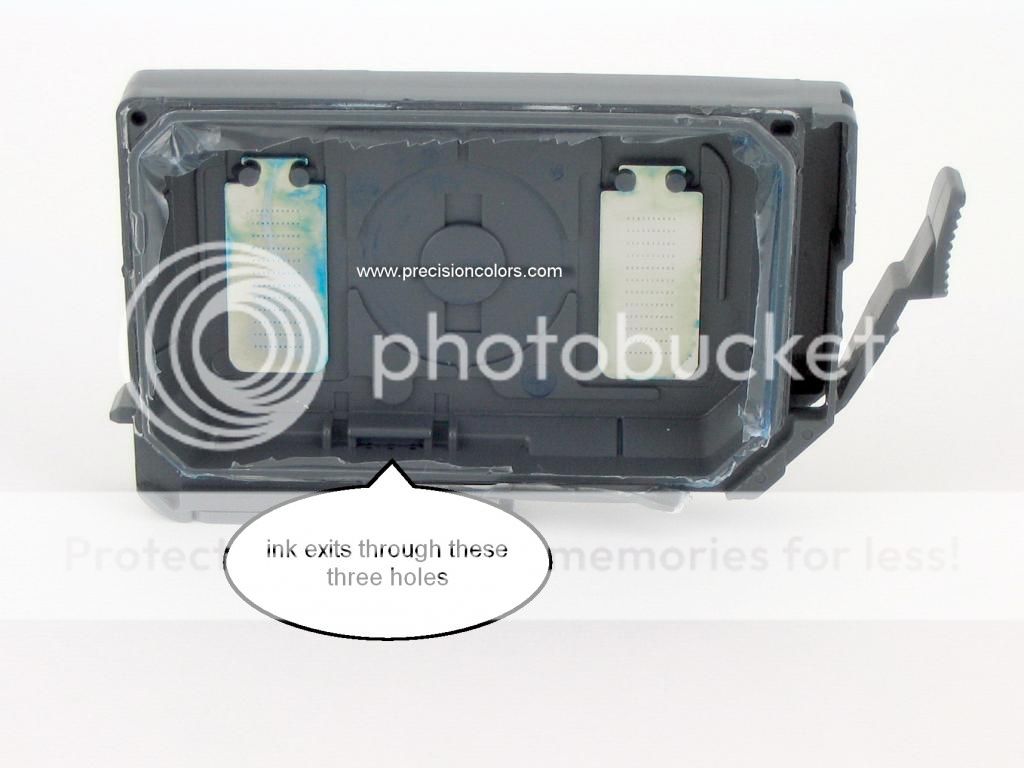

The following are the internals of the PGI-9 Cartridge. The viewer will come to realize that while simple to refill, there are a number of refinements built into the cartridge which many will never realize are there. Furthermore, these refinements are there for a purpose and ignoring the issues that Canon engineers knew about and how they came about their solutions will possibly lead to faulty refill processes and procedures with eventual detriment to the printer.

View for your own pleasure.

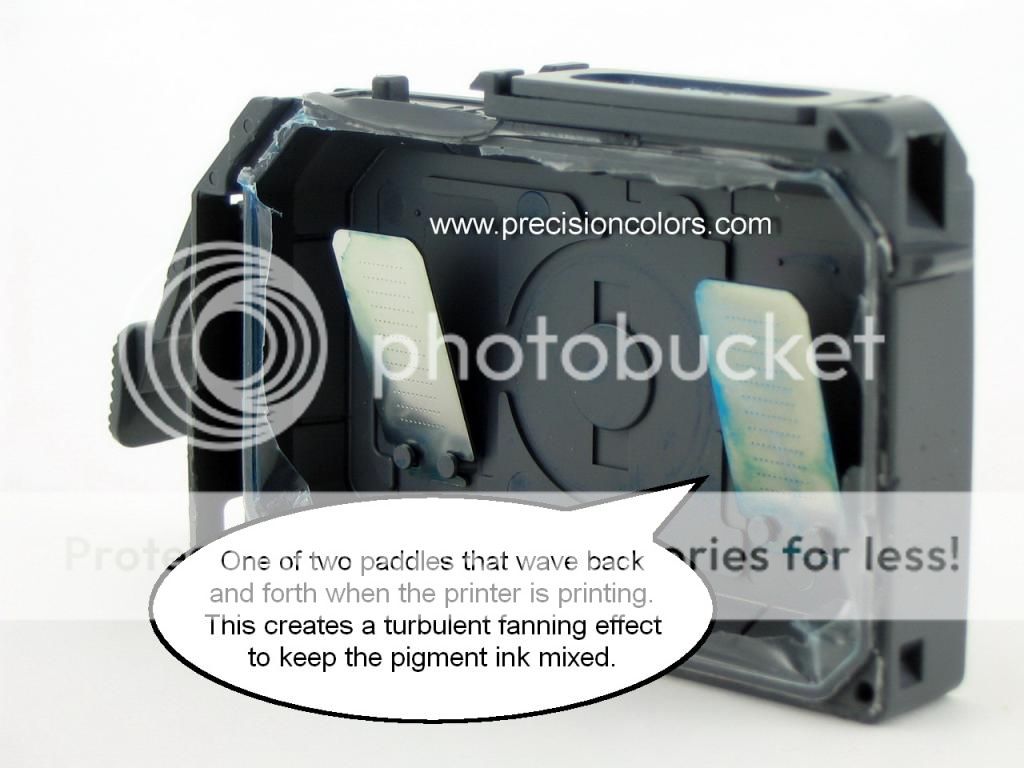

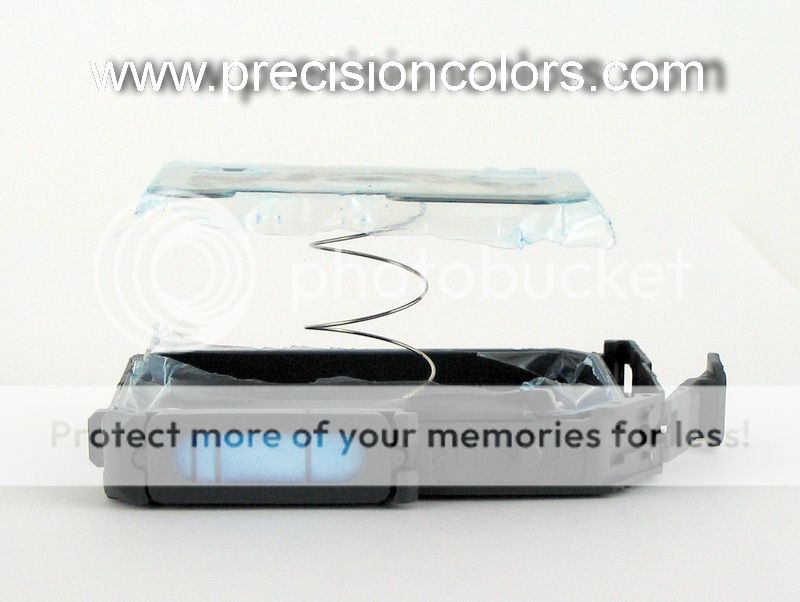

Finally, did you notice the small serrations in the paddles !!??? They are there for a reason. The number of details that you simply will never see.

View for your own pleasure.

Finally, did you notice the small serrations in the paddles !!??? They are there for a reason. The number of details that you simply will never see.