- Joined

- Jan 18, 2010

- Messages

- 15,972

- Reaction score

- 8,962

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

I have filled my PGI-9 cartridges more than a dozen times now and never felt purging was an issue with these cartridges.

Theres nothing inside them to prevent ink flowing so I taught till one of them started to have about 50% reduced flow rate.

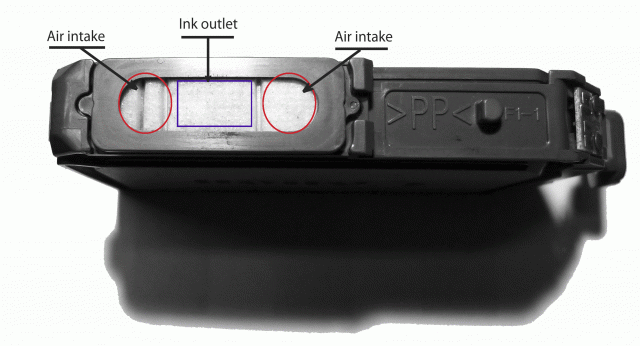

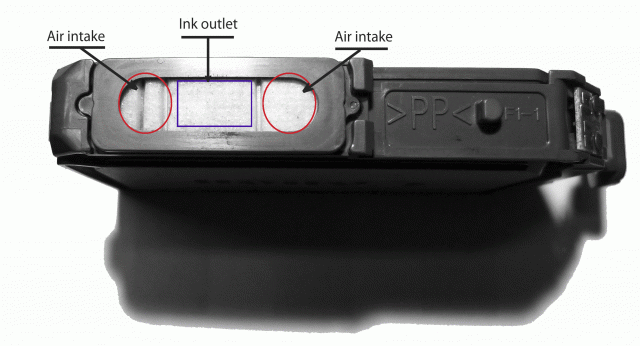

There is a very small thin sponge like material in the outlet hole to allow ink out to the print head and air back in which is vital in this type cartridges.

I suspect that the air flow was being obstructed by foreign bodys of some sort which may have caused my poorer than expect print quality, Mikling mention something about the air passage in these cartridges before a good while ago and I didnt quite take it all in.

A quick rinse in soapy water followed by clean water and the cartridge was back as good as it ever was, from now on any of my carts that need refilling will first get a refreshing bath before going back into service.

When I originally decided to refill every cartridge that I used, I never imagined for one moment just how much of a learning curve it all has been and continues to be,

but I have to say that OEM cartridges are just magic..

Here is a shot of the bottom of the cartridge.

Theres nothing inside them to prevent ink flowing so I taught till one of them started to have about 50% reduced flow rate.

There is a very small thin sponge like material in the outlet hole to allow ink out to the print head and air back in which is vital in this type cartridges.

I suspect that the air flow was being obstructed by foreign bodys of some sort which may have caused my poorer than expect print quality, Mikling mention something about the air passage in these cartridges before a good while ago and I didnt quite take it all in.

A quick rinse in soapy water followed by clean water and the cartridge was back as good as it ever was, from now on any of my carts that need refilling will first get a refreshing bath before going back into service.

When I originally decided to refill every cartridge that I used, I never imagined for one moment just how much of a learning curve it all has been and continues to be,

but I have to say that OEM cartridges are just magic..

Here is a shot of the bottom of the cartridge.