chaos_engineer

Getting Fingers Dirty

- Joined

- Jun 19, 2023

- Messages

- 26

- Reaction score

- 36

- Points

- 38

- Printer Model

- Anycubic Photon Mono 4k

I've had a Monoprice Voxel/Flashforge Adventurer 3 for a few months that was gifted to me by a buddy. Great printer, but it was slow and really only liked PLA. So I've been kinda looking for a faster upgrade that could handle other filament types. Found a great deal the on the Adventurer 5M (299USD Amazon Prime deal) and jumped on it.

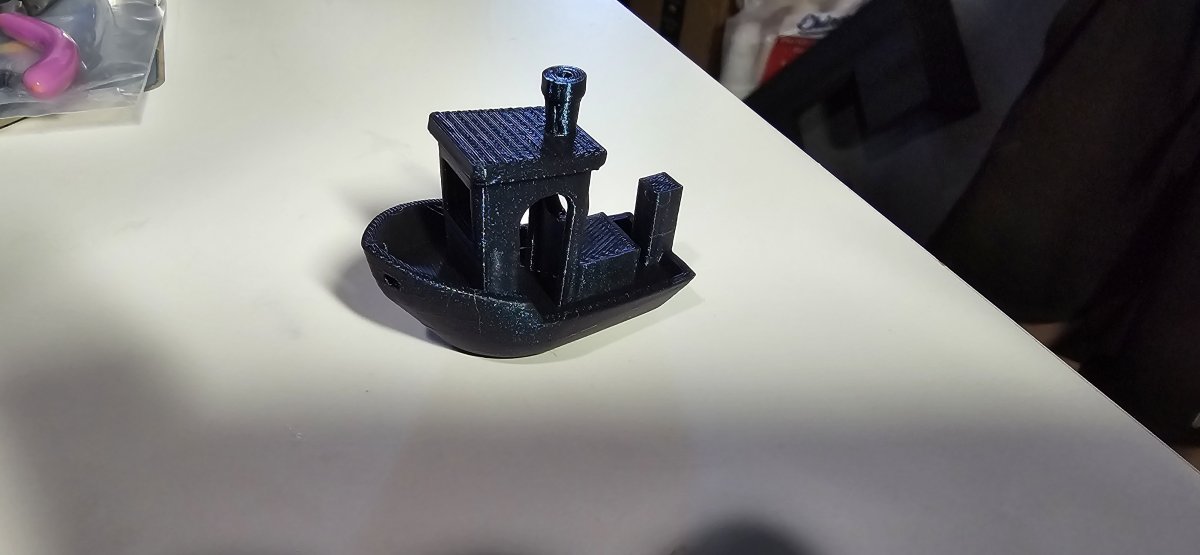

Setup was a breeze, I had it out, leveled, and printing in about 15 minutes from delivery. Here's the first benchy, which took 14 minutes.

Quick vid in action. Real time.

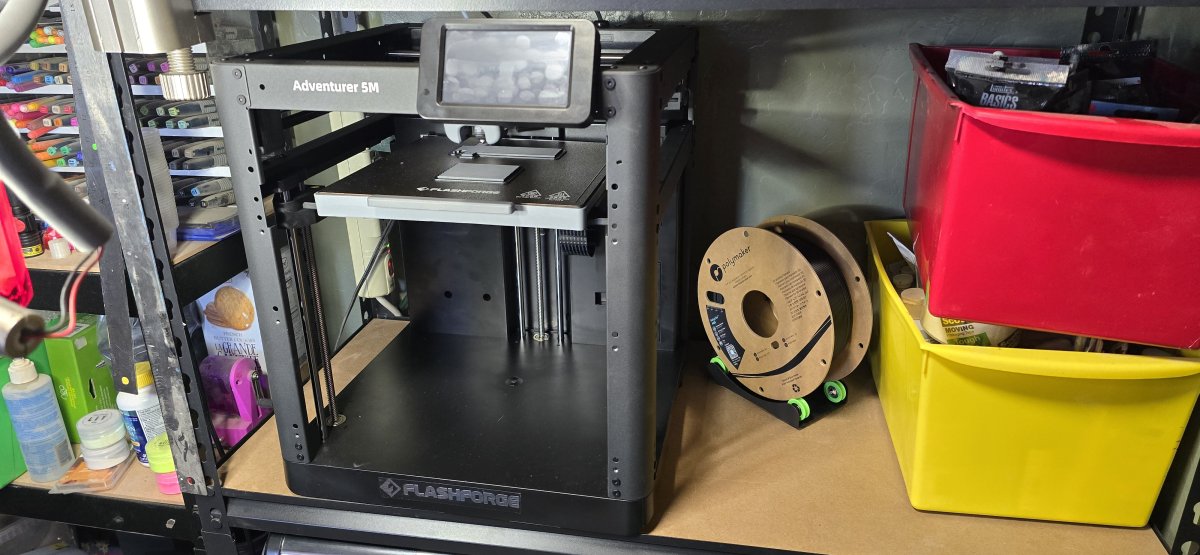

Today it moved to it's permanent home. First mod is to relocate the spool holder from the rear to the side. Running that now, and also testing ABS. So far, so good.

it's a lot louder than the voxel, but I can quiet it down if I enclose it.

I'll post some periodic updates as I live with it and see how I feel over time.

Setup was a breeze, I had it out, leveled, and printing in about 15 minutes from delivery. Here's the first benchy, which took 14 minutes.

Quick vid in action. Real time.

Today it moved to it's permanent home. First mod is to relocate the spool holder from the rear to the side. Running that now, and also testing ABS. So far, so good.

it's a lot louder than the voxel, but I can quiet it down if I enclose it.

I'll post some periodic updates as I live with it and see how I feel over time.