imbaine13

Print Lurker

- Joined

- Jun 7, 2019

- Messages

- 3

- Reaction score

- 0

- Points

- 2

- Printer Model

- HP 2130

Hello everyone,

I want to remove the sponge from a black HP 123 cart, and make it spongeless.

Something similar to this https://www.bchtechnologies.com/mod...1-62-63-64-65-66-67-68-69-70-as-rfc-hpsq.html except without their kit.

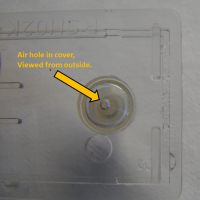

I have tried to find a way to prevent ink leaking from the print head, but all in vain. When i make the cart air tight, it doesn't leak, but it also wont print. Can I get some kind of valve i could use that will prevent air flowing in and ink leaking out when the cart is not printing, but allow the air in when it's printing?

Appreciate any input, thanks!

Cheers,

Isaac.

I want to remove the sponge from a black HP 123 cart, and make it spongeless.

Something similar to this https://www.bchtechnologies.com/mod...1-62-63-64-65-66-67-68-69-70-as-rfc-hpsq.html except without their kit.

I have tried to find a way to prevent ink leaking from the print head, but all in vain. When i make the cart air tight, it doesn't leak, but it also wont print. Can I get some kind of valve i could use that will prevent air flowing in and ink leaking out when the cart is not printing, but allow the air in when it's printing?

Appreciate any input, thanks!

Cheers,

Isaac.