sneezer2

Getting Fingers Dirty

- Joined

- Jul 31, 2009

- Messages

- 79

- Reaction score

- 10

- Points

- 36

- Location

- USA Pennsylvania

- Printer Model

- mp610

First of all, yes, I am aware this printhead has been superseded by QY6-0075. Not sure what the

difference is but anyway this one was found in a used mp610 that I bought about a week ago.

First date of service (from the Eeprom dump) was Aug. 2013. Total pages printed 855. So,

except what you will see following, it should be a nice clean printer and it does appear to be so.

Of course the nozzle check on acquisition was awful but after a thorough cleaning all the CLI-8

checks are very good, so I don't show them here.

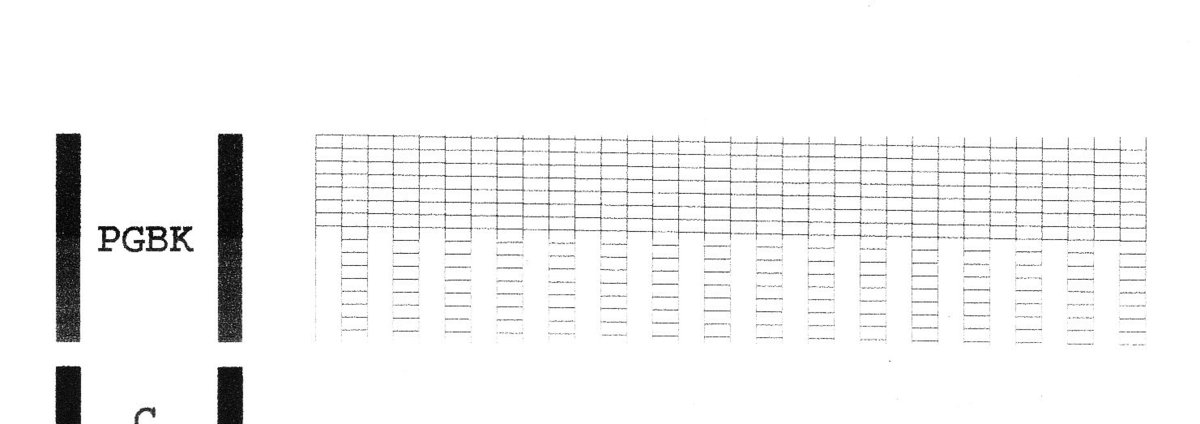

This is the PGBK check after cleaning. Exactly the same as before I brought the machine home.

Although I have never seen this pattern before, I suppose many of you have, so I submit it for

your diagnosis. My "conjecture" though is that somebody blew a few resistors by trying to

print some text off a dry cartridge.

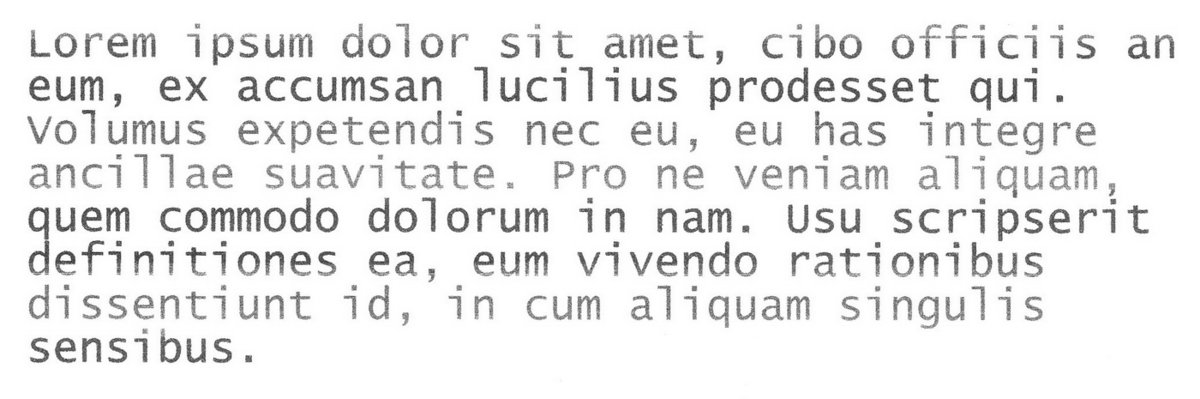

Now, here is the next curiosity. Printing from Windows notepad (and I am assuming this is done

automatically from the PGBK) the print quality is not good but could be considered at least

acceptable under not very rigorous criteria:

All the lettters are at least fully formed but some (line by line) appear lighter than others. Well,

I never knew and never asked what Canon was doing with all those nozzles but this reveals a

little something.

So I guess I could keep this and use it occasionally as a backup but my final question for some of

the experts would be what you think my chances are if I put in another print head (maybe new,

maybe not).

difference is but anyway this one was found in a used mp610 that I bought about a week ago.

First date of service (from the Eeprom dump) was Aug. 2013. Total pages printed 855. So,

except what you will see following, it should be a nice clean printer and it does appear to be so.

Of course the nozzle check on acquisition was awful but after a thorough cleaning all the CLI-8

checks are very good, so I don't show them here.

This is the PGBK check after cleaning. Exactly the same as before I brought the machine home.

Although I have never seen this pattern before, I suppose many of you have, so I submit it for

your diagnosis. My "conjecture" though is that somebody blew a few resistors by trying to

print some text off a dry cartridge.

Now, here is the next curiosity. Printing from Windows notepad (and I am assuming this is done

automatically from the PGBK) the print quality is not good but could be considered at least

acceptable under not very rigorous criteria:

All the lettters are at least fully formed but some (line by line) appear lighter than others. Well,

I never knew and never asked what Canon was doing with all those nozzles but this reveals a

little something.

So I guess I could keep this and use it occasionally as a backup but my final question for some of

the experts would be what you think my chances are if I put in another print head (maybe new,

maybe not).