- Joined

- Jan 18, 2010

- Messages

- 15,626

- Reaction score

- 8,696

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

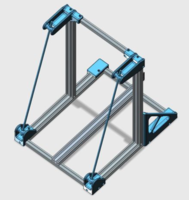

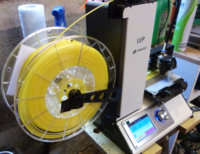

I have added a few more little extras to my Mini MS, the new spinner was supposed to be a bit smaller but who’s complaining, and I also got me a filament holder for the side of the printer, this has the reel pointing in the feed direction, just all great fun..

click to enlarge...

click to enlarge...

P.S. I have also relocated the printer to my work shed...

click to enlarge...

click to enlarge...P.S. I have also relocated the printer to my work shed...