- Joined

- Jan 18, 2010

- Messages

- 15,623

- Reaction score

- 8,695

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

I’ve been busy making a few more thing to improve my printers, I needed a new Fang because the current one got a thump after I burned my hand while working on the hot-end and it then developed a huge crack in the casing and is now wobbling all over the place.

I will also be raising the extruder motor a bit higher to bring the tubing feeding the hot-end level and that should help make feeding the filament a lot smoother. (That will be later)

I am currently waiting on some other pieces to come in from China and when I get them, I’ll put it together, most upgrades I make and install work but not always, but its still fun seeing what works and what doesn’t.

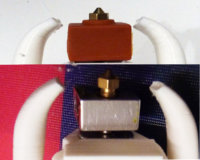

Here is a piece I made in SCAD to accommodate a new Turbo fan I want to use on the top of my new revised Fang, it took a bit of time, but I got there in the end, the only problem I encountered was figuring out how to hold this piece to the top of the Fang.

click to enlarge.

click to enlarge.

After studying it for a while I put four slots in the base and used cables ties in place of the screws, now it will all depend on @Redbrickman advice as to how I wire up this beast of a fan...

I can’t give credit to the originator of the Fang because I don’t which one I’m using, but thank to him anyway, I also made a few changes to his design to help remove the Pneumatic Connector when you get a blockage...

...

...

I will also be raising the extruder motor a bit higher to bring the tubing feeding the hot-end level and that should help make feeding the filament a lot smoother. (That will be later)

I am currently waiting on some other pieces to come in from China and when I get them, I’ll put it together, most upgrades I make and install work but not always, but its still fun seeing what works and what doesn’t.

Here is a piece I made in SCAD to accommodate a new Turbo fan I want to use on the top of my new revised Fang, it took a bit of time, but I got there in the end, the only problem I encountered was figuring out how to hold this piece to the top of the Fang.

click to enlarge.

click to enlarge.After studying it for a while I put four slots in the base and used cables ties in place of the screws, now it will all depend on @Redbrickman advice as to how I wire up this beast of a fan...

I can’t give credit to the originator of the Fang because I don’t which one I’m using, but thank to him anyway, I also made a few changes to his design to help remove the Pneumatic Connector when you get a blockage...

...

...