- Thread starter

- #51

- Joined

- Nov 3, 2004

- Messages

- 3,046

- Reaction score

- 1,405

- Points

- 337

- Location

- Bay Area CA

- Printer Model

- CR-10, i560 ,MFC-7440N

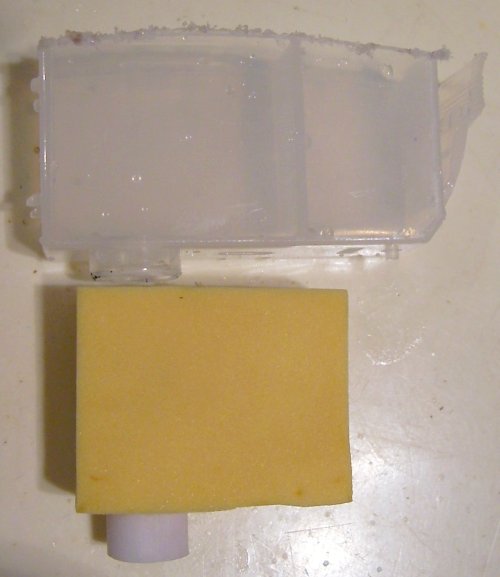

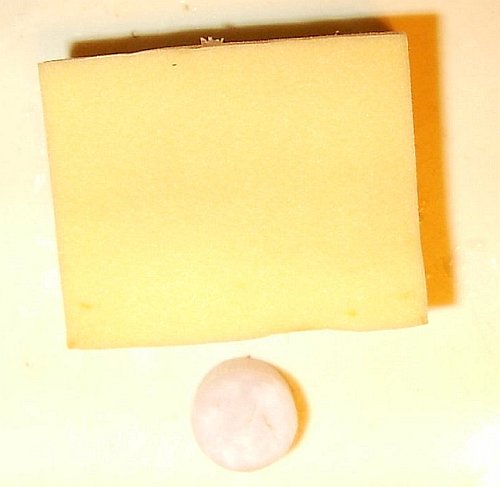

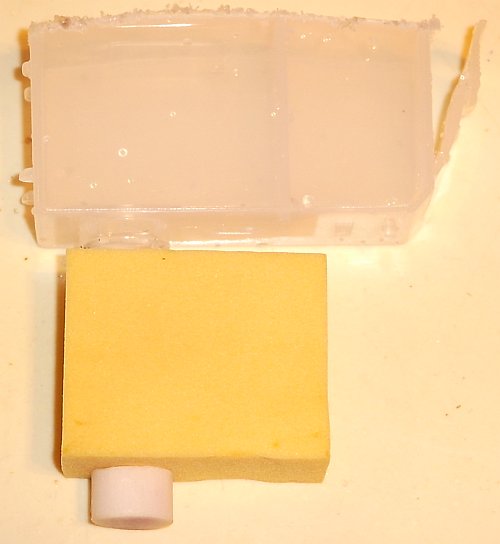

Guys, thanks so much for your images... "a picture is worth a thousand words"... well, it's true and I'd rather spend 2 mins taking / posting a few pictures than typing 5000 words!

By the way, I've copied your posts into the nifty-stuff gallery and edited your posts to point to those images. This will make sure that the images are always available.

http://www.nifty-stuff.com/gallery/inkjet-refill-1

By the way, I've copied your posts into the nifty-stuff gallery and edited your posts to point to those images. This will make sure that the images are always available.

http://www.nifty-stuff.com/gallery/inkjet-refill-1