I have reason to believe that there are failure modes on the printheads that seem on the surface to be a "clog" to the casual observer. To the more experienced, they would point to kogation issues being disguised as a clog. While less frequent, there is also real physical wear within the printhead chamber and heaters and the nozzle opening itself and then the more insidious electrical/electronic failure.

Canon heads must use an addressing system with a decoding IC on the rear of the contact board. I have seen one situation where the logic board had a failure in one of the address lines and it systematically destroyed each printhead that was inserted. Two heads were sacrificed. Worse yet, the faulty logic board did not indicate any failure. Only when the printheads were placed into another printer they were diagnosed as a faulty printhead.

As to proving it, it would be difficult and expensive unless you were given access to unlimited amounts of printheads like Canon R&D.

Here's something for you guys who have never seen inside one of these heads. They are quite simple heads physically until you get into the nozzle plate and that is where all the action is.

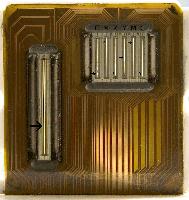

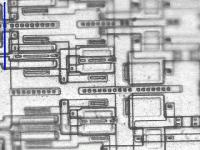

The IC that is behind the contact plate

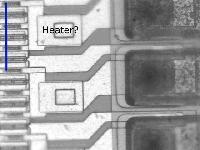

What's behind that nozzle plate/printhead plate?

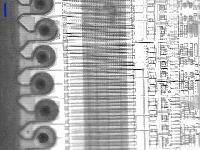

The 6 ink channels of the i950/960

Notice the wells at the end of the ink channels, these are there to maintain a wicking action and ensure that the ink is there for the head even at the end through capillary forces. If the well runs dry, you can get bad ink feed issues at the ends. Note as well that the plate is all that seals all the separate ink colors. Sometimes the plate bonding goes bad and you get cross-contamination between the colors. I must admit though that when these were taken apart, there didn't seem to be any bonding. So I wonder if the surface tension of the ink and the small gap is all that prevent cross contamination. These pics are about a year old so my memory is a bit off.

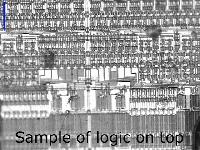

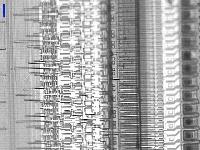

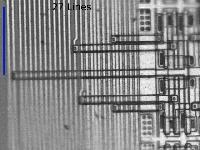

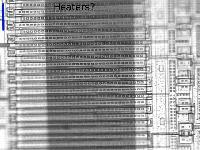

Pay attention to this, this head has 3,072 nozzles with equal amounts to each of the six colors in this head. Look carefully at the wires, there aren't 3,072 / 2 wires. Maybe someone can figure out the decoding addressing by counting the lines but it seems to me that there might be more decoding going on at the nozzle plate or maybe each nozzle is actually not separately addressed! but shoot in groups! Now this would explain a lot as to how Epson gets away with much fewer nozzles yet can retain an equally smooth gradation.

All just speculation above but interesting nonetheless.

Canon heads must use an addressing system with a decoding IC on the rear of the contact board. I have seen one situation where the logic board had a failure in one of the address lines and it systematically destroyed each printhead that was inserted. Two heads were sacrificed. Worse yet, the faulty logic board did not indicate any failure. Only when the printheads were placed into another printer they were diagnosed as a faulty printhead.

As to proving it, it would be difficult and expensive unless you were given access to unlimited amounts of printheads like Canon R&D.

Here's something for you guys who have never seen inside one of these heads. They are quite simple heads physically until you get into the nozzle plate and that is where all the action is.

The IC that is behind the contact plate

What's behind that nozzle plate/printhead plate?

The 6 ink channels of the i950/960

Notice the wells at the end of the ink channels, these are there to maintain a wicking action and ensure that the ink is there for the head even at the end through capillary forces. If the well runs dry, you can get bad ink feed issues at the ends. Note as well that the plate is all that seals all the separate ink colors. Sometimes the plate bonding goes bad and you get cross-contamination between the colors. I must admit though that when these were taken apart, there didn't seem to be any bonding. So I wonder if the surface tension of the ink and the small gap is all that prevent cross contamination. These pics are about a year old so my memory is a bit off.

Pay attention to this, this head has 3,072 nozzles with equal amounts to each of the six colors in this head. Look carefully at the wires, there aren't 3,072 / 2 wires. Maybe someone can figure out the decoding addressing by counting the lines but it seems to me that there might be more decoding going on at the nozzle plate or maybe each nozzle is actually not separately addressed! but shoot in groups! Now this would explain a lot as to how Epson gets away with much fewer nozzles yet can retain an equally smooth gradation.

All just speculation above but interesting nonetheless.