You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Longtime lurker willing to enter 3D

- Thread starter Artur5

- Start date

- Thread starter

- #92

Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,298

- Reaction score

- 1,624

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150,Pro10s,i3Mk3s+,Voron2.4

DIsclaimer : I decline any responsibility for whatever damages that may occur to your CR10 printers.Well out of curiosity and near persistence from @Artur5, I decided to buy a 1 kg roll of Polycarbonate, but I don’t have anything specific to print right now, so will have to find a wordy cause to test it out on when the timecomes.

It’s going to be interesting because of the higher temperatures needed to print the Polycarbonate filament, because I’ve never gone above 240c on my nozzle and 60c on the bed, but the slower print speed won’t be an issue.

If this works, it might spur me on to trying PETG and ABS again, but I did find their smell very untasteful, so let’s see how this Poly-C is, and I won’t know till I get it from AliExpress..

I’ll set up a heated filament box for it and try keep the humidity as low as possible.. I want to give it a fair chance..

This is what I plan to start with…

Print Speed:- 40mm/s

Nozzle Temp:- 260c

Bed Temp:- 100c

Sometimes you surprise me @The Hat. I purchased just a 50g. sample of PC to see how it works on my Prusa and you got 1kg for a start !.

My first try was OK. but much more experimentation is needed. My printer can, in theory, endure temperatures up to 300C because it has an all-metal heatbreak but your CR10s have a teflon tube. Now I see that you have read @ninj's post on this matter. I hope that Capricorn tube is the solution.

Read also what @ninj ( and I ) say about all-metal heatbreaks. Not perfect either.

Update : I'm sorry to inform that heat creep and subsequent jams aren't limited to PLA. It seems that polycarbonate isn't free from that either.

Intending to try something bigger than a small shroud, I tried a polycarbonate Benchy

It went OK for 90 minutes and, suddenly, .. JAM !

A pity because until then it was printing nice. No, you don't get results so smooth and detailed as PLA. That PC Benchy wouldn't pass the test as a successful PLA model even if ithe print had finished well. Defects are visible specially with small models like this one. Anyway, what matters for fonctional parts is that they're tough and heat enduring, not pretty.

PS;: I expect you purchased a Chinese brand of PC ?.

Depending on the additives of the blend, they can require dfferent settings for temperatures, retractions, etc.

Last edited:

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 120

- Reaction score

- 151

- Points

- 193

So, like you, I decided to purchase a new heatbreak at Aliexpress. More to the point, a bi-metal unit from Triangle-Labs. That one won't have the internal step and, I hope, it will be more efficient insulating the heat than the stainless steel model.

Let's wait for the arrival of my order and see what happens.

I was thinking about those Triangelab bi-metal heat breaks, but heard conflicting reports about them. Let me know how you get on.

Yes, just a cheap "micro-swiss" clone. But this has the advantage, unlike the genuine article, that the heat-block can take a thermistor cartridge (that is, if the photo can me believed). It surprises me that many all-metal hotends (even expensive ones) only accept the standard thermistors that have PTFE-covered wires screwed to the heat-block.Please, feel free to tell us what happens with the one you purchased. I gather you got the whole hotend unit, not just the heatbreak ?.

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 120

- Reaction score

- 151

- Points

- 193

I decided to go off and buy the Creality Capricorn 1Meter Bowden PTFE Tubing and am hoping to get it when they sort out their Feckin checkout system..

Some people get extruder clicking problems with Capricorn tubing because it's too tight for some filament. I recently did the 'hotend fix' that involves putting just a few cm of Capricorn tubing into the hotend, with the standard tubing going from the extruder to the top of the hotend. See

- Thread starter

- #95

Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,298

- Reaction score

- 1,624

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150,Pro10s,i3Mk3s+,Voron2.4

I saw in the video linked below that design with the thermistor screwed to the heat block.

Prusa uses the standard V6 from E3D, so I didn't understand at first what did you mean. If you ask me, it's way better a thermistor cartridge inserted into a separated hole of the block and secured by a grub screw.

I thought of replacing the whole hotend with a Dragonfly, but that's quite more expensive than changing the heatbreak. At the last moment I ordered also a plated copper heat block. It should last longer than the standard from aluminum and it has better thermal conductivity as well.

Prusa uses the standard V6 from E3D, so I didn't understand at first what did you mean. If you ask me, it's way better a thermistor cartridge inserted into a separated hole of the block and secured by a grub screw.

I thought of replacing the whole hotend with a Dragonfly, but that's quite more expensive than changing the heatbreak. At the last moment I ordered also a plated copper heat block. It should last longer than the standard from aluminum and it has better thermal conductivity as well.

Last edited:

- Joined

- Nov 3, 2004

- Messages

- 3,065

- Reaction score

- 1,429

- Points

- 337

- Location

- Bay Area CA

- Printer Model

- CR-10, i560 ,MFC-7440N

I've been thinking about doing this with my CR-10. I even have legit Capricorn on the ready in my supplies.I recently did the 'hotend fix' that involves putting just a few cm of Capricorn tubing into the hotend, with the standard tubing going from the extruder to the top of the hotend. See

... it's just hard for me to mess with something that's "working" since I'm often inclined to make things worse when trying to fix a problem that doesn't really exist. LOL!

- Joined

- Jan 18, 2010

- Messages

- 15,789

- Reaction score

- 8,819

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

Well Creality got back to me this morning, and I was able to order their Capricorn PTFE Tubing, so it will be a wait and see game as to which gets to me first, the filament or the tubing, I know @Artur5 doesn’t like Chinese filament, so that too will be wait and see as to their quality..

I am not sold on this Swiss hotend idea altogether as the answer to high nozzle temperature, it looks much the same as the hotend fix that @ninj used, at least with ninj fix, it negates the need for all the new parts..

I am not sold on this Swiss hotend idea altogether as the answer to high nozzle temperature, it looks much the same as the hotend fix that @ninj used, at least with ninj fix, it negates the need for all the new parts..

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 120

- Reaction score

- 151

- Points

- 193

The main purpose of the "fix" is to prevent the tube from riding up away from the nozzle and causing extrusion problems. Using Capricorn tubing has the side-effect of allowing slightly higher temperatures to be used - OK for careful experimentation but not really a long-term substitute for an all-metal hotend, which has a heatbreak without any PTFE tubing. Another possible option is to replace just the heatbreak with a titanium or bi-metalic one (but be prepared to polish the inner surface and/or season with oil like a wok).

- Thread starter

- #99

Artur5

Printer Master

- Joined

- Jan 24, 2011

- Messages

- 1,298

- Reaction score

- 1,624

- Points

- 278

- Location

- Kmt. 0.

- Printer Model

- MB5150,Pro10s,i3Mk3s+,Voron2.4

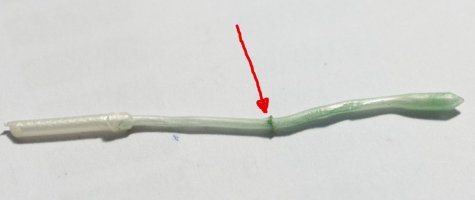

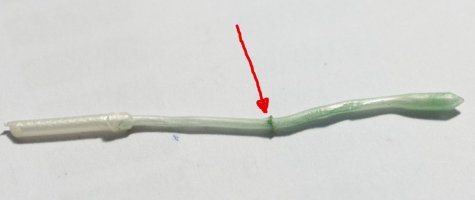

Keeping with the subject of the occasional jams of my Prusa MK3S+

Below is a picture of a cold pull with white PLA.

I did it to clean the rests of the glitter green PLA that gives me trouble,

Pointed with a red arrow you see clearly the shape left by the internal step of the heatbreak, This is where the green filament got stuck eventually.

To all Prusa owners here ( if any ), there or everywhere, please be aware of this issue. If you’re not going to install the Multimaterial system, do yourself a favor and replace the original heatbreak with a standard unit. Prusa hasn’t them anymore, but there’re plenty of E6 compatible heatbreaks on Aliexpress, Ebay, Amazon..

Below is a picture of a cold pull with white PLA.

I did it to clean the rests of the glitter green PLA that gives me trouble,

Pointed with a red arrow you see clearly the shape left by the internal step of the heatbreak, This is where the green filament got stuck eventually.

To all Prusa owners here ( if any ), there or everywhere, please be aware of this issue. If you’re not going to install the Multimaterial system, do yourself a favor and replace the original heatbreak with a standard unit. Prusa hasn’t them anymore, but there’re plenty of E6 compatible heatbreaks on Aliexpress, Ebay, Amazon..

Last edited:

- Joined

- Jan 18, 2010

- Messages

- 15,789

- Reaction score

- 8,819

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

No worries @Artur5, I am quite capable of brandjacking my printer up all by myself without consent, that comes naturally to me, and I couldn’t imagine buying a small amount of filament and then waiting another 4 weeks, after all it's only money.. Life’s to Feckin short..DIsclaimer : I decline any responsibility for whatever damages that may occur to your CR10 printers.

It’s great to see @Artur5 has now started to upgrade his 3D printer, I can recall him saying he wouldn’t, Covid is not the only show in town that’s contagious… welcome to the 3D Printaholic club..At the last moment I ordered also a plated copper heat block. It should last longer than the standard from aluminum and it has better thermal conductivity as well.

Latest posts

-

-

-

Epson Artisan 835 - What are causing these microscopic line streaks?

- Latest: Ink stained Fingers

-

do inks and dyes contain glycerin and glycol?

- Latest: Ink stained Fingers

-